Bushel Plus Tool Delivers a New Way to Measure and Minimize Harvest Loss – Grain Journal

Report on Mitigating Agricultural Harvest Loss for Enhanced Profitability and Sustainable Development

Executive Summary

In the current agricultural landscape, significant financial and resource losses occur during the harvesting of staple crops. These post-harvest losses represent a direct threat to farm profitability and undermine global food security efforts. This report examines the causes and impacts of combine harvester inefficiencies and presents a technological solution for their mitigation. The adoption of precision measurement tools aligns directly with key United Nations Sustainable Development Goals (SDGs), particularly SDG 2 (Zero Hunger) and SDG 12 (Responsible Consumption and Production), by converting on-farm losses into secured food and revenue.

The Challenge of Post-Harvest Loss in Agriculture

Economic Impact on Primary Producers

Inefficient harvesting directly translates to substantial revenue loss for farmers. The financial implications are significant across various crops:

- Corn: A 3% harvest loss on a 200 bushel-per-acre yield can result in a financial deficit of $24.30 per acre. Over a 1,000-acre farm, this amounts to a $24,300 loss in potential revenue. A 5% loss escalates this figure to $40,500.

- Soybeans: For a 70 bushel-per-acre crop, a 3% loss equates to $21.11 per acre, or $21,110 over 1,000 acres. This loss increases to over $35,000 at a 5% loss rate.

These losses critically affect farm viability, impacting livelihoods and hindering progress towards SDG 1 (No Poverty) and SDG 8 (Decent Work and Economic Growth) in rural economies.

Implications for Global Food Security and Sustainability

On-farm grain loss is a major component of post-harvest losses, which compromise global food supply chains. Reducing these losses is essential for achieving sustainable production patterns. This challenge is explicitly addressed by SDG 12, Target 12.3, which aims to halve food losses along production and supply chains by 2030. By leaving a significant percentage of yield in the field, conventional harvesting practices work against the objectives of SDG 2 (Zero Hunger), as potentially available food is wasted at the first point of collection.

Causal Factors and Deficiencies in Measurement

Operational Inefficiencies in Combine Harvesters

Combine harvesters, while technologically advanced, require precise calibration to operate efficiently. Key settings, if misaligned, are a primary cause of grain loss.

- Rotor Speed: An improperly calibrated rotor speed can damage kernels or process material too quickly, leading to loss.

- Fan Speed: Incorrect fan speeds can result in poor separation, blowing grain out of the machine along with chaff.

A delicate balance of these settings is required to maximize grain retention, but this balance is often unachieved due to a lack of accurate performance data.

Limitations of Standard Calibration Practices

Current methods for calibrating combines are often insufficient for achieving optimal performance.

- Factory Presets: Manufacturer settings provide a baseline but cannot account for specific field conditions, crop variations, or machine wear.

- In-Cab Loss Sensors: Integrated sensors provide an estimate of loss but lack the precision required for fine-tuning. Their accuracy is contingent upon being calibrated against real-world, physical loss measurements.

Without a physical, in-field measurement to establish a benchmark, operators are unable to accurately assess and correct for losses, making it impossible to manage what is not precisely measured.

A Technological Solution for Precision Harvest Management

The Bushel Plus SmartPan System

To address the need for accurate, real-time data, Bushel Plus has developed the SmartPan System, a remote drop pan solution designed for precise harvest loss measurement. The system provides actionable data through a streamlined process:

- Sample Collection: A magnetic drop pan is remotely deployed from underneath the combine during operation to collect a sample of the material being ejected.

- Separation: The collected sample is processed with an air separator to remove chaff and debris, isolating the clean grain that was lost.

- Measurement and Analysis: The clean grain is weighed using a digital scale, and the data is entered into a mobile application. The app instantly calculates the loss in bushels per acre, providing a clear and actionable metric.

This process allows operators to move from estimation to empirical knowledge, enabling targeted adjustments that immediately reduce waste. The system is compatible with all major combine-harvested crops, including corn, soybeans, wheat, rice, and canola, and is utilized by leading equipment manufacturers such as John Deere, Case IH, and New Holland.

Alignment with Sustainable Development Goals (SDGs)

The implementation of precision harvest loss measurement technology is a direct contribution to several critical SDGs.

- SDG 2 (Zero Hunger): By reducing on-farm food loss from as high as 8% to under 1%, this technology increases the amount of food available from existing agricultural land, enhancing food security without requiring additional resource inputs.

- SDG 12 (Responsible Consumption and Production): The system provides a practical and effective tool for farmers to meet the objectives of Target 12.3, which specifically calls for the reduction of post-harvest losses. It promotes a more efficient and sustainable production model.

- SDG 1 (No Poverty) & SDG 8 (Decent Work and Economic Growth): By turning lost yield into recovered revenue, the technology directly improves farmer profitability. This strengthens the economic foundation of agricultural communities, fostering sustainable growth and improving livelihoods.

Conclusion

The failure to accurately measure and manage combine grain loss represents a significant and preventable inefficiency in modern agriculture. This oversight leads to substantial financial losses for farmers and exacerbates global food waste. The adoption of precision tools like the SmartPan System provides a direct, field-proven method to optimize harvest efficiency. By enabling data-driven calibration, such technologies empower farmers to protect their investments, enhance profitability, and make a tangible contribution to achieving global Sustainable Development Goals.

Analysis of Sustainable Development Goals (SDGs) in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

-

SDG 2: Zero Hunger

This goal is central to the article, which focuses on agricultural production and efficiency. By addressing the issue of harvest loss, the article directly relates to ensuring food security and promoting sustainable agriculture. Reducing the amount of grain left in the field means more food is available from the same amount of land and resources, contributing to the overall food supply.

-

SDG 12: Responsible Consumption and Production

The article’s core theme is the reduction of food losses at the production stage of the supply chain. It highlights how inefficient harvesting practices lead to significant waste (“post-harvest losses”). The promotion of measurement and optimization techniques is a direct call for more responsible and sustainable production patterns in agriculture.

-

SDG 8: Decent Work and Economic Growth

The economic viability of farming is a key issue discussed. The article quantifies the financial impact of harvest loss on farmers, stating that a 5% loss in corn can cost a farmer “$40,500” over 1,000 acres. By providing solutions to reduce this loss, the article addresses the need to improve the economic productivity and profitability of farming, which supports sustained economic growth for agricultural communities.

-

SDG 9: Industry, Innovation, and Infrastructure

This goal is addressed through the article’s focus on technological innovation as a solution to an industrial problem. The “SmartPan System

” is presented as an “advanced remote drop pan solution” that upgrades the process of harvesting. This highlights the role of innovation and technology in making agricultural industries more efficient, resilient, and sustainable.

” is presented as an “advanced remote drop pan solution” that upgrades the process of harvesting. This highlights the role of innovation and technology in making agricultural industries more efficient, resilient, and sustainable.

2. What specific targets under those SDGs can be identified based on the article’s content?

-

Target 12.3: Halve Food Waste and Reduce Food Loss

This is the most directly relevant target. The article’s entire premise is built around reducing “post-harvest losses” of crops like corn, soybeans, and wheat. The text explicitly states, “Combine grain loss is one of the biggest invisible threats to profitability,” and the proposed solution aims to minimize this loss, directly aligning with the goal of reducing food losses along production chains.

-

Target 2.3: Double the Productivity and Incomes of Small-Scale Food Producers

The article emphasizes improving farmer profitability by reducing waste. By turning “lost yield into recovered revenue,” farmers can significantly increase their income from the same plot of land. The article notes that reducing loss from 8% to under 1% provides a massive return on investment, directly contributing to the economic well-being and productivity of food producers.

-

Target 2.4: Ensure Sustainable Food Production Systems

By optimizing combine settings and reducing waste, farmers are implementing more sustainable and resilient agricultural practices. This ensures that the resources invested in production—”seed, fertilizer, crop protection, fuel, and labor”—are not wasted. Efficient harvesting is a key component of a sustainable food production system that maximizes output while minimizing waste.

-

Target 8.2: Achieve Higher Levels of Economic Productivity Through Technological Upgrading and Innovation

The article champions the use of the SmartPan System

as a technological upgrade to traditional harvesting methods. It argues that relying on “factory combine presets or in-cab loss sensors” is insufficient and that this innovation allows for precise measurement and adjustment. This adoption of technology leads directly to higher economic productivity for the farmer by minimizing financial losses.

as a technological upgrade to traditional harvesting methods. It argues that relying on “factory combine presets or in-cab loss sensors” is insufficient and that this innovation allows for precise measurement and adjustment. This adoption of technology leads directly to higher economic productivity for the farmer by minimizing financial losses.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

-

Percentage of Harvest Loss

This is a direct and quantifiable indicator mentioned throughout the article. It provides specific figures, such as potential losses of “3%” or “5%,” and notes that users of the new technology have “reduced losses from as high as 8% down to under 1%.” This metric directly measures progress for Target 12.3 and is a component of the official SDG Indicator 12.3.1 (Food Loss Index).

-

Financial Loss/Gain per Acre or Farm

The article provides concrete financial indicators to illustrate the impact of harvest loss. For example, it calculates a 3% loss in corn as “$24.30” per acre, which amounts to “$24,300 in lost revenue” over 1,000 acres. This financial metric is a clear indicator of farmer income and profitability, relevant to measuring progress for Target 2.3.

-

Volume of Crop Lost/Saved (Bushels per Acre)

The article implies this indicator by translating percentage loss into volume. For corn, “a 3% harvest loss on a 200 bushel-per-acre yield… equates to 6 bushels left in the field.” Measuring the volume of grain saved is a direct indicator of increased agricultural productivity and reduced food loss, relevant to Targets 2.3 and 12.3.

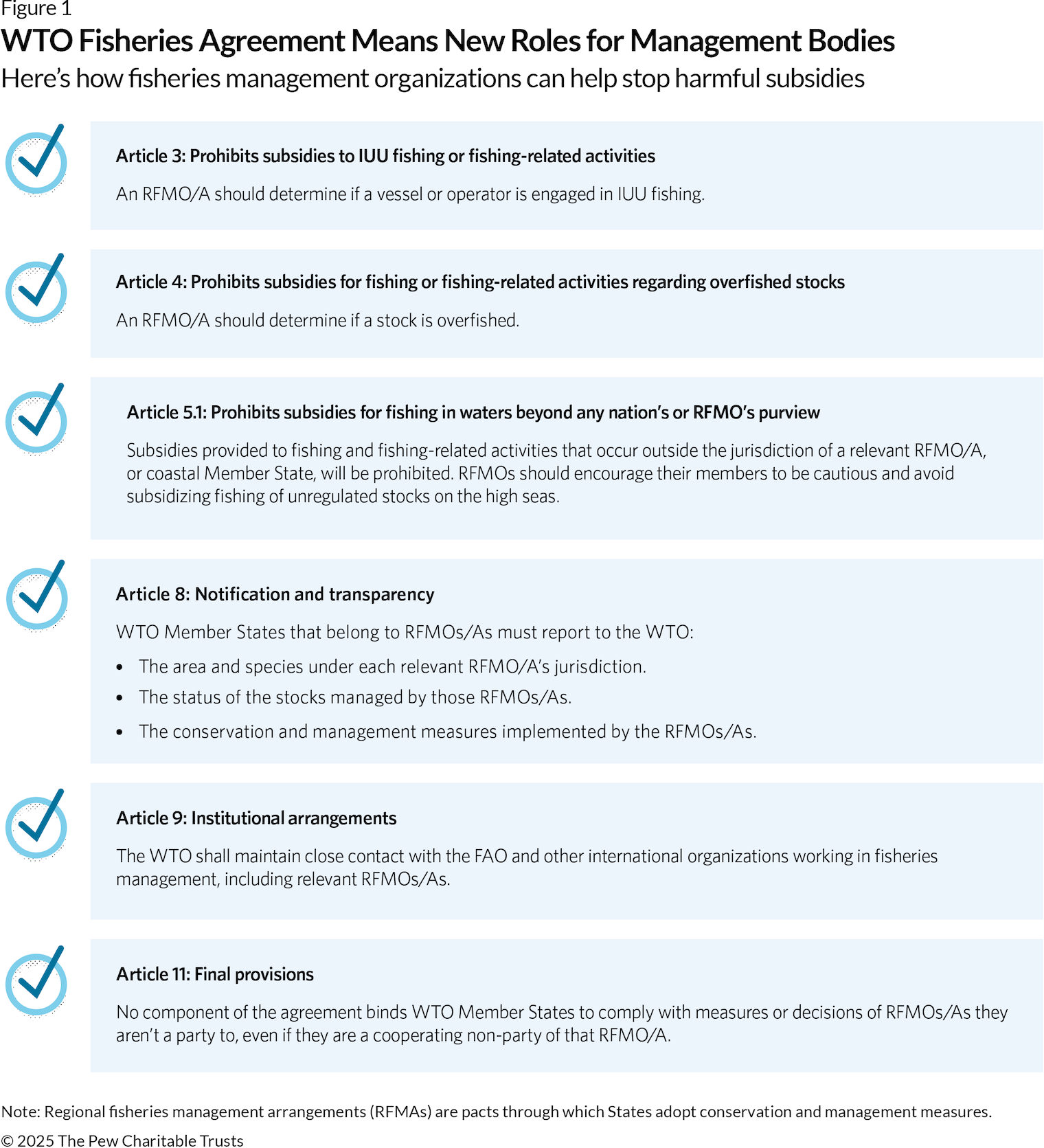

4. Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators Identified in the Article |

|---|---|---|

| SDG 2: Zero Hunger |

2.3: Double the agricultural productivity and incomes of small-scale food producers.

2.4: Ensure sustainable food production systems and implement resilient agricultural practices. |

– Financial gain from recovered revenue (e.g., saving “$24,300”). – Volume of crop saved (e.g., recovering 6 bushels per acre). – Increased efficiency of inputs (seed, fertilizer, fuel). |

| SDG 12: Responsible Consumption and Production | 12.3: By 2030, halve per capita global food waste… and reduce food losses along production and supply chains, including post-harvest losses. | – Percentage of harvest loss (e.g., reducing loss from “8% down to under 1%”). |

| SDG 8: Decent Work and Economic Growth | 8.2: Achieve higher levels of economic productivity through… technological upgrading and innovation. | – Financial loss per acre due to inefficiency (e.g., “$40,500” at 5% loss). – Return on investment (ROI) from adopting new technology. |

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency. | – Adoption of advanced technology (SmartPan System ) by farmers and manufacturers. ) by farmers and manufacturers.– Increased precision and accuracy in harvesting operations. |

Source: grainjournal.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

.jpg?h=50da7ea4&itok=DTgFLdpn#)