Optimizing ‘Green’ Ammonia Production with Raman Spectroscopy – chemengonline.com

Report on the Role of Raman Spectroscopy in Sustainable Green Ammonia Production

Executive Summary

The production of “green” ammonia, utilizing renewable energy sources, represents a critical advancement in industrial decarbonization, directly supporting several United Nations Sustainable Development Goals (SDGs). This report details the green ammonia production process, its market growth, and the operational challenges in maintaining quality. It further analyzes the integration of Raman spectroscopy as an innovative monitoring technology that enhances process efficiency and product purity. The adoption of this technology is instrumental in advancing SDG 7 (Affordable and Clean Energy), SDG 9 (Industry, Innovation, and Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action) by ensuring the viability and sustainability of green ammonia synthesis.

Green Ammonia: A Cornerstone for Sustainable Industrialization

Production Process and Contribution to SDG 7

Green ammonia is produced via the Haber-Bosch process, a method traditionally reliant on fossil fuels. The innovation lies in sourcing the required hydrogen (H₂) from water electrolysis powered entirely by renewable energy sources such as solar, wind, or hydropower. This shift is a direct contribution to SDG 7 (Affordable and Clean Energy) by creating demand for and utilizing clean energy, thereby promoting the transition away from a carbon-based energy infrastructure. Nitrogen (N₂) is sourced from the air, and the two gases are reacted under high pressure and temperature to synthesize ammonia (NH₃). This sustainable production model minimizes the carbon footprint associated with one of the world’s most critical chemical commodities.

Alignment with SDG 9 and SDG 13

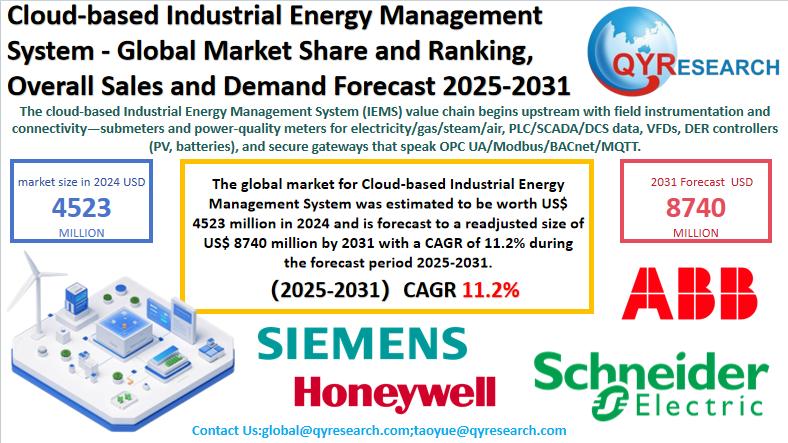

The development of green ammonia facilities, particularly dynamic installations designed to operate during periods of surplus renewable energy, fosters sustainable industrialization as outlined in SDG 9 (Industry, Innovation, and Infrastructure). This technological advancement supports the decarbonization of the chemical industry and contributes significantly to SDG 13 (Climate Action) by mitigating the greenhouse gas emissions inherent in conventional ammonia production. The rapid market expansion, with a projected compound annual growth rate (CAGR) of 90% from 2021 to 2030, underscores the global commitment to building resilient and sustainable industrial infrastructure.

Operational Challenges in Green Ammonia Quality Control

Impediments to Responsible Production (SDG 12)

Ensuring the quality and stability of green ammonia is paramount for its end-use applications, yet the process faces several challenges that can hinder the goals of SDG 12 (Responsible Consumption and Production). These challenges include:

- Impurities: Contaminants such as residual oxygen or nitrogen oxides can compromise the purity of the final product, affecting its performance and safety.

- Process Variability: The intermittent nature of renewable energy sources can lead to fluctuations in the production process, potentially affecting the consistency and quality of the ammonia output.

- Monitoring Deficiencies: Traditional quality control methods involving offline laboratory analysis are too slow to provide the real-time feedback needed to manage a dynamic, renewables-powered process efficiently.

Requirement for Advanced Analytical Tools

To overcome these obstacles and optimize sustainable production patterns, advanced measurement tools are essential. The primary requirements for such tools are:

- Accuracy: The ability to precisely measure the chemical composition of gas streams and detect trace impurities.

- Real-Time Analysis: The capacity to provide immediate data for instantaneous process adjustments, maximizing efficiency and minimizing waste.

- Non-Intrusive Monitoring: Methods that operate in-situ without disrupting the production flow or requiring sample extraction, thus ensuring data integrity.

Raman Spectroscopy: A Technological Enabler for Sustainable Development

Innovative Process Monitoring for Enhanced Efficiency

Raman spectroscopy emerges as a superior analytical solution for monitoring green ammonia production. This non-invasive optical technique provides a real-time molecular fingerprint of the process gas stream by measuring the inelastic scattering of light. It is highly sensitive to key components like hydrogen (H₂) and nitrogen (N₂), which are difficult for other analyzers to measure accurately. By providing continuous, in-situ data on the H₂/N₂ ratio and the presence of impurities, Raman spectroscopy allows for precise control over the synthesis loop. This capability directly supports SDG 9 by integrating advanced and clean technologies into industrial processes.

Contributions to Sustainable Operations and SDG Targets

The integration of Raman spectroscopy delivers multiple benefits that align with core SDG principles:

- Resource Efficiency (SDG 12): By enabling real-time optimization of the H₂/N₂ ratio, the technology ensures that raw materials and energy are used with maximum efficiency, minimizing waste and improving production yields.

- Process Reliability (SDG 9): Continuous, non-invasive monitoring reduces the need for maintenance and prevents downtime, contributing to the development of reliable and resilient industrial infrastructure.

- Clean Energy Optimization (SDG 7): Faster response times compared to traditional methods like gas chromatography allow production facilities to adapt rapidly to fluctuations in renewable energy supply, maximizing the use of clean power when it is most abundant and affordable.

- Cost-Effectiveness: By eliminating the need for consumables, sample transport, and extensive maintenance, Raman technology reduces operational expenditures, making sustainable production more economically viable.

Conclusion

The integration of Raman spectroscopy into green ammonia production is a significant technological advancement that reinforces the principles of sustainable development. By providing accurate, real-time, and non-intrusive process control, this technology addresses the primary challenges of quality assurance and operational efficiency. Its adoption is crucial for scaling up green ammonia production, thereby accelerating industrial decarbonization in line with SDG 13 (Climate Action). Furthermore, it exemplifies the type of innovation required by SDG 9 to build a sustainable industrial future and promotes the efficient use of resources as mandated by SDG 12 and SDG 7. Raman spectroscopy is, therefore, a key enabler in the transition toward a more sustainable, environmentally responsible, and efficient global chemical industry.

Analysis of Sustainable Development Goals in the Article

-

Which SDGs are addressed or connected to the issues highlighted in the article?

The article on green ammonia production and Raman spectroscopy addresses several Sustainable Development Goals (SDGs) by focusing on sustainable industrial practices, clean energy, and climate action.

- SDG 7: Affordable and Clean Energy

The article directly connects to this goal by defining “green ammonia” as ammonia produced using renewable energy sources, such as wind, solar, or hydropower. It emphasizes the shift away from fossil fuels (natural gas or coal) to power the Haber-Bosch process, thus promoting the use of clean energy in industrial applications. - SDG 9: Industry, Innovation, and Infrastructure

This goal is central to the article, which discusses the innovation of an established industrial process (ammonia production) to make it sustainable. It highlights the development of “fast or dynamic green ammonia installations” and the integration of advanced technologies like Raman spectroscopy to “upgrade infrastructure and retrofit industries to make them sustainable.” - SDG 12: Responsible Consumption and Production

The article addresses this goal by detailing a shift towards more sustainable production patterns. The production of green ammonia is presented as a method for “sustainable management and efficient use of natural resources” by replacing finite fossil fuels with renewable energy and water. The focus on process efficiency and minimizing waste (impurities) further aligns with this SDG. - SDG 13: Climate Action

The primary motivation for developing green ammonia, as described in the article, is to combat climate change. The text explicitly states that the process focuses on “minimizing carbon emissions,” supports the “decarbonization of the chemical industry,” and advances the “broader goal of achieving net-zero emissions.”

- SDG 7: Affordable and Clean Energy

-

What specific targets under those SDGs can be identified based on the article’s content?

Based on the article’s discussion, the following specific SDG targets can be identified:

- Target 7.2: By 2030, increase substantially the share of renewable energy in the global energy mix.

The article’s entire premise is based on this target. It describes how green ammonia production utilizes “hydrogen derived from water electrolysis powered by renewable energy,” directly contributing to increasing the share of renewables in the energy mix for industrial processes. - Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes.

The article exemplifies this target by describing the retrofitting of ammonia production with green technologies. The use of Raman spectroscopy is presented as a “clean and environmentally sound technology” that increases “process efficiency” and optimizes resource use (H₂/N₂ ratio). - Target 12.2: By 2030, achieve the sustainable management and efficient use of natural resources.

The shift from traditional ammonia production, which relies on fossil fuels, to green ammonia, which uses renewable electricity and water, is a direct application of this target. The article highlights how this improves the efficiency of resource use in the chemical industry. - Target 13.2: Integrate climate change measures into national policies, strategies and planning.

While not discussing national policies directly, the article presents green ammonia as a key industrial strategy to achieve climate goals. It states that the shift “supports the decarbonization of the chemical industry” and the “broader goal of achieving net-zero emissions,” which are central components of climate change measures.

- Target 7.2: By 2030, increase substantially the share of renewable energy in the global energy mix.

-

Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

The article mentions or implies several indicators that can be used to measure progress:

- Share of renewable energy in ammonia production: The core concept of “green ammonia” implies that the primary indicator is the percentage of production powered by renewable sources (wind, solar, hydropower) versus fossil fuels.

- Adoption of clean technologies: The article points to the “integration of Raman spectroscopy” as a measurable indicator of the adoption of advanced, efficient, and environmentally sound technologies in the chemical industry.

- Market growth of green ammonia: The article provides specific figures that serve as a direct indicator of progress. It states the market volume is “expected to grow at a compound annual growth rate (CAGR) of 90%, reaching around 1.6 million metric tons by 2030.” This growth directly measures the replacement of conventional ammonia with a sustainable alternative.

- Process efficiency improvements: The article implies that a key indicator is the improvement in process efficiency, which can be measured by the real-time, accurate monitoring of the hydrogen-to-nitrogen (H₂/N₂) ratio, leading to optimized production and reduced waste.

- Reduction in carbon emissions: Although not quantified, the reduction of carbon emissions is the fundamental goal. The volume of green ammonia produced can be used as a proxy indicator to calculate the amount of CO₂ emissions avoided compared to traditional production methods.

SDGs, Targets, and Indicators Table

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 7: Affordable and Clean Energy | 7.2: Increase substantially the share of renewable energy in the global energy mix. | Use of renewable energy sources (wind, solar, hydropower) to power water electrolysis for hydrogen production. |

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies. | Adoption rate of advanced analytical tools like Raman spectroscopy; Real-time measurement of process efficiency (e.g., H₂/N₂ ratio). |

| SDG 12: Responsible Consumption and Production | 12.2: Achieve the sustainable management and efficient use of natural resources. | Market volume of green ammonia produced, indicating the displacement of ammonia made from fossil fuels (projected to reach 1.6 million metric tons by 2030). |

| SDG 13: Climate Action | 13.2: Integrate climate change measures into policies, strategies and planning. | Reduction of carbon emissions from the ammonia production process; Growth in market size of green ammonia as a decarbonization strategy (projected CAGR of 116.5% from 2023 to 2030). |

Source: chemengonline.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

;Resize=805#)