A systematic approach towards a zero-waste water treatment: clay-carbon composite adsorbents made from drinking water treatment sludge – Nature

Executive Summary: Advancing Sustainable Development Goals through Innovative Water Treatment

This report details a systematic study on the production of clay-carbon composite adsorbents from drinking water treatment residuals. The research presents a novel, optimized process that transforms a waste product into a valuable material for water purification. This initiative directly addresses several United Nations Sustainable Development Goals (SDGs), particularly SDG 6 (Clean Water and Sanitation), SDG 9 (Industry, Innovation, and Infrastructure), SDG 11 (Sustainable Cities and Communities), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action). By developing a low-impact alternative to conventional activated carbon, this work provides a scalable, zero-waste solution that enhances water security, promotes a circular economy, and reduces the carbon footprint of the water treatment industry.

1. Introduction: The Nexus of Water Quality, Climate Action, and Sustainable Production

The global water sector faces a dual challenge: meeting increasingly stringent water quality standards while simultaneously reducing its environmental and carbon footprint. This challenge aligns directly with the ambitions of the UN SDGs.

- SDG 6 (Clean Water and Sanitation): European legislation mandates the removal of emerging contaminants like heavy metals and organic micropollutants to protect public health and aquatic ecosystems.

- SDG 13 (Climate Action): Concurrently, climate neutrality goals, such as the European Union’s target to reduce emissions by 55% by 2030, demand more sustainable industrial processes.

Adsorption using activated carbon (AC) is a cornerstone of advanced water treatment. However, conventional AC production, especially from fossil fuels, carries a significant environmental burden, contributing to CO₂ emissions and ecotoxicity. This practice is misaligned with SDG 12 (Responsible Consumption and Production). This study explores a sustainable alternative: upcycling drinking water treatment sludge—a voluminous waste stream—into effective adsorbents. This approach embodies the principles of a circular economy, contributing to:

- SDG 11 (Sustainable Cities and Communities): By managing urban waste streams more effectively.

- SDG 12 (Responsible Consumption and Production): By transforming waste into a resource and reducing reliance on virgin materials.

- SDG 9 (Industry, Innovation, and Infrastructure): By introducing innovative technology (a custom laboratory rotary furnace) and a statistically optimized production process to create a viable, eco-friendly industrial product.

2. Process Innovation and Optimization

2.1. Adsorbent Production Methodology

A novel, custom-designed laboratory rotary furnace was utilized for the thermal activation of dried water treatment sludge. This design improves upon traditional static furnaces, enhancing heat transfer and scalability, which is a critical step for industrial implementation and achieving SDG 9.

2.2. Statistical Process Optimization

A Central Composite Design (CCD), a sophisticated statistical methodology, was employed to systematically analyze and optimize the activation process. This represents the first comprehensive statistical analysis of this kind for water treatment residuals. The key variable factors investigated were:

- Heating Rate

- Heating Ramp Duration

- Steam Dosage (H₂O/N₂ ratio)

- Residence Time at Maximum Temperature

This rigorous approach ensures that the production process is not only effective but also resource-efficient, a core tenet of SDG 12.

3. Key Findings and Discussion

3.1. Material Characterization and Performance

The thermal activation process proved highly effective in enhancing the material’s properties.

- Surface Area Enhancement: The specific surface area of the sludge was increased nearly tenfold, from 26 m²/g in the raw material to a range of 112–201 m²/g in the activated adsorbents.

- Contaminant Removal: The produced adsorbents demonstrated effective removal of various organic pollutants, including ibuprofen, caffeine, diclofenac, and the dye brilliant blue FCF. This directly contributes to SDG 6.3 by improving water quality through pollution reduction.

3.2. Influence of Production Parameters

Response Surface Models (RSM) revealed the critical factors influencing adsorbent quality, providing a pathway for energy-efficient and optimized production in line with SDG 9 and SDG 12.

- Significant Factors: Heating rate (p

- Insignificant Factors: Contrary to expectations, residence time at maximum temperature had no significant influence, suggesting potential for energy savings by shortening this process step.

- Steam Dosage: The effect of steam was complex; it was beneficial at lower heating intensities but detrimental at higher intensities, highlighting the necessity of statistical modeling for process optimization.

4. A Zero-Waste Vision for Sustainable Water Treatment

4.1. Contribution to a Circular Economy

The on-site production of adsorbents from sludge exemplifies a zero-waste, circular economy model within a single facility. This directly supports SDG 12.5, which aims to substantially reduce waste generation through recycling and reuse.

4.2. Mass Balance and Scalability

A case study at the Roetgen Drinking Water Treatment Plant (DWTP) in Germany demonstrates the concept’s viability.

- The plant produces approximately 4.86 tons of dry sludge daily.

- Using the optimized process, this could yield ~2.8 tons of adsorbent per day.

- This quantity is sufficient to replace the plant’s entire need for conventional AC, with a significant surplus available for commercial sale.

This model not only eliminates waste disposal costs and environmental impacts but also creates a new revenue stream, fostering sustainable economic models for essential public services as envisioned in SDG 11.

4.3. Reducing Carbon Footprint and Import Dependency

By substituting fossil-fuel-derived AC with a locally produced, waste-derived alternative, this process significantly reduces the carbon footprint of water treatment operations, advancing SDG 13 (Climate Action). It also reduces dependency on imported AC, strengthening local supply chains and industrial resilience (SDG 9).

5. Conclusion and Future Outlook

This study successfully demonstrates a systematic and statistically robust approach to producing high-value adsorbents from drinking water treatment sludge. The findings confirm that key process parameters, particularly heating rate and ramp duration, are critical to optimizing adsorbent performance.

The proposed zero-waste model offers a powerful solution to the challenges at the intersection of water, waste, and energy. It provides a clear and scalable pathway for the water treatment industry to contribute meaningfully to multiple Sustainable Development Goals:

- SDG 6: By ensuring cleaner water through the removal of emerging pollutants.

- SDG 9: Through industrial innovation and the development of resilient, sustainable infrastructure.

- SDG 11: By creating more sustainable and resource-efficient municipal services.

- SDG 12: By pioneering responsible production and consumption patterns in a circular economy framework.

- SDG 13: By actively reducing the carbon emissions associated with water purification.

Future research will focus on expanding the application of these adsorbents for heavy metal removal and conducting a full life cycle assessment to quantify the environmental benefits, further strengthening the case for this sustainable technology.

Analysis of Sustainable Development Goals in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

-

SDG 6: Clean Water and Sanitation

The article’s primary focus is on improving water quality by developing advanced methods to remove contaminants. It directly addresses the need for cleaner drinking water and better wastewater treatment by creating novel adsorbents to eliminate organic micropollutants like pharmaceuticals (ibuprofen, caffeine, diclofenac) and other substances from water sources.

-

SDG 9: Industry, Innovation, and Infrastructure

The study centers on technological innovation. It describes the design of a “novel laboratory rotary furnace” and the development of a new, optimized process for producing adsorbents. This represents an effort to upgrade industrial processes (water treatment) with more sustainable and efficient technologies, as mentioned in the introduction regarding the need for “advanced wastewater treatment processes.”

-

SDG 12: Responsible Consumption and Production

The article promotes a circular economy model by proposing a “zero-waste concept.” It focuses on converting “water treatment residuals” (sludge), which is currently a waste product destined for incineration or landfills, into a valuable resource (eco-adsorbents). This directly addresses the goal of reducing waste generation through reuse and recycling.

-

SDG 13: Climate Action

A key motivation for the research is the high environmental impact and “CO₂ emissions” associated with conventional activated carbon production. The article explicitly states the goal is to “reduce the carbon dioxide footprint” of water treatment operations by substituting traditional adsorbents with a locally produced, sludge-derived alternative, thereby contributing to climate change mitigation.

-

SDG 14: Life Below Water

By effectively removing organic micropollutants such as ibuprofen and diclofenac from water, the developed technology helps prevent these harmful substances from entering and polluting aquatic ecosystems. The introduction notes the need to “protect and improve the quality of natural raw water sources,” which directly benefits life below water by reducing chemical contamination.

2. What specific targets under those SDGs can be identified based on the article’s content?

-

Target 6.3: By 2030, improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials, halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally.

The article directly supports this target by developing a technology to remove “hazardous chemicals” such as “organic micropollutants” (ibuprofen, diclofenac, caffeine) from water. The “zero-waste concept” of turning sludge into adsorbents is a form of “recycling and safe reuse.”

-

Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes.

The research aims to replace an energy-intensive and high-emission product (conventional activated carbon) with a “low-cost and environmentally friendly” alternative made from waste. The development of the “custom-made bench-scale rotary furnace” and the optimization of the thermal activation process are steps toward creating an “environmentally sound technology” for the water treatment industry.

-

Target 12.2: By 2030, achieve the sustainable management and efficient use of natural resources.

The article addresses this by proposing a method to reuse water treatment sludge, a waste material. This turns a disposal problem into a resource, reducing the need for raw materials like “fossil coal,” “wood or nutshells” that are traditionally used for activated carbon production, thus promoting more efficient use of resources.

-

Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.

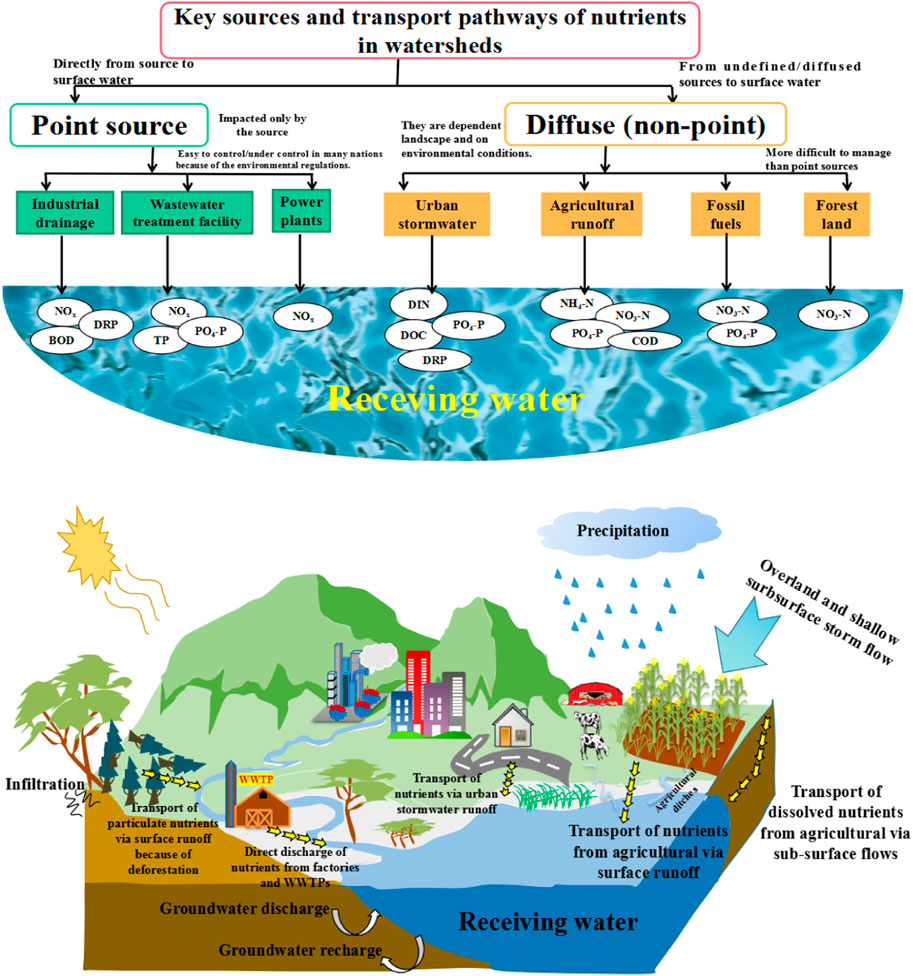

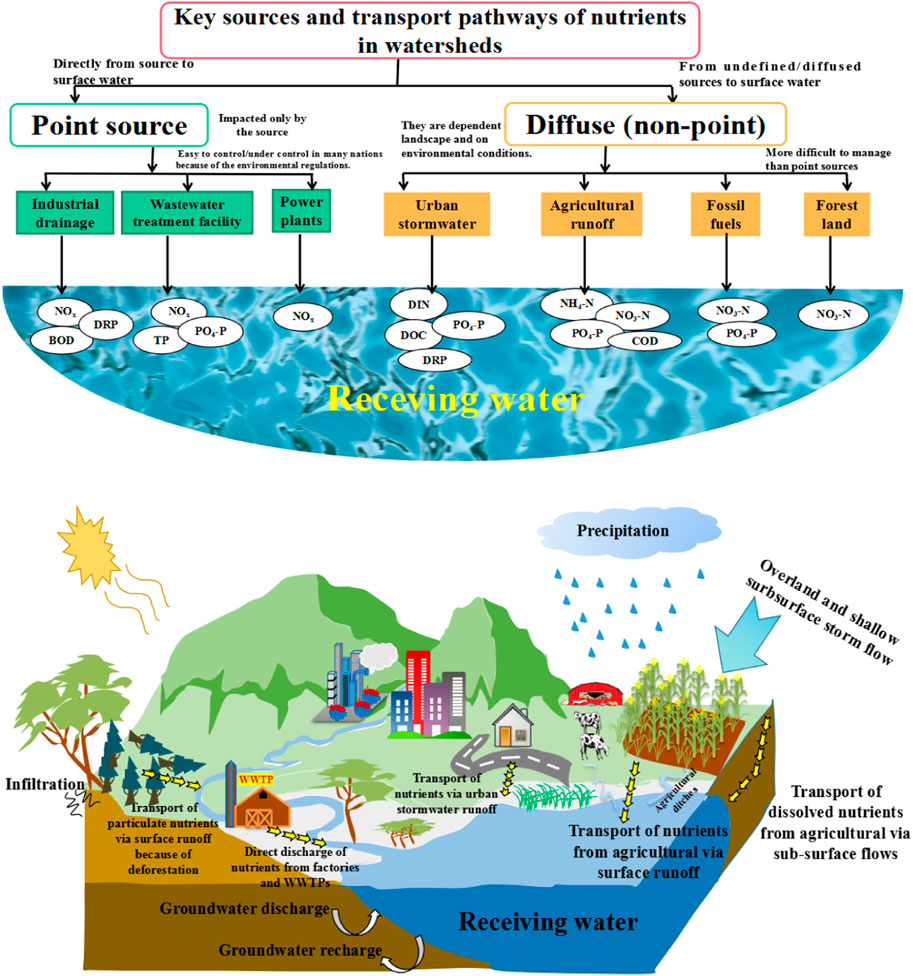

This is a central theme. The article details a process to recycle sludge (“approximately 40 m³ of dewatered sludge…is produced daily”) that would otherwise be “disposed of by waste incineration.” The “sludge recycling cycle” diagram illustrates a clear strategy for waste reduction and reuse.

-

Target 13.2: Integrate climate change measures into national policies, strategies and planning.

While the article is a scientific study, it provides a technological solution to a problem framed by climate policy, such as the “European Union’s Climate Law” which requires member states to “reduce their carbon emissions by at least 55% by 2030.” The proposed technology is a direct response to the need for industries to lower their carbon footprint.

-

Target 14.1: By 2020, prevent and significantly reduce marine pollution of all kinds, in particular from land-based activities, including marine debris and nutrient pollution.

The removal of micropollutants from drinking water and wastewater prevents these chemicals from being discharged into rivers and eventually reaching marine environments. The article’s focus on removing pharmaceuticals, which are persistent pollutants, directly contributes to reducing land-based chemical pollution of water bodies.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

-

Indicators for Target 6.3 & 14.1:

The article provides direct, measurable indicators of water quality improvement.

- Concentration of pollutants in water: The study measures the removal of specific micropollutants (ibuprofen, caffeine, diclofenac) from an initial concentration of “1 µg/L.” The final concentration after treatment is a direct indicator of water quality.

- Relative removal rates: The article calculates and presents “relative removal rates for all four substances” (Fig. 2), which is a quantitative measure of the technology’s effectiveness in reducing pollution.

-

Indicators for Target 9.4:

The article implies indicators related to the adoption and efficiency of the new technology.

- Adsorbent performance metrics: The “BET surface area” of the new adsorbents (“112 m²/g and 201 m²/g”) is a key performance indicator of the new production process compared to the raw material (“26 m²/g”).

- Process efficiency: The statistical analysis identifies optimal production parameters (e.g., “heating rate,” “ramp duration”) that can be used to measure and maximize the resource efficiency of the new technology.

-

Indicators for Target 12.2 & 12.5:

The article provides clear data for measuring waste reduction and resource efficiency.

- Amount of waste recycled: The article quantifies the daily production of sludge (“4.864 t/d” of dry matter) and the potential yield of the adsorbent (“~2.8 t/d adsorbent”). The ratio of waste input to product output is a direct indicator of recycling efficiency.

- Reduction in primary resource use: Progress can be measured by the amount of conventional activated carbon that is substituted. The article suggests “on-site production could fully substitute activated carbon.”

-

Indicators for Target 13.2:

The article implies an indicator for measuring climate action.

- CO₂ emissions per unit of product: The article cites the CO₂ footprint of conventional activated carbon (“9.5 kg CO₂/kg AC for the production of AC from fossil coal”). An implied indicator for the new technology would be its own CO₂ emissions per kg of adsorbent produced, which is expected to be significantly lower, thus measuring the reduction in carbon footprint.

4. Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators Identified in the Article |

|---|---|---|

| SDG 6: Clean Water and Sanitation | 6.3: Improve water quality by reducing pollution and minimizing the release of hazardous chemicals. |

|

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries to make them sustainable and adopt clean technologies. |

|

| SDG 12: Responsible Consumption and Production | 12.5: Substantially reduce waste generation through recycling and reuse. |

|

| SDG 13: Climate Action | 13.2: Integrate climate change measures into policies and planning. |

|

| SDG 14: Life Below Water | 14.1: Prevent and significantly reduce marine pollution from land-based activities. |

|

Source: nature.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0