Canon enters recycling system business with innovative technology, promoting circular economy with high-speed, accurate plastic sorting equipment capable of measuring even black plastic waste | Canon Global

Canon enters recycling system business with innovative technology, promoting circular economy with high-speed, accurate plastic sorting equipment capable of measuring even black plastic waste

TOKYO, June 6, 2024—Canon Inc. announced today that it will launch new plastic sorting equipment with innovative material identification technology. The equipment applies Raman spectroscopy technology to moving objects with a tracking mechanism to collectively detect the material types of plastic fragments with high accuracy, even when black plastic pieces are mixed with other colors, which has been conventionally challenging. Today, the company will begin widely accepting orders from the market for the “TR Series” which includes the “TR-S1510.”

Sustainable Development Goals (SDGs)

- Goal 12: Responsible Consumption and Production

- Goal 9: Industry, Innovation, and Infrastructure

Introduction

Canon Inc. has announced the launch of new plastic sorting equipment that utilizes innovative material identification technology. This equipment incorporates Raman spectroscopy technology and a tracking mechanism to accurately detect the material types of plastic fragments, even when black plastic pieces are mixed with other colors. By addressing the challenge of identifying black plastics, Canon aims to promote a circular economy and contribute to the achievement of the Sustainable Development Goals (SDGs).

Plastic Recycling and Material Identification

Currently, only approximately 20%1 of plastic waste generated in daily life is recycled as material for new products. The remaining plastic waste is either used as fuel or incinerated. To ensure the quality of recycled plastics, it is crucial to accurately identify the materials of plastic waste, such as ABS2 and polypropylene (PP). However, black plastics, commonly used in home electronics and automobile upholstery, pose a challenge in material identification due to their inability to transmit or reflect visible light. Conventional near-infrared spectroscopy3 is ineffective in identifying the materials of black plastics. Additionally, there is a need for higher accuracy and productivity in plastic sorting operations to accelerate plastic recycling.

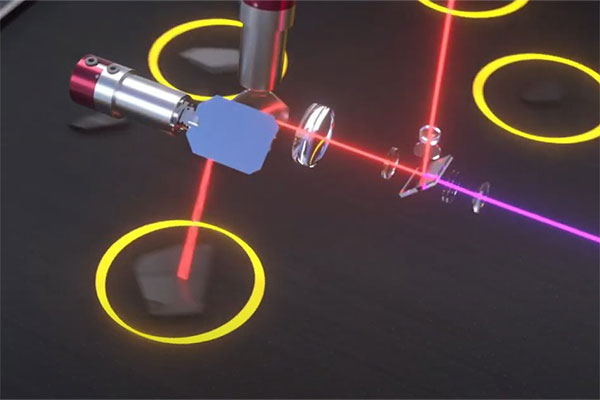

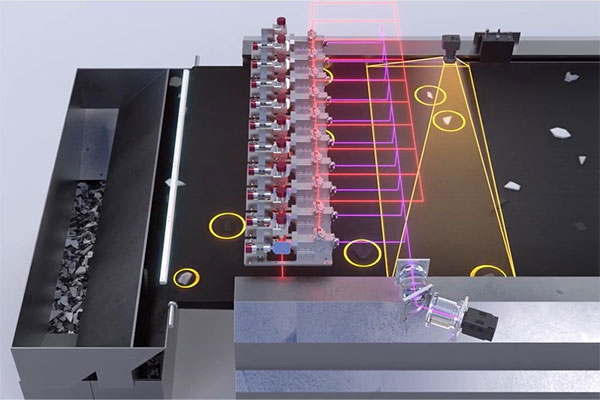

Innovative Technology for High-Speed, Accurate Plastic Sorting

Canon’s new plastic sorting equipment utilizes a proprietary tracking Raman spectroscopic method to rapidly sort all plastic pieces, including black plastics, with high precision. This technology overcomes the limitations of conventional near-infrared spectroscopy and enables the practical identification of black plastic pieces mixed with other colors. By improving the productivity of recycling plants, Canon aims to maximize material recycling and contribute to the achievement of the SDGs.

Key Features

- The equipment applies Raman spectroscopy technology to moving objects with a tracking mechanism.

- It can detect the material types of plastic fragments with high accuracy, even when black plastic pieces are mixed with other colors.

- The system maintains a conveyor speed of 1.5 meters per second and can sort up to 1 ton of plastic per hour.

- It can be customized according to a customer’s throughput and installation space by changing the module that tracks and measures the plastic pieces or the combination of conveyor belts.

Conclusion

With the launch of its new plastic sorting equipment, Canon enters the recycling system market and aims to build a circular economy by maximizing material recycling. By utilizing innovative technology and addressing the challenge of identifying black plastics, Canon contributes to the achievement of the SDGs, particularly Goal 12: Responsible Consumption and Production and Goal 9: Industry, Innovation, and Infrastructure.

References

- 1 “Plastic Products, Plastic Waste and Resource Recovery” published by the Plastic Waste Management Institute

- 2 Acrylonitrile Butadiene Styrene. A type of plastic that is highly resistant to heat and impact.

- 3 A method of measurement in which an object is illuminated with near-infrared light. Based on factors such as reflection and penetration of light, the object’s light absorption is measured, and the type of resin the object comprises can be determined.

- 4 By continuously moving the position of the laser, the target object is continuously illuminated by the laser, allowing for light to be reflected.

SDGs, Targets, and Indicators

-

SDG 12: Responsible Consumption and Production

- Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling, and reuse

- Indicator 12.5.1: National recycling rate, tons of material recycled

The article discusses Canon’s entry into the recycling system business with innovative plastic sorting equipment. This aligns with SDG 12, which focuses on responsible consumption and production. The target under SDG 12 that can be identified based on the article’s content is Target 12.5, which aims to reduce waste generation through prevention, reduction, recycling, and reuse. Canon’s plastic sorting equipment contributes to this target by improving the accuracy and productivity of plastic recycling.

The article also mentions that currently, only around 20% of plastic waste generated is recycled as material for new products, while the rest is used as fuel or incinerated. This information implies the need to measure the national recycling rate (Indicator 12.5.1) to track progress towards Target 12.5.

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 12: Responsible Consumption and Production | Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling, and reuse | Indicator 12.5.1: National recycling rate, tons of material recycled |

Copyright: Dive into this article, curated with care by SDG Investors Inc. Our advanced AI technology searches through vast amounts of data to spotlight how we are all moving forward with the Sustainable Development Goals. While we own the rights to this content, we invite you to share it to help spread knowledge and spark action on the SDGs.

Fuente: global.canon

Join us, as fellow seekers of change, on a transformative journey at https://sdgtalks.ai/welcome, where you can become a member and actively contribute to shaping a brighter future.