Stircor partners with Georgia water department to implement advanced drying technology – Wastewater Digest

Report on the Stircor and Cartersville Water Department Partnership for Sustainable Wastewater Management

Introduction: Advancing Sustainable Urban Infrastructure

On July 24, 2025, Stircor and the Cartersville Water Department in Georgia announced a strategic partnership to upgrade the city’s wastewater treatment facility. This collaboration focuses on implementing advanced biosolid drying technology, a critical step toward aligning the city’s operations with key United Nations Sustainable Development Goals (SDGs), particularly those concerning water, infrastructure, and sustainable communities.

Project Alignment with Sustainable Development Goals (SDGs)

The initiative directly contributes to several SDGs by transforming municipal waste into a valuable resource and enhancing environmental compliance. The primary goals supported include:

- SDG 6: Clean Water and Sanitation: The project enhances the management of wastewater and sanitation services by safely treating biosolids, preventing potential contamination and ensuring the protection of water resources.

- SDG 9: Industry, Innovation, and Infrastructure: By adopting Stircor’s innovative drying technology, Cartersville is upgrading its municipal infrastructure, making it more resilient, efficient, and environmentally sound.

- SDG 11: Sustainable Cities and Communities: This partnership improves the sustainability of urban services. By managing waste effectively at the source, it reduces the environmental footprint of the city and promotes a healthier community.

- SDG 12: Responsible Consumption and Production: The core of the project is to create a circular economy model for wastewater byproducts. It transforms biosolids, a waste stream, into a safe, reusable Class A material, significantly reducing waste generation.

Technological Implementation and Environmental Impact

The collaboration will overhaul the current biosolids management process at the Cartersville wastewater treatment plant, which processes up to 15 million gallons of wastewater daily. The implementation of Stircor’s technology involves a comprehensive, on-site solution.

- Advanced Drying Process: Stircor will install, operate, and maintain its specialized drying equipment at the facility.

- Volume and Waste Reduction: The technology significantly reduces the volume of biosolids, which lowers transportation costs and associated carbon emissions, contributing to climate action (SDG 13).

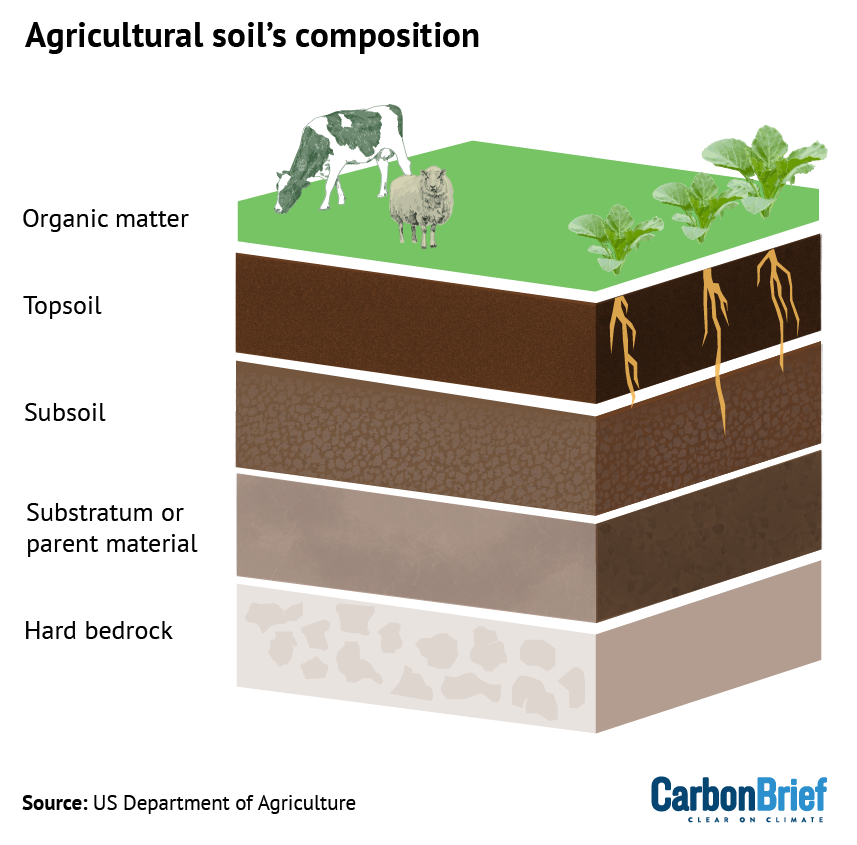

- Creation of Class A Biosolids: The end-product is a nutrient-rich, Class A material that meets the U.S. Environmental Protection Agency’s (EPA) Part 503 rule. This material is safe for land application, supporting soil health and sustainable agriculture (SDG 15).

Stakeholder Commitment to Sustainability

Leadership from both organizations emphasized the project’s role in advancing sustainable development.

Sidney Forsyth, Director of the Cartersville Water Department, stated that the partnership enables the city to “meet and exceed environmental regulations,” highlighting the initiative’s benefit to the community through the promotion of sustainability. This positions Cartersville as a leader in modern, responsible wastewater management practices, in line with the objectives of SDG 11.

Lincoln Day, Chief Revenue Officer of Stircor, reiterated the company’s mission to provide “cost-effective and environmentally friendly solutions” for biosolid disposal. He described the partnership as an embodiment of a shared commitment to sustainable practices and community well-being, directly supporting the principles of SDG 9 and SDG 12.

1. Which SDGs are addressed or connected to the issues highlighted in the article?

The article on the partnership between Stircor and the Cartersville Water Department addresses several Sustainable Development Goals (SDGs) related to water management, sustainable infrastructure, and community development. The primary SDGs identified are:

-

SDG 6: Clean Water and Sanitation

This goal is central to the article, as the project’s core purpose is to implement “advanced drying technology for the city’s wastewater treatment facility.” The initiative aims to improve the management of wastewater byproducts (biosolids), which is a critical component of ensuring clean water and sanitation for the community.

-

SDG 9: Industry, Innovation, and Infrastructure

The article highlights the adoption of “innovative drying solutions” and “advanced drying technology.” This directly connects to SDG 9, which promotes building resilient infrastructure and fostering innovation. The collaboration represents an upgrade of municipal infrastructure to make it more sustainable and efficient through the use of modern, environmentally sound technology.

-

SDG 11: Sustainable Cities and Communities

The project is a municipal initiative for the city of Cartersville, Georgia. By improving its wastewater management system, the city is working to “reduce the adverse per capita environmental impact of cities,” a key aspect of SDG 11. The article notes the initiative benefits the community by “promoting sustainability” and enhancing “community well-being.”

-

SDG 12: Responsible Consumption and Production

This goal is relevant because the technology transforms wastewater biosolids, a waste product, into “Class A materials” and a “nutrient-rich, safe end-product suitable for various applications.” This process aligns with the principles of a circular economy by reducing waste and creating valuable resources from it, contributing to more sustainable production and consumption patterns.

2. What specific targets under those SDGs can be identified based on the article’s content?

Based on the article’s focus, the following specific targets can be identified:

-

Target 6.3: Improve water quality by reducing pollution and treating wastewater

The article directly addresses this target. The partnership aims to “enhance our biosolids treatment process” at a wastewater treatment plant that processes up to “15 million gallons per day.” By transforming biosolids into “Class A materials” according to EPA standards, the project improves the quality of wastewater treatment and minimizes the potential for pollution from untreated waste.

-

Target 9.4: Upgrade infrastructure and industries for sustainability

The implementation of Stircor’s “advanced drying technology” is a clear example of upgrading infrastructure to make it more sustainable. The article states that this move positions Cartersville “at the forefront of modern wastewater treatment practices” and enhances the facility’s “efficiency and environmental compliance,” which is the essence of Target 9.4.

-

Target 11.6: Reduce the environmental impact of cities

This target focuses on reducing the adverse environmental impact of cities, with a special mention of “municipal and other waste management.” The project is a direct effort by the Cartersville Water Department to improve its management of municipal waste (biosolids), thereby reducing the city’s overall environmental footprint.

-

Target 12.5: Substantially reduce waste generation

The technology described in the article “significantly reduces biosolid volume.” Furthermore, it transforms the remaining material into a “safe end-product suitable for various applications.” This process embodies the principles of reduction and reuse, directly contributing to the goal of substantially reducing waste generation.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

The article implies several indicators that can be used to measure progress:

-

For Target 6.3 (Improve water quality):

An implied indicator is the quality and classification of the treated biosolids. The article specifies the goal is to produce “Class A materials, adhering to the stringent standards set by the U.S. Environmental Protection Agency’s (EPAs) Part 503 biosolids rule.” Achieving this classification is a direct measure of improved treatment and safety.

-

For Target 9.4 (Upgrade infrastructure):

The primary indicator is the adoption of clean and environmentally sound technology. The article’s announcement of the partnership and the “integrating [of] the company’s drying technology” serves as a qualitative indicator of progress in upgrading the city’s infrastructure with sustainable solutions.

-

For Target 11.6 (Reduce environmental impact of cities):

A key indicator is the volume of municipal waste (biosolids) safely managed and treated. The plant processes “up to 15 million gallons per day,” and the new technology will enhance the management of the resulting biosolids. Measuring the percentage of biosolids that are successfully converted to Class A material would be a quantifiable indicator of improved municipal waste management.

-

For Target 12.5 (Reduce waste generation):

The article mentions that the technology “significantly reduces biosolid volume.” Therefore, a direct indicator is the percentage reduction in the final volume of biosolids requiring disposal. Additionally, the quantity of the “nutrient-rich, safe end-product” created for reuse can be measured as an indicator of successful waste valorization.

4. Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators (Mentioned or Implied in the Article) |

|---|---|---|

| SDG 6: Clean Water and Sanitation | Target 6.3: By 2030, improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials, halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally. | Achievement of “Class A” material status for biosolids, as defined by the EPA’s Part 503 rule. |

| SDG 9: Industry, Innovation, and Infrastructure | Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and processes. | The implementation and integration of “advanced drying technology” into the city’s wastewater treatment facility. |

| SDG 11: Sustainable Cities and Communities | Target 11.6: By 2030, reduce the adverse per capita environmental impact of cities, including by paying special attention to air quality and municipal and other waste management. | The volume of municipal biosolids processed daily (from up to 15 million gallons of wastewater) that is sustainably managed through the new technology. |

| SDG 12: Responsible Consumption and Production | Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse. | The significant reduction in biosolid volume and the creation of a “nutrient-rich, safe end-product” suitable for reuse. |

Source: wwdmag.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

;Resize=805#)