Thermal Energy Storage: The Industrial World’s Hottest Batteries – Forbes

Report on Thermal Energy Storage and Sustainable Development

The global energy landscape is undergoing a critical transformation, with a significant focus on decarbonizing industrial processes. Industrial heat generation accounts for approximately half of all global energy consumption and up to 70% of industrial energy use. The transition to renewable energy sources necessitates efficient storage solutions to ensure a stable supply. Thermal Energy Storage (TES) is emerging as a critical technology to address this challenge, directly contributing to several United Nations Sustainable Development Goals (SDGs).

Thermal Energy Storage Technologies and SDG Alignment

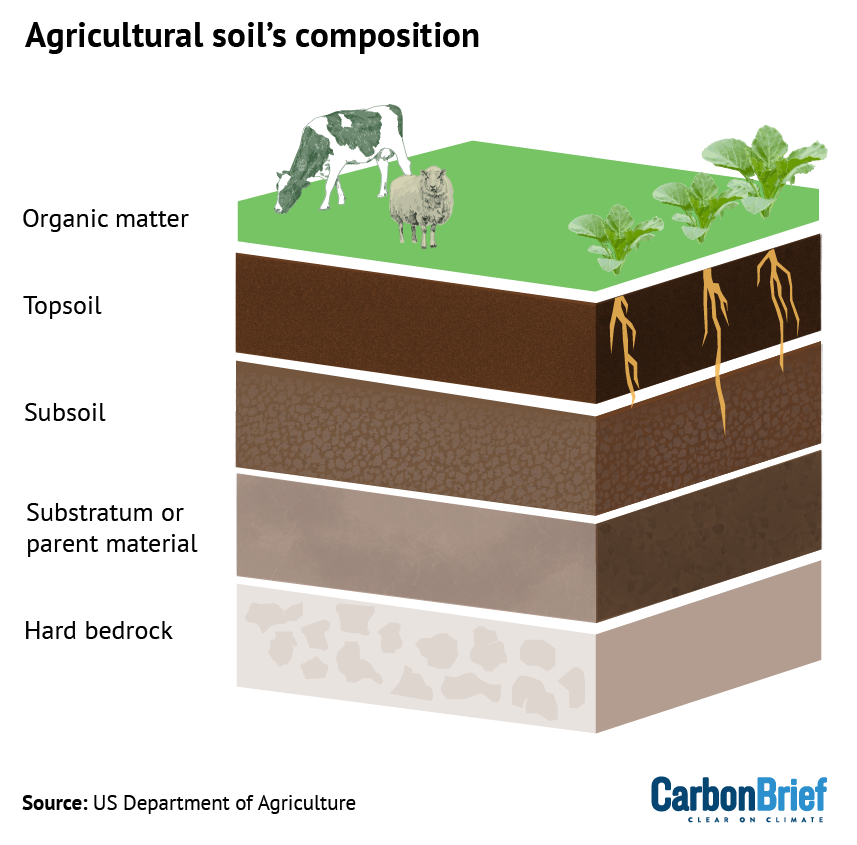

TES systems offer distinct advantages over conventional chemical batteries, including the use of abundant, low-cost raw materials (e.g., concrete, salt, recycled industrial byproducts) and significantly longer operational lifespans. These characteristics align with principles of sustainable and resilient infrastructure. There are three primary approaches to TES.

Sensible Thermal Energy Storage

This is the most established form of TES, where heat is stored by raising the temperature of a solid or liquid medium. This technology directly supports the following SDGs:

- SDG 7 (Affordable and Clean Energy): By storing heat from renewable sources, these systems enable the continuous use of clean energy for industrial processes, reducing reliance on fossil fuels.

- SDG 9 (Industry, Innovation, and Infrastructure): Companies are innovating with legacy materials to create resilient and sustainable industrial infrastructure.

- SDG 12 (Responsible Consumption and Production): The use of recycled materials promotes a circular economy.

Key industry examples include:

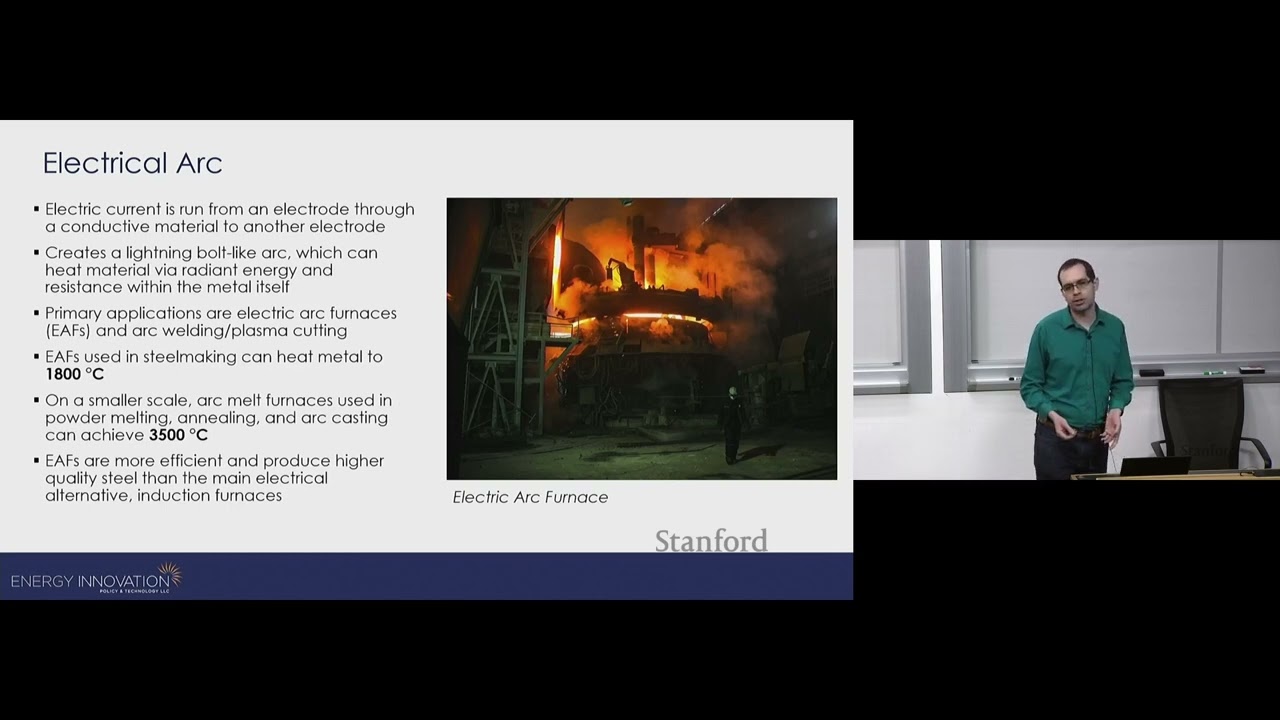

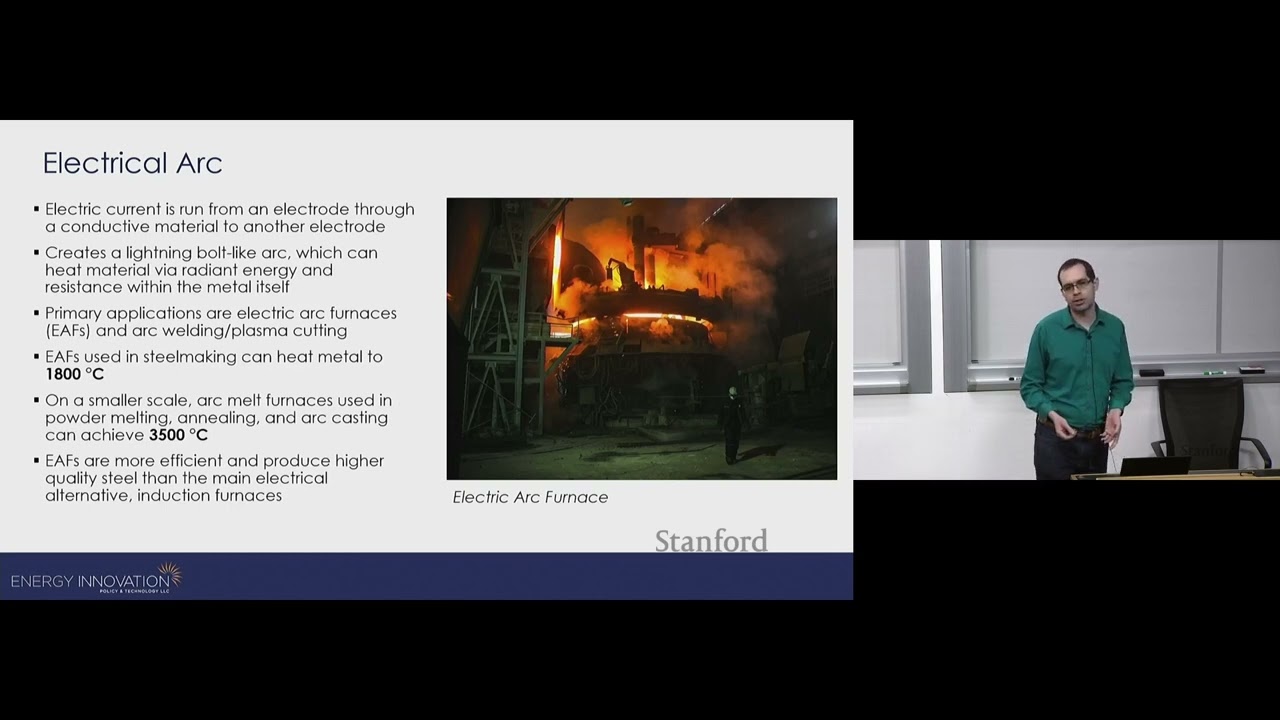

- Rondo: This American company utilizes refractory bricks to store energy at temperatures up to 1,500°C. Its large-scale battery configurations (100-300MWh) are designed to facilitate the decarbonization of heavy industry, advancing SDG 9.

- Kraftblock: This German firm has developed a proprietary storage medium from recycled steel slag, a waste product. This innovation directly supports SDG 12. Its high-density thermal battery, which will replace a natural gas boiler at a PepsiCo facility, exemplifies the practical application of SDG 7 by storing grid-supplied renewable energy for industrial use.

Latent and Thermochemical Energy Storage

These advanced methods store energy through phase changes or reversible chemical reactions, offering high energy densities and potential for transportability.

- Latent Heat Storage: Energy is stored as a material changes phase (e.g., solid to liquid). This technology contributes to:

- SDG 11 (Sustainable Cities and Communities): Systems can be applied in residential settings for applications like water heating, improving energy efficiency in homes.

- SDG 9 (Industry, Innovation, and Infrastructure): Hybrid systems are being developed for industrial-scale applications.

Notable developments include:

- Sunamp: A UK-based firm focusing on residential applications using a modified sodium acetate solution. Its products for water heaters contribute to making communities more sustainable (SDG 11).

- MGA Thermal: An Australian company developing a hybrid system for industrial use where metal alloy chips are embedded in graphite blocks. This innovative approach aims to provide stable, high-temperature heat for industry, supporting SDG 9.

- Thermochemical Storage: This method uses heat to drive a reversible chemical reaction. While still in early development, it promises very high energy density, which could be transformative for transporting clean energy, thereby supporting future advancements under SDG 7 and SDG 9.

Impact on Global Climate and Sustainability Targets

Driving SDG 13: Climate Action

The most significant contribution of TES is its potential to mitigate climate change. According to the International Energy Agency (IEA), industrial heat generation is responsible for approximately 9.4 Gt of CO₂ emissions annually, or one-fifth of the global total. The widespread adoption of TES systems powered by renewable energy could eliminate a substantial portion of this carbon footprint, representing a direct and impactful measure for climate action under SDG 13.

Fostering Sustainable Industrialization and Clean Energy

TES technology is fundamental to achieving a sustainable industrial future. Its role includes:

- Supporting SDG 7 (Affordable and Clean Energy): TES resolves the intermittency of renewable energy sources like solar and wind, making them a viable and reliable power source for heat-intensive industries 24/7.

- Advancing SDG 9 (Industry, Innovation, and Infrastructure): The development and deployment of TES represent a significant innovation in industrial infrastructure, creating systems that are both sustainable and economically competitive.

- Promoting SDG 12 (Responsible Consumption and Production): The use of recycled and abundant materials in TES systems, as demonstrated by Kraftblock, exemplifies sustainable production patterns and the principles of a circular economy.

In conclusion, Thermal Energy Storage is a nascent but essential technology. Its continued development and deployment are critical for decarbonizing the industrial sector and will be instrumental in achieving multiple Sustainable Development Goals as the world transitions to a post-climate age.

SDGs Addressed in the Article

SDG 7: Affordable and Clean Energy

- The article focuses on Thermal Energy Storage (TES) as a solution to store energy from renewables, making clean energy more reliable and accessible for industrial heat, which accounts for about half of all global energy use. It discusses making operations more efficient and switching to renewables.

SDG 9: Industry, Innovation, and Infrastructure

- The text highlights innovation in the industrial sector through the development of new TES technologies by startups like Rondo, Kraftblock, Sunamp, and MGA Thermal. It describes retrofitting industries, such as a PepsiCo facility replacing a natural gas boiler with a thermal battery, to create more sustainable infrastructure.

SDG 12: Responsible Consumption and Production

- The article touches on sustainable production patterns by mentioning the use of “cheap and plentiful” materials like dirt and concrete. Specifically, it notes that the company Kraftblock uses “recycled steel slag—a waste product from blast furnaces,” which promotes a circular economy and reduces waste.

SDG 13: Climate Action

- The core climate impact is addressed directly. The article states that industrial heat emits “approximately 9.4 Gt CO₂ per year” and that TES technology could eliminate a “significant proportion of this carbon footprint,” positioning it as a crucial tool for climate change mitigation.

Specific SDG Targets Identified

Targets for SDG 7: Affordable and Clean Energy

- Target 7.2: Increase substantially the share of renewable energy in the global energy mix. The article supports this by presenting TES as a way to “eliminate intermittency issues” of renewables, thus enabling industrial firms to “switch to renewables to electrify operations.”

- Target 7.3: Double the global rate of improvement in energy efficiency. The article explicitly mentions that converting power to heat or storing heat via TES is “very efficient—in the 95% range.”

Targets for SDG 9: Industry, Innovation, and Infrastructure

- Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies. The article provides a direct example with Kraftblock’s thermal battery replacing a “25MW natural gas boiler” at a PepsiCo manufacturing facility, demonstrating the adoption of a clean technology to make an industrial process sustainable.

Targets for SDG 12: Responsible Consumption and Production

- Target 12.2: Achieve the sustainable management and efficient use of natural resources. The article highlights that TES systems use “cheap and plentiful” raw materials like dirt and concrete, and specifically mentions Kraftblock’s use of recycled steel slag, which is an efficient use of a waste product.

- Target 12.5: Substantially reduce waste generation through prevention, reduction, recycling and reuse. The use of “recycled steel slag—a waste product from blast furnaces” by Kraftblock is a clear example of recycling and reuse to create a new product, thereby reducing industrial waste.

Targets for SDG 13: Climate Action

- Target 13.2: Integrate climate change measures into policies and planning. While not about national policy, the article discusses technologies that enable corporations to integrate climate action into their industrial planning, aiming to eliminate a “significant proportion” of the 9.4 Gt of CO₂ emitted annually from industrial heat.

Indicators for Measuring Progress

Indicators for SDG 7

- Energy Efficiency: The article provides a direct indicator by stating that the efficiency of converting power to heat or storing it in thermal batteries is “in the 95% range.”

- Renewable Energy Share: An implied indicator is the amount of energy capacity from fossil fuels being replaced by clean alternatives. The article mentions the replacement of a “25MW natural gas boiler” and new storage projects totaling “over 200MWh of energy storage.”

Indicators for SDG 9

- CO₂ Emissions from Industry: The article provides a baseline indicator for industrial emissions, stating that “industrial heat alone emits approximately 9.4 Gt CO₂ per year.” Progress can be measured by the reduction of these emissions through the adoption of TES.

- Adoption of Clean Technology: The capacity of new TES installations serves as an indicator of adoption. The article mentions specific configurations, such as Rondo’s batteries with “100MWh of capacity” and “300MWh.”

Indicators for SDG 12

- Use of Recycled Material: A qualitative indicator mentioned is the composition of the storage medium. Kraftblock’s technology uses “recycled steel slag,” indicating progress towards circular economy principles. The amount of waste material repurposed would be a quantitative measure.

Indicators for SDG 13

- Greenhouse Gas Emissions: The primary indicator is the volume of CO₂ emissions. The article quantifies the problem as “9.4 Gt CO₂ per year” from industrial heat, which is “equivalent to around one-fifth of global CO₂ emissions.” The reduction of this figure is the key metric for measuring progress on climate action.

Summary of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 7: Affordable and Clean Energy |

7.2: Increase the share of renewable energy.

7.3: Improve energy efficiency. |

– Energy capacity from fossil fuels replaced by renewables (e.g., a 25MW natural gas boiler). – Energy storage capacity installed (e.g., 200MWh). – Efficiency of energy conversion and storage (stated as “in the 95% range”). |

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries with clean and sustainable technologies. |

– CO₂ emissions from industrial processes (baseline of 9.4 Gt CO₂ per year from industrial heat). – Adoption of clean technologies measured by installed capacity (e.g., 100MWh and 300MWh battery configurations). |

| SDG 12: Responsible Consumption and Production |

12.2: Achieve sustainable management and efficient use of natural resources.

12.5: Substantially reduce waste generation through recycling and reuse. |

– Use of recycled materials in production (e.g., “recycled steel slag”). |

| SDG 13: Climate Action | 13.2: Integrate climate change measures into planning and strategies. |

– Total greenhouse gas emissions from specific sectors (industrial heat accounts for “9.4 Gt CO₂ per year”). – Reduction in CO₂ emissions from the adoption of mitigation technologies. |

Source: forbes.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0