How Smart Technology Closes the Productivity Value Gap in Manufacturing – DirectIndustry e-Magazine

Report on the Industrial “Value Gap” and its Implications for Sustainable Development

A significant performance disparity, termed the “value gap,” is emerging between the most and least productive organizations within the manufacturing sector. This gap is primarily driven by strategic investments in smart technology. An analysis of 500 technology-driven manufacturers reveals that proactive companies investing in future-oriented strategies are achieving sustainable growth and enhancing their contributions to global sustainability targets. This report outlines the key factors driving this disparity and their alignment with the United Nations Sustainable Development Goals (SDGs).

Key Success Factors for Closing the Value Gap and Advancing SDGs

The study identifies four critical areas where leading companies excel. Addressing these areas provides a strategic roadmap for underperforming organizations to enhance productivity and align their operations with key SDGs.

1. Process and System Optimization for Responsible Production (SDG 12)

A notable value gap exists in operational processes, ranging from 21% in productivity-focused functions to 28% in compliance. To address this, organizations must prioritize process optimization, which directly supports SDG 12: Responsible Consumption and Production.

- Automation: Implementing automation across the supply chain is crucial for enhancing efficiency and reducing waste.

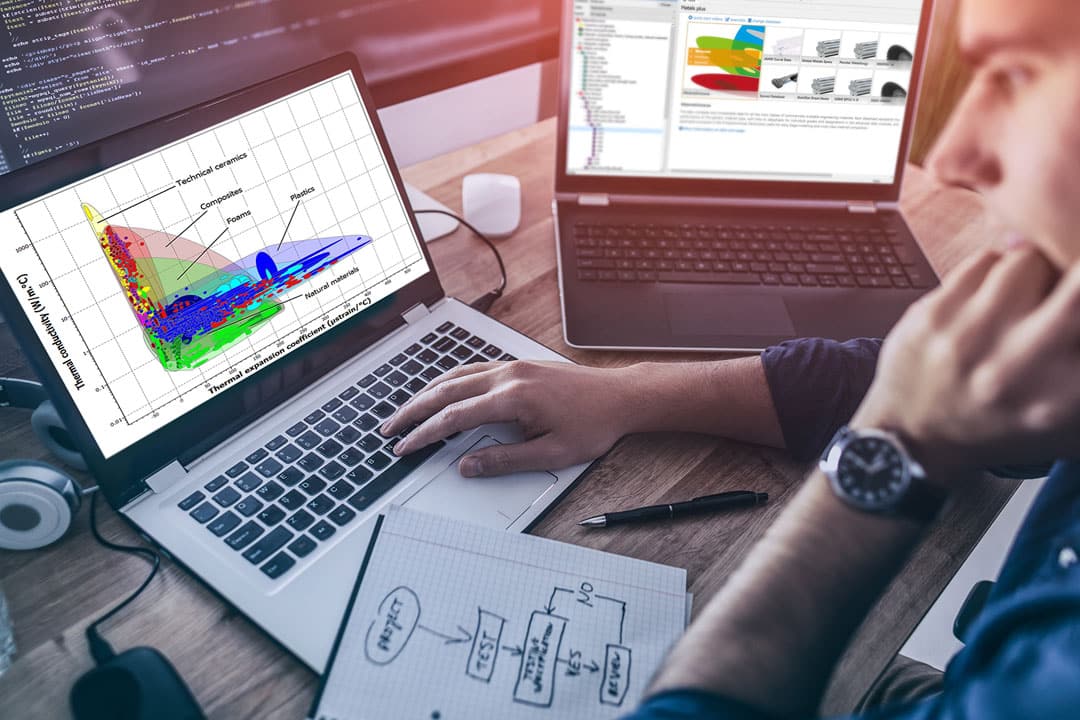

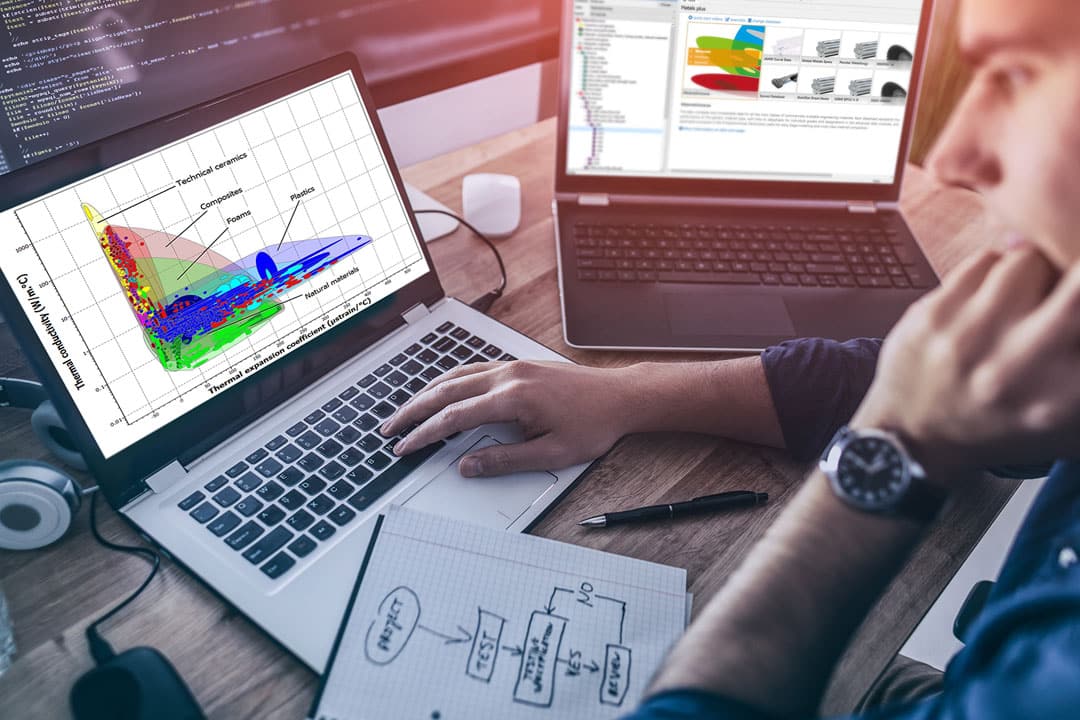

- Process Mining: This technology provides real-time analysis to identify bottlenecks and inefficiencies. By eliminating these, companies can achieve more sustainable production patterns, minimize resource consumption, and ensure that continuous small improvements lead to significant gains in overall sustainability and productivity.

2. Agility and Foresight for Industrial Innovation (SDG 9)

The report identifies a substantial 43% value gap in innovation, indicating that less productive companies are lagging in the use of digital tools. This area is fundamental to achieving SDG 9: Industry, Innovation, and Infrastructure.

- Digital Acceleration: Top-performing companies utilize digital technologies 58% of the time to accelerate innovation, compared to only 14% among lower-performing peers.

- Market Advantage: Accelerating the product-to-market timeline is a key differentiator that enhances market share and customer satisfaction. By investing in digital innovation, companies contribute to building resilient infrastructure and promoting inclusive and sustainable industrialization.

3. A Data-Driven Culture for Sustainable Economic Growth (SDG 8)

Effective data utilization is a hallmark of top-performing companies. The analysis reveals a 42% value gap in the application of data analytics for improving daily operations and product development, highlighting an opportunity to advance SDG 8: Decent Work and Economic Growth.

- Informed Decision-Making: While the gap in using data for demand forecasting is modest (14%), the significant disparity in operational data use shows a major opportunity.

- Productivity as a Growth Driver: By fostering a data-driven culture, companies can significantly boost efficiency and productivity, which are foundational pillars for promoting sustained, inclusive, and sustainable economic growth.

4. Customer-Centricity and Collaborative Innovation (SDG 17)

Leading manufacturers differentiate themselves by focusing on customer success and embedding a culture of innovation, which reflects the collaborative principles of SDG 17: Partnerships for the Goals.

- Innovation Culture Gap: A 32% performance gap is observed in fostering an ingrained culture of innovation. Notably, 50% of the most productive companies address this by establishing dedicated innovation departments.

- Stakeholder Engagement: The continuous use of customer feedback to align products with user needs exemplifies a partnership approach. By embedding smart technology into products to understand customer usage (a smaller gap of 7%), companies can create value through collaboration, driving progress toward shared sustainability objectives.

Conclusion: Digital Transformation as a Pathway to Sustainable Competitiveness

The findings indicate that for manufacturing entities, including those in the French industrial sector, adopting tailored digital technologies is essential for enhancing productivity and creating new value. Leaders must view digital transformation not only as a tool for competitive advantage but as a strategic imperative to close the value gap. By doing so, the industrial sector can significantly advance its contribution to the 2030 Agenda for Sustainable Development, particularly SDGs 8, 9, 12, and 17.

SDGs Addressed in the Article

SDG 9: Industry, Innovation, and Infrastructure

The article is fundamentally centered on SDG 9, as it explores how manufacturing companies can enhance their productivity, competitiveness, and sustainability through technological adoption and innovation. It directly discusses the modernization of the industrial sector, the importance of resilient strategies, and the role of technology in creating value. The text’s focus on “investing in smart technology,” “digital transformation,” and boosting productivity in the “French industrial sector” aligns with the core principles of this goal.

SDG 8: Decent Work and Economic Growth

The article connects to SDG 8 by emphasizing the drive for higher economic productivity as a key to business success. It discusses how closing the “value gap” between companies leads to “boosting profits, company value, and product innovation.” The article’s main argument is that investing in technology and improving processes are crucial for “sustainable growth,” which is a cornerstone of SDG 8. By improving productivity, companies contribute to overall economic growth.

Specific Targets Identified

Targets under SDG 9: Industry, Innovation, and Infrastructure

-

Target 9.4: “By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes…”

- Explanation: The article advocates for manufacturers to “automate their workflows across the entire supply chain” and use “Process Mining” to “pinpoint bottlenecks, inefficiencies, and deviations.” This directly relates to upgrading industrial processes for greater efficiency through the adoption of modern technologies. The article’s call for a “digital transformation programme to stay competitive” is a clear echo of this target.

-

Target 9.5: “Enhance scientific research, upgrade the technological capabilities of industrial sectors in all countries… encouraging innovation…”

- Explanation: The article highlights a significant “43% ‘value gap'” in innovation and notes that “less productive companies are far behind in using digital tools to launch new products.” It further states that top companies foster an “ingrained culture of innovation,” with half of them having a “dedicated innovation department.” This directly addresses the need to upgrade technological capabilities and encourage innovation within industries.

Targets under SDG 8: Decent Work and Economic Growth

-

Target 8.2: “Achieve higher levels of economic productivity through diversification, technological upgrading and innovation…”

- Explanation: The central theme of the article is how to increase productivity. It explicitly asks, “what truly drives it?” and answers by pointing to technology investments and process optimization. The text states that adopting “technologies tailored to unique processes can significantly boost productivity and create new value,” which aligns perfectly with achieving higher economic productivity through technological upgrading and innovation.

Indicators Mentioned or Implied

Indicators for SDG 9 Targets

-

For Target 9.4 (Efficiency and Technology Adoption):

- Implied Indicator: Level of process automation. The article suggests that manufacturers “should automate their workflows across the entire supply chain,” implying that the percentage of automated processes is a key metric for progress.

- Implied Indicator: The “value gap” in compliance and productivity-focused areas. The article quantifies these gaps (“21% difference in productivity-focused areas to 28% in compliance”), which can be used as indicators to measure disparities in industrial efficiency.

-

For Target 9.5 (Innovation):

- Mentioned Indicator: Percentage of companies using digital tools for innovation. The article provides a direct metric: “The best performers use digital technologies 58% of the time to speed up innovation, compared to just 14% for weaker companies.”

- Mentioned Indicator: Presence of a dedicated innovation department. The article states, “Half of the most productive companies tackle this by having a dedicated innovation department,” making it a clear, measurable indicator.

Indicators for SDG 8 Targets

-

For Target 8.2 (Productivity):

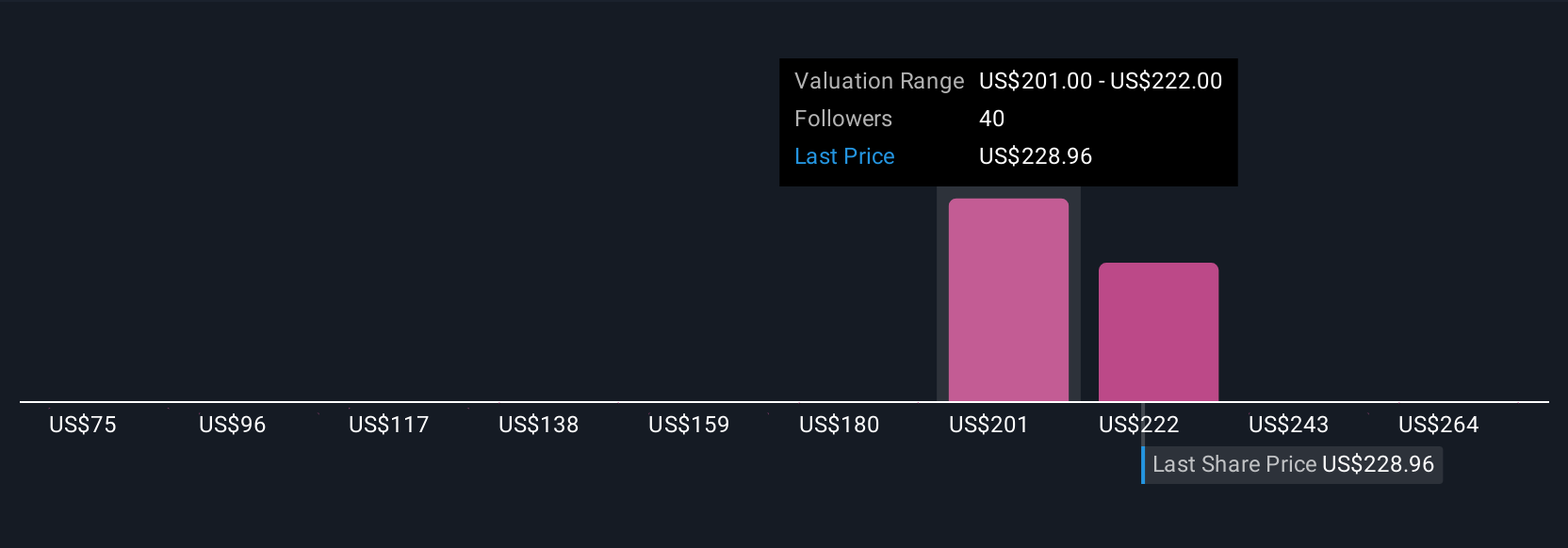

- Implied Indicator: The “value gap” in productivity. The article is built around the concept of the “value gap,” which it defines as “the difference between top and bottom performers.” This gap, quantified in areas like innovation (43%) and data analysis (42%), serves as a direct measure of productivity differences.

- Implied Indicator: Use of data analysis for operational improvement. The article notes a “42% [gap] when data analysis is used to improve everyday tasks.” The extent to which companies use data for decision-making is an implied indicator of technological upgrading for productivity.

SDGs, Targets, and Indicators Analysis

| SDGs | Targets | Indicators (Mentioned or Implied in the Article) |

|---|---|---|

| SDG 9: Industry, Innovation, and Infrastructure | Target 9.4: Upgrade industries for sustainability and efficiency through greater adoption of technology. |

|

| Target 9.5: Enhance research and upgrade technological capabilities to encourage innovation. |

|

|

| SDG 8: Decent Work and Economic Growth | Target 8.2: Achieve higher levels of economic productivity through technological upgrading and innovation. |

|

Source: emag.directindustry.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0