Prototype ultrasonic desalination instrument and its performance test – Nature

Report on the Development and Performance of an Ultrasonic Desalination Instrument for Sea Sand in Alignment with Sustainable Development Goals

Executive Summary

This report details the development and performance evaluation of a large-scale ultrasonic washing instrument for the desalination of sea sand. The research addresses the urgent need for sustainable construction materials, directly contributing to several United Nations Sustainable Development Goals (SDGs), including SDG 9 (Industry, Innovation, and Infrastructure), SDG 11 (Sustainable Cities and Communities), and SDG 12 (Responsible Consumption and Production). Preliminary experiments confirmed the efficacy of ultrasonic power in salt removal. Subsequently, a 1500 W, 25 L capacity prototype was developed and tested. The study identified optimal washing conditions as a 2:1 water-to-sea sand ratio, an ultrasonic intensity of 1200 W, and a minimum washing time of 3 minutes. These conditions successfully reduced salinity to meet construction standards. The findings validate the developed equipment as an efficient, innovative, and environmentally responsible alternative to conventional methods, promoting the use of sea sand as a sustainable aggregate and advancing the goals of building resilient infrastructure and sustainable communities.

1. Introduction: The Need for Sustainable Construction Materials

The global construction industry faces escalating material costs and resource scarcity, hindering progress toward SDG 11, which aims to make cities and human settlements inclusive, safe, resilient, and sustainable. Sea sand presents an abundant and cost-effective alternative to traditional land-extracted sand, but its high salinity poses a significant risk to structural integrity, particularly through the corrosion of reinforcing steel. Current desalination methods, such as long-term stockpiling and water-intensive sprinkler washing, are inefficient and environmentally burdensome, conflicting with the principles of SDG 12. This research addresses this critical gap by developing an innovative technological solution, thereby supporting SDG 9 by fostering innovation for resilient infrastructure.

2. Development of an Innovative Desalination Technology

2.1. Principle of Ultrasonic Washing

Ultrasonic washing technology utilizes high-frequency sound waves to induce cavitation in a liquid medium. This process involves the formation and rapid collapse of microscopic vacuum bubbles, which generate powerful shock waves and high-energy fluid jets. This mechanism offers a highly efficient method for dislodging salt and other contaminants from the surface of sand particles. This innovative approach provides a more sustainable production pattern compared to traditional methods by:

- Increasing energy and water efficiency.

- Reducing the time required for desalination.

- Minimizing the physical footprint needed for processing.

2.2. Prototype Design and Development

Based on successful preliminary experiments with a portable device, a large-scale prototype was designed and constructed. The key specifications of the developed instrument are:

- Maximum Output: 1500 W

- Ultrasonic Frequency: 28 kHz

- Washing Tank Capacity: 25 L

- Mechanism: A screw conveyor system for continuous movement and mixing of sand during ultrasonic exposure.

This design facilitates a controlled and efficient washing process, essential for scaling up the technology for industrial applications in line with SDG 9.

3. Experimental Methodology and Performance Evaluation

3.1. Preliminary Experiments

Initial tests were conducted using a portable ultrasonic cleaner on sea sand samples collected from various locations in Busan, South Korea. The experiments evaluated four conditions to isolate the effects of ultrasonic treatment and mechanical mixing:

- Ultrasonic treatment with mixing (UOMO)

- Mixing only (UXMO)

- Ultrasonic treatment only (UOMX)

- No treatment (UXMX)

Results consistently showed that the combination of ultrasonic treatment and mechanical mixing (UOMO) yielded the highest and fastest increase in water salinity, confirming its superior effectiveness in removing salt from the sand.

3.2. Prototype Performance Testing

Parametric experiments were performed using the developed large-scale prototype to determine the optimal conditions for desalination. The key variables investigated were:

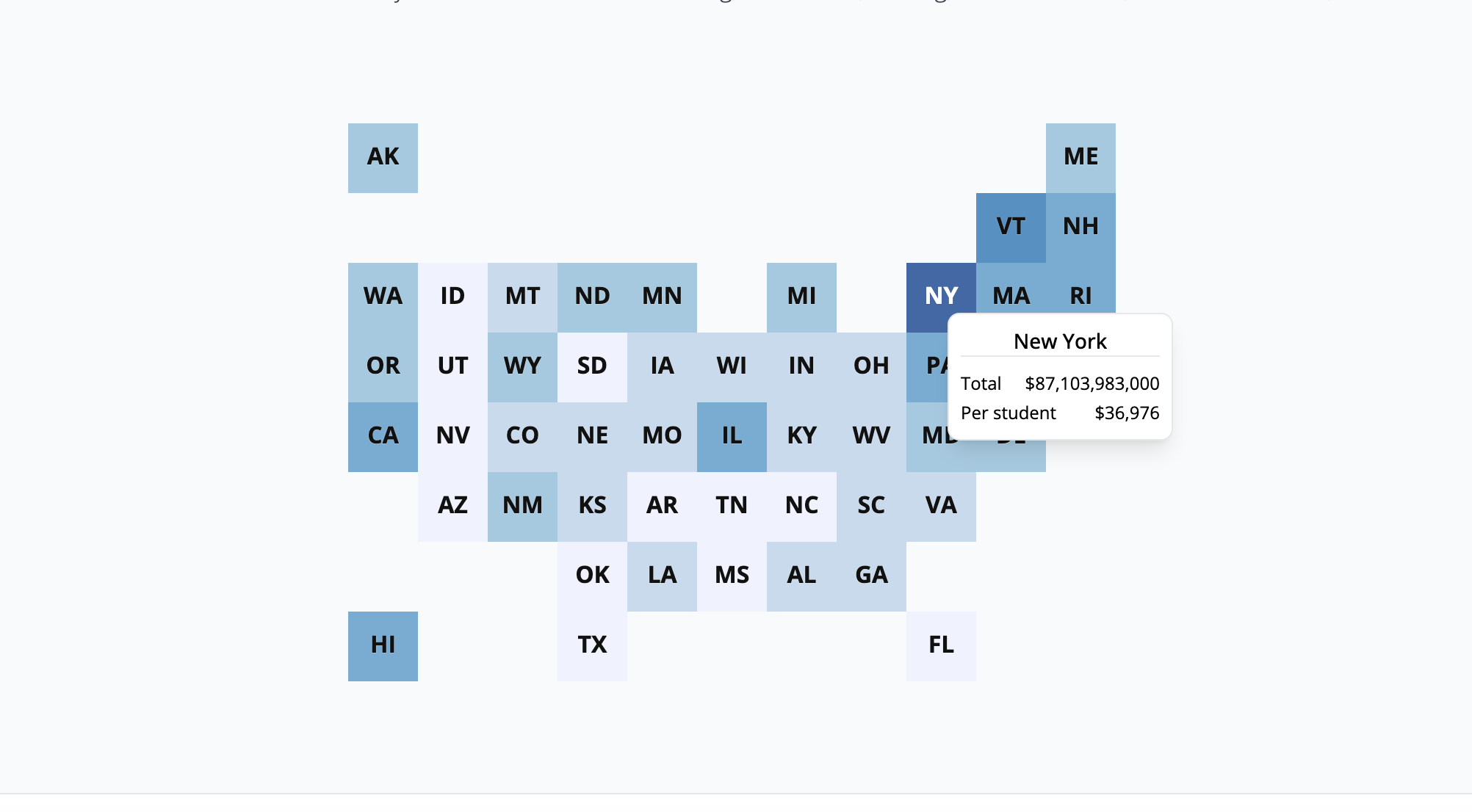

- Washing Water-to-Sea Sand Ratio: 1:1 and 2:1

- Ultrasonic Intensity: 0 W (mixing only), 300 W, 600 W, and 1200 W

- Washing Time: 2 minutes and 3 minutes

The salinity of the washed sand was measured after a standardized drying and preparation process to evaluate the effectiveness of each combination of parameters.

4. Results and Discussion: Achieving Sustainable Desalination

4.1. Impact of Operational Parameters

The experimental results demonstrated that all three variables significantly influenced washing efficiency. The most critical factor was the water-to-sand ratio. A ratio of 2:1 ensured thorough mixing and allowed ultrasonic waves to interact effectively with the sand particles, leading to substantially better performance than the 1:1 ratio, where poor mixing hindered the process.

4.2. Optimal Washing Conditions

The study concluded that the optimal conditions for achieving the required salinity level for construction aggregate (below the Korean standard of 0.04%) were:

- Ultrasonic Intensity: 1200 W

- Water-to-Sea Sand Ratio: 2:1

- Washing Time: A minimum of 3 minutes

Under these conditions, the equipment successfully reduced the initial average salinity of 0.246% to levels compliant with industry standards. This efficiency represents a significant advancement over conventional methods, which can take months or require vast amounts of water, thereby promoting the goals of SDG 12.

5. Conclusion and Contribution to Sustainable Development Goals

This study successfully developed and validated a prototype ultrasonic washing instrument for the desalination of sea sand. The research confirms that a combination of ultrasonic intensity, adequate washing time, and a proper water-to-sand ratio can effectively and efficiently reduce sea sand salinity to meet construction standards.

The applicability of this technology directly supports several SDGs:

- SDG 9 (Industry, Innovation, and Infrastructure): The developed instrument is an innovative technological solution that enhances the quality and sustainability of materials used for building resilient infrastructure.

- SDG 11 (Sustainable Cities and Communities): By enabling the use of abundant and cost-effective sea sand, this technology can help lower construction costs, making infrastructure and housing more affordable and accessible.

- SDG 12 (Responsible Consumption and Production): The ultrasonic washing process is significantly more efficient in terms of time, water, and land use compared to traditional methods, promoting sustainable production patterns in the construction industry.

- SDG 14 (Life Below Water): The technology provides a viable method for utilizing dredged sea sand, turning a byproduct of waterway maintenance into a valuable resource and contributing to a more circular economy for marine resources.

Future work will focus on refining the equipment’s mixing mechanism and scaling the system for high-capacity, industrial-level applications. The optimal conditions identified in this report provide a strong foundation for the commercialization of this sustainable technology.

Analysis of Sustainable Development Goals (SDGs) in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

The article on the development of an ultrasonic desalination instrument for sea sand connects to several Sustainable Development Goals by addressing issues of industrial innovation, sustainable resource management, water efficiency, and building resilient infrastructure.

-

SDG 9: Industry, Innovation and Infrastructure

The core of the article is the development and testing of an innovative technology—a “large-scale ultrasonic washing instrument”—to improve an industrial process (desalination of sea sand). This directly supports building resilient infrastructure by providing a cost-effective, alternative construction material and promoting clean, environmentally sound technologies.

-

SDG 12: Responsible Consumption and Production

The article promotes the use of sea sand as a “cost-effective substitute for traditional land-extracted sand,” which aligns with the sustainable and efficient use of natural resources. It also discusses using sand from dredging, which turns a potential waste product from maintaining navigation channels into a valuable resource, contributing to waste reduction.

-

SDG 6: Clean Water and Sanitation

The research highlights the inefficiency of conventional sand washing methods, noting that “sprinkler washing… requires large amounts of water.” The newly developed ultrasonic method is presented as a more efficient alternative that “significantly reduces water consumption,” thereby increasing water-use efficiency in an industrial sector.

-

SDG 11: Sustainable Cities and Communities

By developing a method to make sea sand a viable and “cost-effective” material for “large-scale infrastructure and residential construction,” the technology contributes to making construction more affordable and sustainable. This supports the goal of building safe, resilient, and sustainable cities and human settlements.

-

SDG 14: Life Below Water

The article addresses the management of a marine resource (sea sand). By developing a more efficient and less wasteful washing technology, it implicitly supports the reduction of land-based pollution. The traditional “sprinkler washing” method requires “additional pollution control measures,” suggesting the new technology has a smaller environmental footprint, which is crucial for protecting marine and coastal ecosystems.

2. What specific targets under those SDGs can be identified based on the article’s content?

The article’s content aligns with several specific targets within the identified SDGs.

-

SDG 9: Industry, Innovation and Infrastructure

- Target 9.4: “By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes…”

Explanation: The development of the ultrasonic washing instrument is a direct attempt to create a “clean and environmentally sound technology” that increases “resource-use efficiency” by making sea sand usable for construction, thus upgrading an industrial process. - Target 9.5: “Enhance scientific research, upgrade the technological capabilities of industrial sectors…”

Explanation: The entire study is a form of scientific research aimed at developing and optimizing a new technology (“a large-scale ultrasonic washing system was developed”) to solve a problem in the construction industry.

- Target 9.4: “By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes…”

-

SDG 12: Responsible Consumption and Production

- Target 12.2: “By 2030, achieve the sustainable management and efficient use of natural resources.”

Explanation: The article focuses on the “utilization of sea sand” as an “abundant supply” to substitute for “traditional land-extracted sand,” which is a clear example of promoting the efficient use of a natural resource. - Target 12.5: “By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.”

Explanation: The article suggests that the technology can be applied to “sea sand already accumulated in dredging landfills,” effectively reusing a material that might otherwise be considered waste from dredging operations.

- Target 12.2: “By 2030, achieve the sustainable management and efficient use of natural resources.”

-

SDG 6: Clean Water and Sanitation

- Target 6.4: “By 2030, substantially increase water-use efficiency across all sectors…”

Explanation: The article explicitly contrasts the new technology with the conventional “water sprinkling method,” which involves “excessive water consumption.” The ultrasonic method “significantly reduces water consumption,” directly addressing the goal of increasing water-use efficiency.

- Target 6.4: “By 2030, substantially increase water-use efficiency across all sectors…”

-

SDG 11: Sustainable Cities and Communities

- Target 11.c: “Support… building sustainable and resilient buildings utilizing local materials.”

Explanation: The technology enables the use of sea sand, an abundant local material in coastal regions, for construction. This promotes resourcefulness and sustainability in building practices, as highlighted by its use in countries like Japan, China, and South Korea.

- Target 11.c: “Support… building sustainable and resilient buildings utilizing local materials.”

-

SDG 14: Life Below Water

- Target 14.2: “By 2020, sustainably manage and protect marine and coastal ecosystems to avoid significant adverse impacts…”

Explanation: The article’s focus on improving desalination methods helps minimize the land-based impacts of processing marine resources. The new technology is described as superior in “environmental sustainability” compared to traditional methods that require “leachate control facilities” and “a separate purification system for treating the wastewater.”

- Target 14.2: “By 2020, sustainably manage and protect marine and coastal ecosystems to avoid significant adverse impacts…”

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

The article provides several quantitative and qualitative indicators that can measure progress towards the identified targets.

-

Indicators for SDG 9 (Targets 9.4 & 9.5)

- Technological Development: The creation and successful performance evaluation of the “prototype sea sand washing equipment” with a “maximum output of 1500 W” and a “25 L capacity.”

- Process Efficiency Metrics: The identification of optimal operating conditions, such as “an ultrasonic intensity of 1200 W,” a “washing water-to-sea sand ratio of 2:1,” and a “minimum washing time of 3 min.”

-

Indicators for SDG 12 (Targets 12.2 & 12.5)

- Resource Substitution Rate: The statistic that “up to 35% to 40% of the total concrete produced in China incorporates sea sand” serves as an indicator of the large-scale substitution of one natural resource for another.

- Waste Valorization: The proposal to use the technology to wash “sea sand already accumulated in dredging landfills,” turning dredged soil into a usable aggregate.

-

Indicators for SDG 6 (Target 6.4)

- Water Consumption Ratio: The optimal “washing water-to-sea sand ratio of 2:1” is a specific indicator of water use for the new technology.

- Comparative Water Use: The statement that the traditional sprinkling method requires “approximately 1.5 tons of water per square meter,” which can be compared against the reduced consumption of the new method.

-

Indicators for SDG 11 (Target 11.c)

- Material Cost Reduction: The description of sea sand as offering “notable economic advantages because of its lower cost,” which makes construction more affordable.

-

Indicators for SDG 14 (Target 14.2)

- Pollution Level Reduction: The ability of the technology to reduce the salinity of sea sand to “below the Korean standard of 0.04%,” which is a direct measure of contaminant removal.

- Reduced Need for Pollution Control: The new method’s advantage over traditional techniques that require “additional pollution control measures” and “wastewater” treatment systems, indicating a lower environmental burden.

4. Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 9: Industry, Innovation and Infrastructure |

9.4: Upgrade infrastructure and industries to make them sustainable and resource-efficient with clean technologies.

9.5: Enhance scientific research and upgrade technological capabilities of industrial sectors. |

– Development of a prototype ultrasonic washing instrument (1500 W output, 25 L capacity). – Identification of optimal process parameters (1200 W intensity, 2:1 water-to-sand ratio, 3-minute washing time). – The research study itself as an enhancement of scientific knowledge for industrial application. |

| SDG 12: Responsible Consumption and Production |

12.2: Achieve the sustainable management and efficient use of natural resources.

12.5: Substantially reduce waste generation through reuse. |

– Use of sea sand as a substitute for land-extracted sand. – Statistic: 35-40% of concrete in China uses sea sand. – Proposal to reuse sand from “dredging landfills,” turning waste into a resource. |

| SDG 6: Clean Water and Sanitation | 6.4: Substantially increase water-use efficiency across all sectors. |

– The optimal “washing water-to-sea sand ratio of 2:1” for the new technology. – Comparison with the traditional method’s high water use (“1.5 tons of water per square meter”). – Statement that the new method “significantly reduces water consumption.” |

| SDG 11: Sustainable Cities and Communities | 11.c: Support building sustainable and resilient buildings utilizing local materials. |

– Use of sea sand, an abundant local material in coastal areas, for construction. – Description of sea sand as a “cost-effective” material with “lower cost,” contributing to affordable construction. |

| SDG 14: Life Below Water | 14.2: Sustainably manage and protect marine and coastal ecosystems to avoid significant adverse impacts. |

– Reduction of salinity to meet the Korean standard of 0.04%. – Reduced need for “additional pollution control measures” and “wastewater” treatment compared to traditional methods. – Superior “environmental sustainability” of the new technology. |

Source: nature.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0