Bioforcetech achieves major breakthrough in PFAS removal – Innovation News Network

Report on Bioforcetech’s Pyrolysis System for PFAS Remediation and its Contribution to Sustainable Development Goals

Executive Summary: Technological Milestone in Environmental Protection

A comprehensive, independent study has validated the high efficiency of Bioforcetech’s Sigma Pyrolysis system in eliminating per- and polyfluoroalkyl substances (PFAS). The technology demonstrates a 99.98% removal rate across all waste streams, including biosolids, discharge water, and exhaust gases. This achievement represents a significant advancement in environmental technology, directly supporting several United Nations Sustainable Development Goals (SDGs).

Alignment with Key Sustainable Development Goals (SDGs)

The successful implementation of this technology provides a direct pathway to achieving critical global sustainability targets. Its impact is most significant in the following areas:

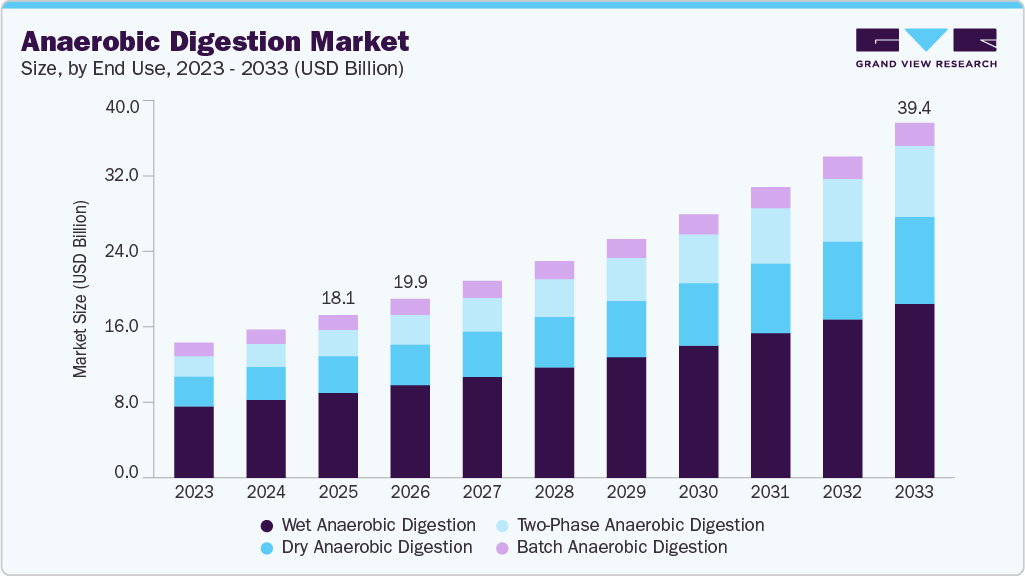

- SDG 6: Clean Water and Sanitation: By effectively destroying PFAS in wastewater biosolids and discharge, the system prevents these persistent chemicals from contaminating ground and surface water sources, ensuring safer water for communities.

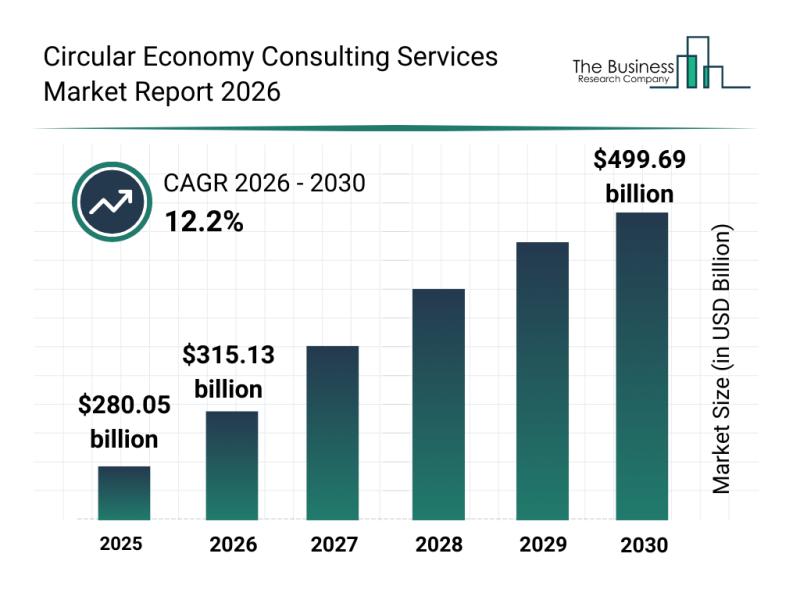

- SDG 12: Responsible Consumption and Production: The process exemplifies circular economy principles by converting hazardous waste into a valuable, safe, and usable product (OurCarbon®), promoting sustainable production patterns.

- SDG 9: Industry, Innovation, and Infrastructure: This technology represents a critical innovation for wastewater management infrastructure, offering a sustainable and resilient solution to a pressing environmental challenge.

- SDG 11: Sustainable Cities and Communities: By providing municipalities with a viable method to manage contaminated biosolids, the system helps create safer, more resilient, and sustainable urban environments.

Technical Validation and Performance Analysis

A rigorous study conducted by Brown and Caldwell confirmed the system’s near-complete destruction of PFAS compounds. The validation process involved a multi-stage analysis with precise methodologies.

- Comprehensive Sampling: Samples were collected from eight distinct points throughout the Bioforcetech process to ensure a complete mass balance analysis.

- Identification of Destruction Point: Results identified the thermal oxidizer, positioned before the exhaust scrubbing stage, as the primary component for PFAS destruction, validating the system’s optimized design.

- Advanced Analytical Methods: A suite of advanced testing protocols was employed to ensure accuracy across different media:

- EPA 1633A for solid materials (biosolids and OurCarbon®).

- OTM 45 for exhaust gases.

- High-sensitivity testing for water, in partnership with North Carolina State University.

- Confirmed Efficacy: The combined results confirmed that only 0.02% of the initial PFAS compounds remain anywhere in the system’s outputs, establishing a new benchmark for PFAS removal technology.

Advancing SDG 12: From Waste Treatment to Resource Creation

A core achievement of the Bioforcetech system is its contribution to a circular economy, a central tenet of SDG 12. The pyrolysis process transforms treated biosolids into OurCarbon®, a sustainable, value-added carbon material. Testing has verified that this end-product is completely free of the PFAS compounds originally present in the input biosolids. This dual-benefit approach—eliminating a harmful pollutant while creating a reusable resource—positions the technology as a leading solution for environmentally responsible waste management.

As stated by Dario Presezzi, CEO of Bioforcetech, “The results from this testing give Bioforcetech even further confidence in our thermal process to alleviate wastewater plants of their biosolids burden and produce a value-added output product.”

Conclusion: A New Standard for Sustainable Wastewater Management

Bioforcetech’s validated success in PFAS removal sets a new standard for managing contaminated waste streams. The technology offers a scalable and effective solution for municipalities and industrial facilities, directly supporting the achievement of SDGs related to clean water (SDG 6), sustainable production (SDG 12), and resilient infrastructure (SDG 9 & 11). By integrating high-efficiency thermal treatment with sustainable resource creation, this innovation paves the way for a safer, more circular approach to environmental management.

Analysis of the Article in Relation to Sustainable Development Goals

1. Which SDGs are addressed or connected to the issues highlighted in the article?

- SDG 6: Clean Water and Sanitation: The article’s primary focus is on a technology that removes PFAS contaminants from wastewater streams (biosolids, discharge water), directly contributing to improving water quality and ensuring safe water management.

- SDG 9: Industry, Innovation, and Infrastructure: The article showcases an advanced, environmentally sound technology (Sigma Pyrolysis) developed by a company (Bioforcetech). This represents an industrial innovation aimed at upgrading infrastructure for sustainable waste management.

- SDG 11: Sustainable Cities and Communities: The technology provides a solution for municipalities to manage their waste (biosolids) more effectively, reducing the environmental impact of cities by preventing the release of harmful PFAS chemicals into the air and water.

- SDG 12: Responsible Consumption and Production: The process described promotes a circular economy model. It achieves the environmentally sound management of chemical waste (PFAS) and transforms biosolids waste into a valuable, reusable product (OurCarbon®), thereby reducing waste generation.

2. What specific targets under those SDGs can be identified based on the article’s content?

- SDG 6: Clean Water and Sanitation

- Target 6.3: By 2030, improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials. The article directly addresses this by describing a technology that eliminates 99.98% of PFAS, a hazardous chemical group, from wastewater streams, thus preventing their release and improving water quality.

- SDG 9: Industry, Innovation, and Infrastructure

- Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable… and greater adoption of clean and environmentally sound technologies and industrial processes. Bioforcetech’s pyrolysis system is a clear example of a clean and environmentally sound technology designed to be adopted by wastewater treatment facilities to manage waste sustainably.

- SDG 11: Sustainable Cities and Communities

- Target 11.6: By 2030, reduce the adverse per capita environmental impact of cities, including by paying special attention to air quality and municipal and other waste management. The technology offers a solution for the management of municipal biosolids and destroys PFAS in exhaust gases, directly addressing both waste management and air quality challenges for cities.

- SDG 12: Responsible Consumption and Production

- Target 12.4: Achieve the environmentally sound management of chemicals and all wastes throughout their life cycle… and significantly reduce their release to air, water and soil. The article details a process for the sound management and near-complete destruction of PFAS chemicals and biosolids waste, preventing their release into the environment.

- Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse. The technology contributes to this target by converting waste biosolids into a “value-added output product” called OurCarbon®, promoting reuse and a circular approach to waste.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

- For SDG 6 (Target 6.3)

- Implied Indicator (related to 6.3.1 – Proportion of wastewater safely treated): The article provides a direct performance metric: the elimination of 99.98% of PFAS compounds. This percentage serves as a powerful indicator of the effectiveness and safety of the wastewater treatment process.

- For SDG 11 (Target 11.6)

- Implied Indicator (related to 11.6.1 – Proportion of municipal solid waste managed in controlled facilities): The article describes a specific, controlled technological process (pyrolysis) for managing a component of municipal waste (biosolids), implying progress in advanced waste management capabilities.

- For SDG 12 (Targets 12.4 and 12.5)

- Implied Indicator (related to 12.4.2 – Proportion of hazardous waste treated): The 99.98% destruction rate of PFAS is a direct measure of the proportion of this hazardous waste that is successfully treated and eliminated.

- Implied Indicator (related to 12.5.1 – National recycling rate, tons of material recycled): The creation of the value-added product “OurCarbon®” from treated biosolids is a form of material recycling/reuse. The amount of OurCarbon® produced would be a direct indicator of progress in turning waste into a resource.

4. Create a table with three columns titled ‘SDGs, Targets and Indicators” to present the findings from analyzing the article.

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 6: Clean Water and Sanitation | 6.3: Improve water quality by reducing pollution and minimizing the release of hazardous chemicals. | The specific removal rate of 99.98% of PFAS from water streams, indicating the proportion of wastewater safely treated. |

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade infrastructure and adopt clean and environmentally sound technologies. | The development and validation of the Sigma Pyrolysis system as an innovative and clean technology for industrial application. |

| SDG 11: Sustainable Cities and Communities | 11.6: Reduce the adverse environmental impact of cities, focusing on air quality and waste management. | The technology’s ability to manage municipal biosolids and destroy PFAS in exhaust gases, improving urban waste and air quality management. |

| SDG 12: Responsible Consumption and Production | 12.4: Achieve environmentally sound management of chemicals and all wastes. | The 99.98% destruction rate serves as a measure for the proportion of hazardous waste (PFAS) effectively treated. |

| SDG 12: Responsible Consumption and Production | 12.5: Substantially reduce waste generation through recycling and reuse. | The conversion of waste biosolids into a reusable, value-added product (OurCarbon®), indicating progress in material recycling. |

Source: innovationnewsnetwork.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

;Resize=620#)