Technologies and gaps in deep decarbonization of hard-to-abate industrial sectors – Nature

Report on Technologies and Gaps in Deep Decarbonization of Hard-to-Abate Industrial Sectors

Introduction

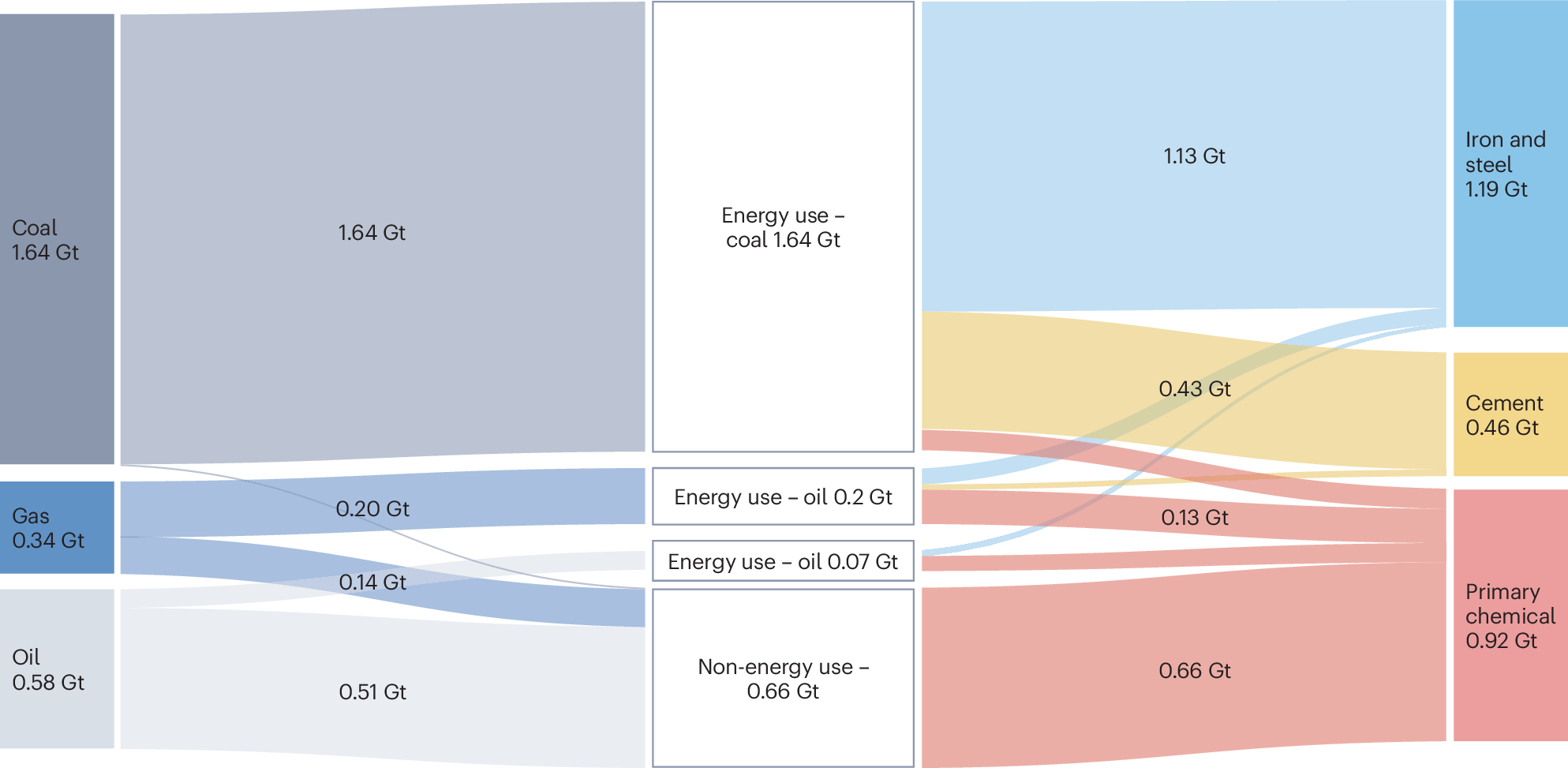

The iron and steel, cement, and primary chemical sectors are significant contributors to global carbon emissions, accounting for approximately 17% of total emissions in 2021. These sectors face considerable challenges in decarbonization due to complex production processes, heavy reliance on fossil fuels, and limited availability of alternative technologies. This report emphasizes the alignment of decarbonization efforts with the United Nations Sustainable Development Goals (SDGs), particularly SDG 7 (Affordable and Clean Energy), SDG 9 (Industry, Innovation and Infrastructure), and SDG 13 (Climate Action).

Current Emissions and Challenges

- Emissions in 2021 were estimated at 2.7 Gt CO2 for iron and steel, 2.5 Gt CO2 for cement, and 0.9 Gt CO2 for primary chemicals.

- These sectors are categorized as hard-to-abate due to their high energy intensity and reliance on fossil fuels.

- Technological readiness varies widely among decarbonization approaches, with some technologies commercially available and others still in nascent stages.

Decarbonization Strategies and Technologies

Decarbonization strategies are grouped into several categories, each contributing to the achievement of SDGs by promoting sustainable industrial development and climate action:

- Energy Efficiency Improvements

- Cost-effective and readily deployable, these improvements reduce energy consumption and emissions.

- Abatement costs range from -$10 to $80 per tonne of CO2 avoided.

- Supports SDG 7 and SDG 9 by enhancing sustainable industrial processes.

- Electrification

- Transitioning to electric-based processes powered by clean energy sources.

- Abatement costs vary between $2 and $201 per tonne of CO2.

- Advances SDG 7 by promoting clean energy use and SDG 13 through emission reductions.

- Recycling and Demand-Side Technologies

- Enhances material circularity, reducing raw material demand and emissions.

- Contributes to SDG 12 (Responsible Consumption and Production) and SDG 13.

- Bioenergy

- Utilizes biomass as a renewable energy source, with abatement costs from $23 to $904 per tonne of CO2.

- Supports SDG 7 and SDG 15 (Life on Land) by promoting sustainable biomass use.

- Carbon Capture and Storage (CCS)

- Captures CO2 emissions for storage or utilization, with costs between $10 and $90 per tonne of CO2.

- Technological readiness ranges from mid to high levels, requiring substantial investment.

- Key to achieving SDG 13 by mitigating industrial emissions.

- Hydrogen Usage

- Incorporates clean hydrogen as fuel or feedstock, with abatement costs of $100 to $1,000 per tonne of CO2.

- Green hydrogen production aligns with SDG 7 and SDG 13.

- Feedstock Substitution

- Replacing fossil-based raw materials with low-carbon alternatives.

- Supports SDG 9 and SDG 12 by fostering sustainable industrial inputs.

Technological Readiness and Economic Considerations

- Some technologies, such as scrap-based electric arc furnace steelmaking, are commercially mature and exhibit green premiums below 20%.

- Emerging technologies like CCS and hydrogen-based approaches have higher green premiums, often exceeding 50%, reflecting current cost and deployment challenges.

- Abatement costs vary significantly across technologies and sectors, influencing feasibility and adoption rates.

- Investment prioritization should focus on readily available technologies in the short term, while supporting innovation and scaling of advanced solutions for long-term impact.

Recommendations for Sustainable Development

- Short-Term Priorities

- Implement energy efficiency improvements, recycling, and electrification to achieve immediate emission reductions.

- Leverage existing technologies to support SDG 7 and SDG 13.

- Long-Term Strategies

- Invest in carbon capture and storage infrastructure and clean hydrogen production to enable deep decarbonization.

- Address resource availability and economic challenges to ensure sustainable technology deployment.

- Promote innovation aligned with SDG 9 to foster resilient and sustainable industrial infrastructure.

- Policy and Collaboration

- Encourage international cooperation and policy frameworks that support technology adoption and green financing.

- Facilitate knowledge sharing and capacity building to accelerate progress towards SDG 13.

Conclusion

The decarbonization of hard-to-abate industrial sectors is critical for meeting global climate targets and advancing the Sustainable Development Goals. A balanced approach that combines immediate deployment of mature technologies with strategic investment in emerging solutions will be essential. Addressing economic, technological, and resource challenges through coordinated efforts can enable a sustainable transition, fostering innovation, clean energy use, and climate resilience in line with the SDGs.

1. Sustainable Development Goals (SDGs) Addressed or Connected

- SDG 7: Affordable and Clean Energy

- The article discusses electrification, bioenergy, hydrogen usage, and energy efficiency improvements in industrial sectors, which are directly related to clean and affordable energy.

- SDG 9: Industry, Innovation and Infrastructure

- Focus on technology opportunities, readiness, and innovation in decarbonizing hard-to-abate industrial sectors such as iron and steel, cement, and chemicals.

- SDG 12: Responsible Consumption and Production

- Emphasis on recycling, demand-side technologies, and feedstock substitution to reduce emissions and promote sustainable industrial processes.

- SDG 13: Climate Action

- The core of the article is about reducing carbon emissions (~17% globally in 2021) through deep decarbonization strategies and technologies.

2. Specific Targets Under the Identified SDGs

- SDG 7: Affordable and Clean Energy

- Target 7.2: Increase substantially the share of renewable energy in the global energy mix.

- Target 7.3: Double the global rate of improvement in energy efficiency.

- SDG 9: Industry, Innovation and Infrastructure

- Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes.

- SDG 12: Responsible Consumption and Production

- Target 12.5: Substantially reduce waste generation through prevention, reduction, recycling, and reuse.

- Target 12.6: Encourage companies to adopt sustainable practices and to integrate sustainability information into their reporting cycle.

- SDG 13: Climate Action

- Target 13.2: Integrate climate change measures into national policies, strategies, and planning.

- Target 13.3: Improve education, awareness-raising, and human and institutional capacity on climate change mitigation, adaptation, impact reduction, and early warning.

3. Indicators Mentioned or Implied to Measure Progress

- Carbon Emissions Metrics

- CO2 emissions from iron and steel (2.7 Gt), cement (2.5 Gt), and primary chemical sectors (0.9 Gt) in 2021 are quantified, implying the use of emission volume as an indicator.

- Emission intensities at plant-level, as shown in figures referenced, suggest measurement of emissions per unit of production.

- Technology Readiness Levels (TRL)

- Readiness of decarbonization technologies (e.g., electric arc furnace, carbon capture and storage, hydrogen-based approaches) is assessed, indicating TRL as an indicator for deployment feasibility.

- Abatement Costs and Green Premiums

- Mitigation cost per tonne of CO2 abated (e.g., US$2–201 for electrification) and green premiums (cost difference between low-carbon and conventional technologies) are used as economic indicators of technology adoption.

- Energy Efficiency Improvements

- Energy efficiency improvements are prioritized, implying measurement of energy consumption per unit output as an indicator.

- Recycling and Demand-Side Technology Uptake

- Extent of recycling and demand-side technology deployment can be used as indicators for responsible production and consumption.

4. Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 7: Affordable and Clean Energy |

|

|

| SDG 9: Industry, Innovation and Infrastructure |

|

|

| SDG 12: Responsible Consumption and Production |

|

|

| SDG 13: Climate Action |

|

|

Source: nature.com