Advancing wind energy design: lessons from NREL’s MADE3D project – 3D Printing Industry

Report on the MADE3D Project: Advancing Sustainable Wind Energy through Additive Manufacturing

Project Overview and Alignment with Sustainable Development Goals

The U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) has concluded the five-year Manufacturing and Additive Design of Electric Machines by 3D Printing (MADE3D) project. This initiative was established to advance wind turbine generator technology through additive manufacturing, directly supporting several United Nations Sustainable Development Goals (SDGs).

Core Objectives and SDG Contributions

- SDG 7 (Affordable and Clean Energy): To enhance the performance, scalability, and cost-effectiveness of next-generation wind energy systems.

- SDG 9 (Industry, Innovation, and Infrastructure): To pioneer innovative manufacturing technologies (3D printing) and design workflows (machine learning) for resilient energy infrastructure.

- SDG 12 (Responsible Consumption and Production): To reduce dependency on critical rare-earth materials and minimize material waste in generator production.

- SDG 17 (Partnerships for the Goals): The project was executed through a multi-stakeholder partnership involving NREL, Oak Ridge National Laboratory (ORNL), NASA Glenn Research Center, and industry partner Bergey WindPower, under the funding of the DOE’s Wind Energy Technologies Office.

Technical Innovations and Contributions to Sustainable Production

Material Efficiency and Resource Management (SDG 12)

A primary focus of the project was to create more sustainable production patterns for wind turbine generators. Research efforts yielded significant material reductions compared to conventional designs:

- A weight reduction of up to 35% in magnets.

- A weight reduction of up to 20% in electrical steel.

- Development of polymer-bonded permanent magnets, reducing the need for traditionally sourced rare-earth elements.

Advanced Design and Manufacturing Processes (SDG 9)

The project introduced several technological innovations to build sustainable industrial capacity.

- Machine Learning for Optimized Design: The MADE3D-AML tool, a machine learning-based surrogate model, was developed for topology optimization. This accelerated generator design workflows, enabling rapid evaluation of configurations to maximize performance while minimizing mass.

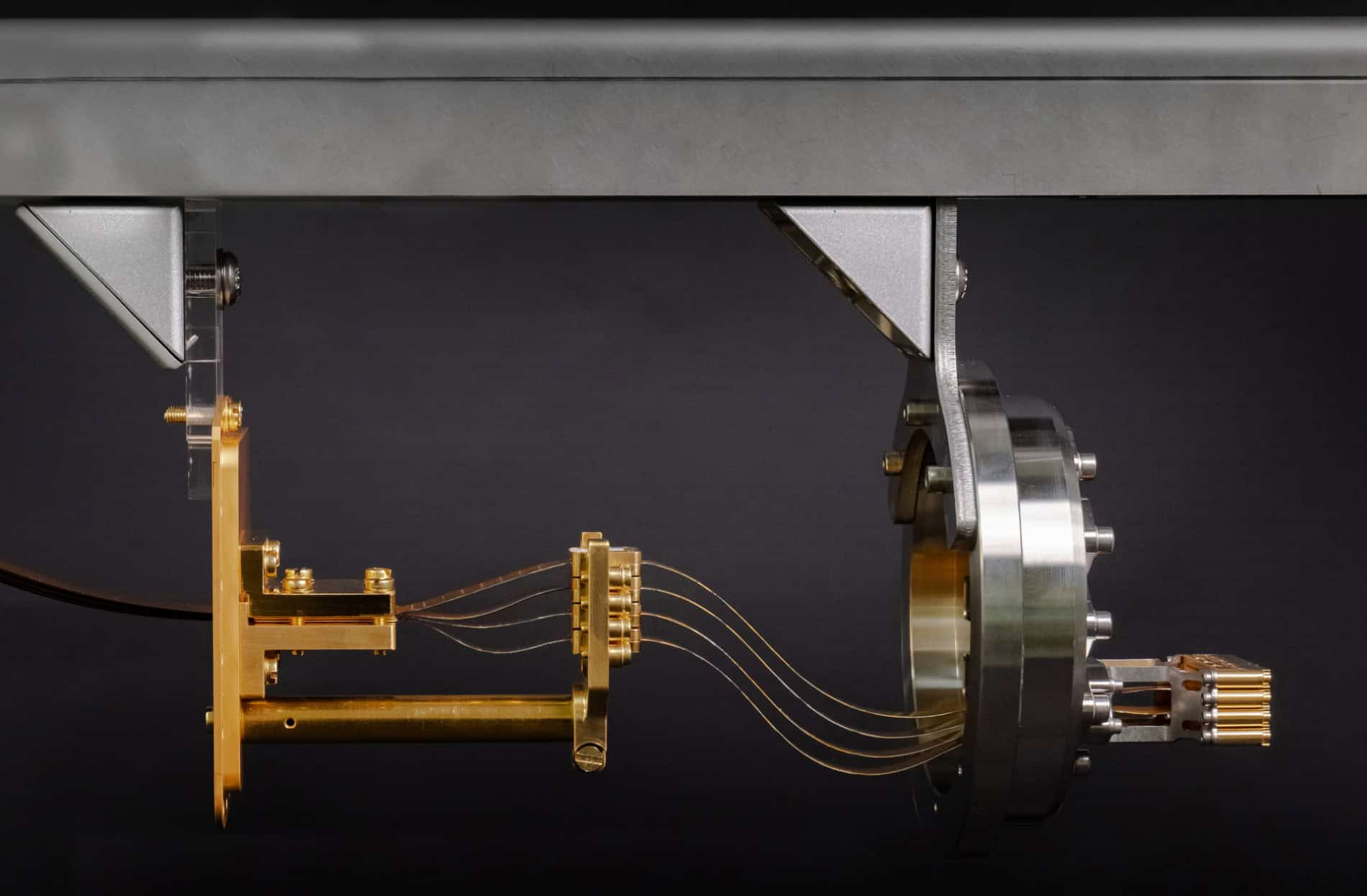

- Additive Manufacturing of Core Components: Researchers developed and validated novel 3D-printed components, including multimaterial rotor cores, custom conductors, and a fully printable stator concept with support-free overhangs.

- Hybrid Magnet Compositions: Optimized designs utilized hybrid magnet compositions, combining sintered and printed polymer-bonded magnets to achieve material cost reductions of up to 8.75%.

Analysis of Key Outcomes and Performance Metrics

Generator Performance and Validation

The project successfully demonstrated the viability of its innovations through both conceptual designs and physical prototypes, contributing to the advancement of SDG 7.

- Conceptual designs for 15 MW offshore generators achieved torque estimates exceeding 20.4 MNm.

- A 15 kW prototype generator designed for Bergey WindPower was manufactured and tested. Experimental validation confirmed a strong correlation with simulation data, showing torque measurement differences of less than 10%.

Broader Implications for Sustainable Development

Supporting National and Global Climate Action (SDG 13)

The outcomes of the MADE3D project directly support climate action strategies by making wind energy a more viable and efficient power source. The research contributes to the DOE’s goal of achieving 30 GW of offshore wind capacity by 2030, a key milestone in the transition to a low-carbon economy.

Fostering a Circular Economy in the Wind Sector (SDG 12)

The project’s emphasis on material reduction and innovative manufacturing aligns with a broader industry trend toward a circular economy. Related initiatives include:

- The development of 3D-printed wind turbine towers to reduce construction costs and logistical challenges.

- The reuse of decommissioned turbine blades as feedstock for 3D-printed infrastructure, such as modular bridges.

The open-access design files, publications, and workflows from the MADE3D project provide a lasting contribution, enabling continued innovation across the renewable energy sector and supporting the global pursuit of sustainable development.

Analysis of Sustainable Development Goals (SDGs) in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

-

SDG 7: Affordable and Clean Energy

The article’s central theme is the advancement of wind energy technology, a key source of clean energy. The MADE3D project aims to improve the “performance and scalability of next-generation wind energy systems,” directly contributing to making clean energy more accessible and efficient.

-

SDG 9: Industry, Innovation, and Infrastructure

The project is a clear example of industrial innovation. It focuses on “new approaches to wind turbine generator design and manufacturing, using additive technologies” like 3D printing and machine learning tools (MADE3D-AML). This enhances technological capabilities and builds resilient infrastructure (wind turbines).

-

SDG 12: Responsible Consumption and Production

The initiative promotes sustainable production patterns by designing systems that “reduce rare-earth material dependency.” It achieves “weight reductions of up to 35% in magnets and 20% in electrical steel,” demonstrating more efficient use of natural resources. The mention of “reusing decommissioned turbine blades” also points to circular economy principles.

-

SDG 13: Climate Action

By improving wind energy, the project directly supports efforts to combat climate change. The article states that the research supports the DOE’s broader strategy for offshore wind and that the sector is scaling “toward global decarbonization goals.”

2. What specific targets under those SDGs can be identified based on the article’s content?

-

Target 7.2: Increase substantially the share of renewable energy in the global energy mix.

The entire project is designed to make wind energy, a renewable source, more effective and scalable. The article explicitly mentions that the research supports the “DOE’s broader strategy for achieving 30 GW of offshore wind capacity by 2030,” which is a direct effort to increase the share of renewable energy.

-

Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes.

The article details the use of “additive technologies” and “3D printing” to create generator components. This new manufacturing process leads to increased resource efficiency, evidenced by “weight reductions of up to 35% in magnets and 20% in electrical steel” and a reduction in “rare-earth material dependency.”

-

Target 9.5: Enhance scientific research, upgrade the technological capabilities of industrial sectors in all countries, in particular developing countries, encouraging innovation.

The MADE3D project is a five-year research and innovation initiative funded by the DOE. It brought together multiple research labs (NREL, ORNL) and industry partners to develop novel technologies, such as the “MADE3D-AML tool, a machine learning-based surrogate model for topology optimization,” which significantly accelerates design workflows.

-

Target 12.2: Achieve the sustainable management and efficient use of natural resources.

The project’s success in reducing the material inputs for wind turbine generators is a direct contribution to this target. The article highlights the reduction of “rare-earth material dependency” and achieving “magnet material costs by up to 8.75%” through more efficient designs and material compositions.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

-

Indicators for Target 7.2

A specific, measurable indicator is provided: The goal of achieving “30 GW of offshore wind capacity by 2030.” The development of 15 kW and conceptual 15 MW generators also serves as a metric for scaling up capacity.

-

Indicators for Target 9.4

The article provides several quantitative indicators of increased resource-use efficiency:

- Weight reduction of up to 35% in magnets.

- Weight reduction of up to 20% in electrical steel.

- Reduction in magnet material costs by up to 8.75%.

-

Indicators for Target 12.2

The indicators for resource efficiency are the same as for Target 9.4, specifically the quantifiable reductions in the use of materials like rare-earth elements and electrical steel. The project’s focus on reducing “rare-earth material dependency” is a key qualitative indicator.

4. Summary Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 7: Affordable and Clean Energy | 7.2: Increase substantially the share of renewable energy in the global energy mix. |

|

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies. |

|

| SDG 12: Responsible Consumption and Production | 12.2: Achieve the sustainable management and efficient use of natural resources. |

|

| SDG 13: Climate Action | 13.2: Integrate climate change measures into national policies, strategies and planning. |

|

Source: 3dprintingindustry.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

.jpg?#)