Pennsylvania Manufacturing Powers $112B Economy – Thomasnet

Report on the State of Pennsylvania’s Manufacturing Sector and its Alignment with Sustainable Development Goals

Executive Summary

Pennsylvania’s manufacturing sector serves as a cornerstone of the state’s economy, contributing significantly to economic growth and employment. This report analyzes the historical evolution, current landscape, and future trajectory of the industry, with a specific focus on its alignment with the United Nations’ Sustainable Development Goals (SDGs). The sector’s output exceeds $112 billion annually, with 13,058 firms employing 693,521 workers, underscoring its critical role in achieving SDG 8: Decent Work and Economic Growth.

Historical Context: The Evolution of Industry and Infrastructure

Pennsylvania’s manufacturing legacy is rooted in its position within the “Rust Belt,” a region defined by its industrial prowess. The state’s development was propelled by abundant natural resources, which facilitated the growth of foundational industries and the establishment of resilient infrastructure, a key component of SDG 9: Industry, Innovation, and Infrastructure.

- 18th Century: The establishment of the first cold blast furnace in 1730 marked the beginning of large-scale iron and steel production. Abundant timber resources supported the growth of Philadelphia and Pittsburgh as major shipbuilding centers.

- 19th Century: Pennsylvania became the national leader in iron and steel. The discovery of anthracite coal further fueled industrial output. The textile and glassmaking industries also flourished, diversifying the state’s industrial base.

- 20th Century: The manufacturing sector played a pivotal role during World War I and World War II, expanding production and diversifying its workforce. This period saw a significant influx of women and Black Americans into manufacturing jobs, representing an early move toward SDG 5: Gender Equality and SDG 10: Reduced Inequalities.

Contemporary Landscape: A Transition to Sustainable and Innovative Models

The late 20th century presented challenges, including foreign competition and offshoring, leading to economic decline in traditional industries. However, the sector has undergone a modern renaissance, driven by investments in technology and automation. This transition aligns with the principles of SDG 9 by fostering innovation and upgrading industrial capabilities for sustainability.

Today, Pennsylvania’s leading industries demonstrate a broad contribution to various SDGs:

- Food and Beverage Production: Supports SDG 2: Zero Hunger by contributing to stable food supply chains.

- Chemicals and Specialty Plastics: Drives innovation in materials science.

- Wood and Paper Products: Emphasizes the need for sustainable resource management.

- Pharmaceuticals and Medical Devices: Directly contributes to SDG 3: Good Health and Well-being.

- Fabricated Metals, Heavy Machinery, and Equipment: Provides the essential components for building resilient infrastructure (SDG 9).

Key Corporate Contributors to Sustainable Development

Several major corporations in Pennsylvania are actively contributing to the SDGs through their operations and strategic initiatives.

East Penn Manufacturing

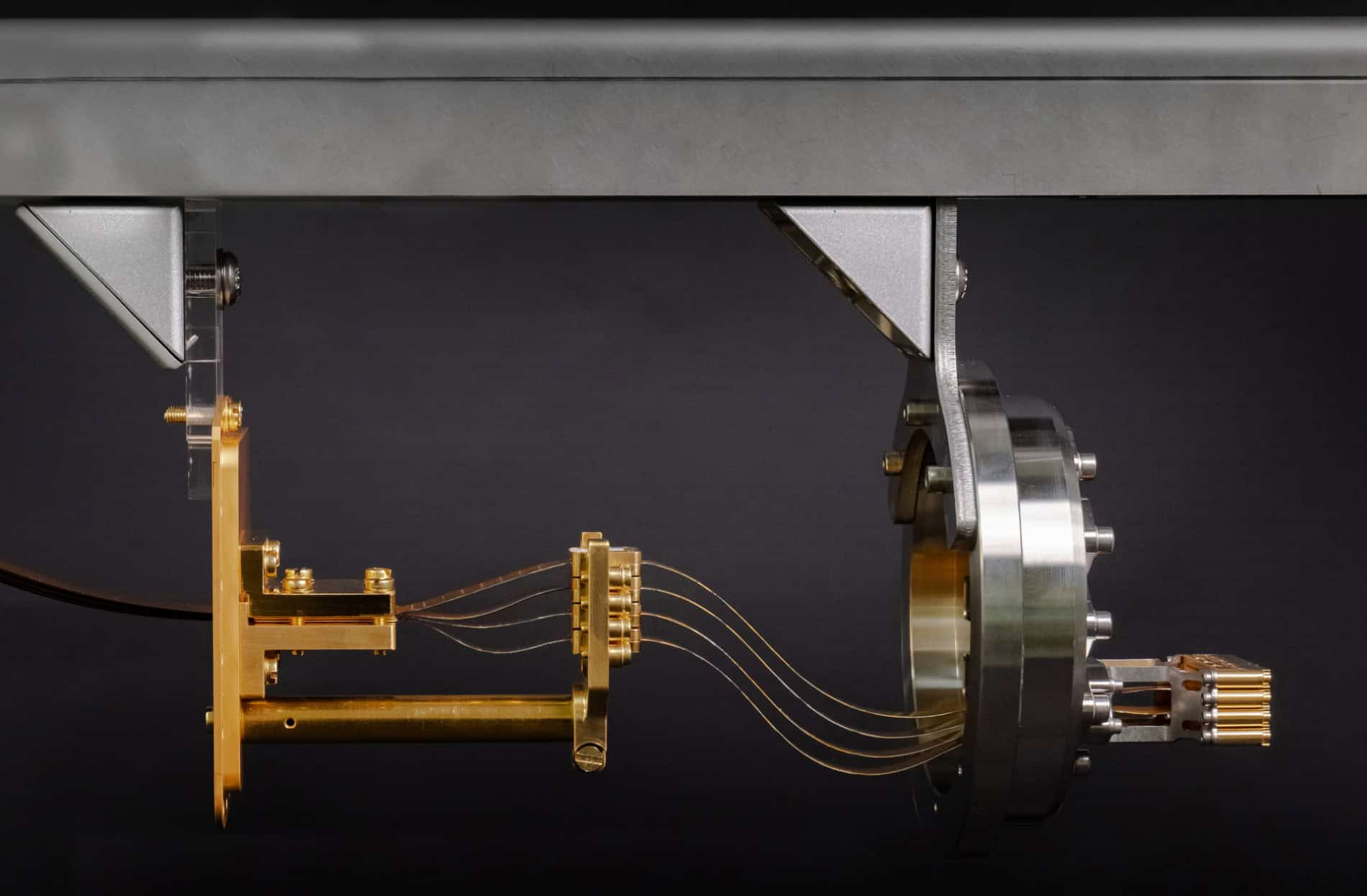

A leading battery manufacturer that exemplifies SDG 12: Responsible Consumption and Production. The company’s facility in Berks County is the world’s largest single-site, lead-acid battery facility. Critically, it recycles nearly 100% of each spent battery it processes, demonstrating a commitment to a circular economy.

Kraft-Heinz

As the world’s fifth-largest food and beverage company, Kraft-Heinz contributes to SDG 2 by producing globally trusted food products. Its planned $3 billion investment in U.S. manufacturing facilities will create thousands of jobs, directly supporting SDG 8 by promoting sustained, inclusive, and sustainable economic growth.

U.S. Steel

A foundational steel producer that serves industries crucial for modern society, including construction, energy, and automotive. By supplying high-value steel products, U.S. Steel provides the materials necessary for developing resilient infrastructure and sustainable cities, aligning with SDG 9 and SDG 11: Sustainable Cities and Communities.

PPG Industries

A global supplier of paints, coatings, and specialty materials that actively pursues sustainable innovation (SDG 9). In 2024, 41% of the company’s $15.8 billion in sales came from sustainably advantaged products, a direct contribution to SDG 12 by promoting resource-efficient and environmentally sound production patterns.

Air Products

A leading industrial gas company demonstrating a strong commitment to clean energy. The company is a key partner in developing the world’s largest green-hydrogen-based ammonia production facility. This project directly addresses SDG 7: Affordable and Clean Energy and SDG 13: Climate Action by aiming to eliminate five million metric tonnes of carbon emissions annually.

Future Outlook: A Strategic Vision for Sustainable Growth

The future of Pennsylvania’s manufacturing sector is guided by strategic initiatives aimed at fostering sustainable economic growth and innovation.

- Government Support: The state administration is focused on streamlining regulations and expediting permitting to enhance competitiveness, creating a policy environment conducive to achieving SDG 8 and SDG 9. The new, fully-integrated digital manufacturing plant for the Hershey Company is a recent example of this progress.

- Vision 2030 Strategy: This advanced manufacturing strategy sets a course to grow the sector’s economic impact to $180 billion by 2030. The plan aims to fuel economic growth, create family-sustaining jobs, and revitalize supply chains, with projections suggesting the creation of 368,000 jobs. This vision strongly aligns with the objectives of SDG 8 and SDG 9, positioning Pennsylvania as a leader in sustainable industrial development.

1. Which SDGs are addressed or connected to the issues highlighted in the article?

- SDG 8: Decent Work and Economic Growth – The article extensively discusses the manufacturing sector’s contribution to Pennsylvania’s economy, employment figures, and future growth strategies.

- SDG 9: Industry, Innovation and Infrastructure – The text focuses on the history, current state, and future of the manufacturing industry, including technological advancements, infrastructure development, and innovation.

- SDG 12: Responsible Consumption and Production – The article provides a specific example of a company implementing advanced recycling processes to minimize waste.

- SDG 13: Climate Action – There is a mention of a major project aimed at producing green energy and significantly reducing carbon emissions.

- SDG 5: Gender Equality – The article historically notes the entry of women into the manufacturing workforce.

- SDG 10: Reduced Inequalities – The text historically references the inclusion of Black Americans in the state’s manufacturing sector.

2. What specific targets under those SDGs can be identified based on the article’s content?

SDG 8: Decent Work and Economic Growth

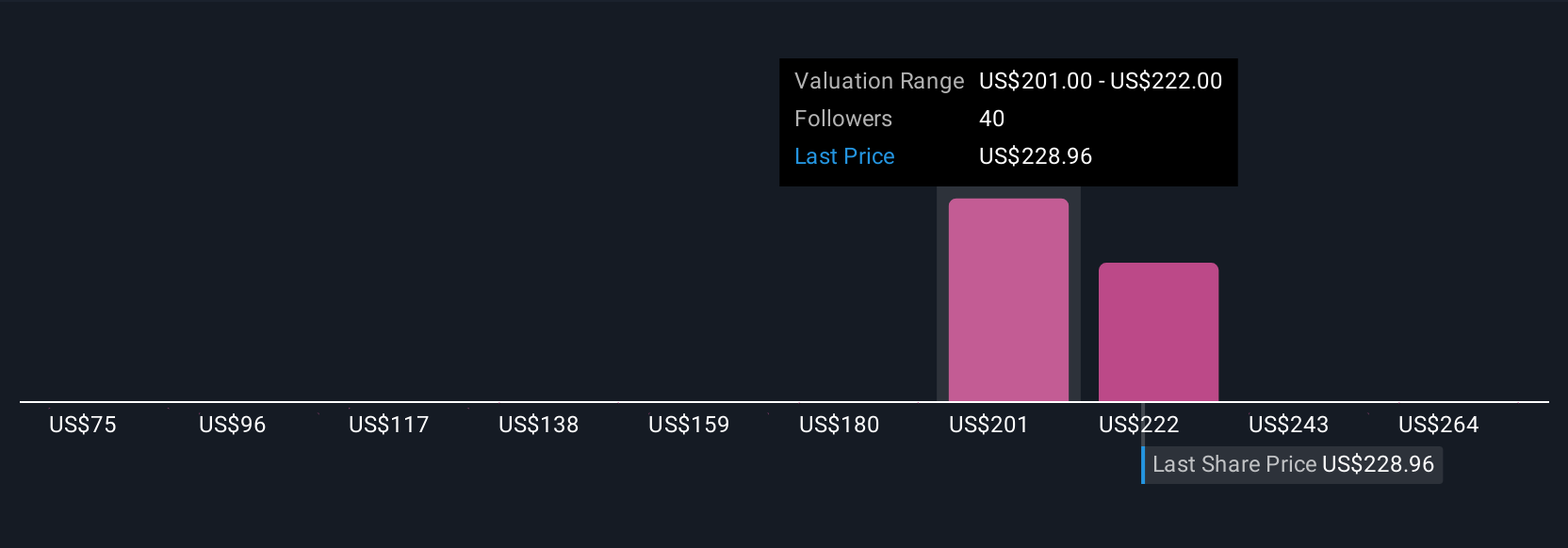

- Target 8.1: Sustain per capita economic growth in accordance with national circumstances and, in particular, at least 7 per cent gross domestic product growth per annum in the least developed countries. The article highlights that the sector produces over “$112 billion annually” and the “Vision 2030” strategy aims to grow the economic impact to “$180 billion by 2030.”

- Target 8.2: Achieve higher levels of economic productivity through diversification, technological upgrading and innovation, including through a focus on high-value added and labour-intensive sectors. The article notes a “renaissance, with investments in new technologies and automation, including robotics, automation, and AI, driving company profits and productivity.”

- Target 8.5: By 2030, achieve full and productive employment and decent work for all women and men, including for young people and persons with disabilities, and equal pay for equal value. The article states the sector “employs 693,521 workers” and that future initiatives could “create 368,000 jobs.”

SDG 9: Industry, Innovation and Infrastructure

- Target 9.2: Promote inclusive and sustainable industrialization and, by 2030, significantly raise industry’s share of employment and gross domestic product, in line with national circumstances, and double its share in least developed countries. The entire article is a testament to this target, detailing the scale of Pennsylvania’s manufacturing industry with “13,058 manufacturing firms” and its significant role in the state’s economy.

- Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with all countries taking action in accordance with their respective capabilities. The article mentions East Penn Manufacturing’s facility as “the world’s largest single-site, lead-acid battery facility, offering world-class facilities that are the most advanced in the industry” and Air Products’ project for a “green-hydrogen-based ammonia production facility run on renewable energy.”

- Target 9.5: Enhance scientific research, upgrade the technological capabilities of industrial sectors in all countries, in particular developing countries, including, by 2030, encouraging innovation and substantially increasing the number of research and development workers per 1 million people and public and private research and development spending. The article points to PPG’s “Coatings Innovation Center” and “Monroeville Business and Technology Center” as examples of dedicated innovation facilities.

SDG 12: Responsible Consumption and Production

- Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse. The article explicitly states that East Penn Manufacturing “recycles almost 100% of each spent battery it receives for processing.”

SDG 13: Climate Action

- Target 13.2: Integrate climate change measures into national policies, strategies and planning. Air Products’ partnership to establish a facility that “will save the world about five million metric tonnes per year of carbon emissions” is a direct corporate action contributing to this target.

SDG 5: Gender Equality

- Target 5.5: Ensure women’s full and effective participation and equal opportunities for leadership at all levels of decision-making in political, economic and public life. The article provides a historical reference, noting that during WW1 and WW2, “women and Black Americans enter[ed] the state’s manufacturing workforce in record numbers.”

SDG 10: Reduced Inequalities

- Target 10.2: By 2030, empower and promote the social, economic and political inclusion of all, irrespective of age, sex, disability, race, ethnicity, origin, religion or economic or other status. The historical mention of “Black Americans enter[ing] the state’s manufacturing workforce in record numbers” during the world wars relates to this target.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

For Target 8.1 (Sustain economic growth):

- Indicator: The annual economic output of the manufacturing sector. The article provides a baseline of “$112 billion annually” and a 2030 target of “$180 billion.”

For Target 8.5 (Full and productive employment):

- Indicator: Number of people employed in the manufacturing sector. The article gives a current figure of “693,521 workers” and a projected creation of “368,000 jobs.”

For Target 9.2 (Promote inclusive and sustainable industrialization):

- Indicator: Number of manufacturing firms. The article states there are “13,058 manufacturing firms” in Pennsylvania.

For Target 12.5 (Substantially reduce waste generation):

- Indicator: Recycling rate of specific industrial products. The article mentions that East Penn Manufacturing “recycles almost 100% of each spent battery” and processes “more than 30,000 batteries daily.”

For Target 13.2 (Integrate climate change measures):

- Indicator: Reduction in carbon emissions from industrial projects. The article specifies that the Air Products green hydrogen project will save “about five million metric tonnes per year of carbon emissions.”

4. SDGs, Targets and Indicators Table

| SDGs | Targets | Indicators Identified in the Article |

|---|---|---|

| SDG 8: Decent Work and Economic Growth | 8.1: Sustain per capita economic growth. 8.2: Achieve higher levels of economic productivity through innovation. 8.5: Achieve full and productive employment. |

– Annual economic output: $112 billion, with a target of $180 billion by 2030. – Investment in robotics, automation, and AI. – Current employment: 693,521 workers. – Projected job creation: 368,000 jobs. |

| SDG 9: Industry, Innovation and Infrastructure | 9.2: Promote inclusive and sustainable industrialization. 9.4: Upgrade infrastructure and retrofit industries to make them sustainable. 9.5: Enhance scientific research and upgrade technological capabilities. |

– Number of firms: 13,058 manufacturing firms. – Development of advanced facilities (e.g., East Penn’s battery site, Hershey’s digital plant). – Establishment of innovation centers (e.g., PPG’s centers). |

| SDG 12: Responsible Consumption and Production | 12.5: Substantially reduce waste generation through recycling. | – Recycling rate: “almost 100% of each spent battery” is recycled by East Penn Manufacturing. – Volume processed: “more than 30,000 batteries daily.” |

| SDG 13: Climate Action | 13.2: Integrate climate change measures into policies and strategies. | – Carbon emission reduction: “five million metric tonnes per year” saved by the green hydrogen project. |

| SDG 5: Gender Equality | 5.5: Ensure women’s full and effective participation in economic life. | – Historical data point: Women entering the manufacturing workforce in record numbers during WW1 and WW2. |

| SDG 10: Reduced Inequalities | 10.2: Promote the social and economic inclusion of all, irrespective of race. | – Historical data point: Black Americans entering the manufacturing workforce in record numbers during WW1 and WW2. |

Source: thomasnet.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0