The extreme robot arm that can chop up a ship

The extreme robot arm that can chop up a ship BBC.com

A New Approach to Ship Recycling: Sustainable Solutions for a Dirty Industry

By Chris Baraniuk, Technology of Business reporter

Leviathan

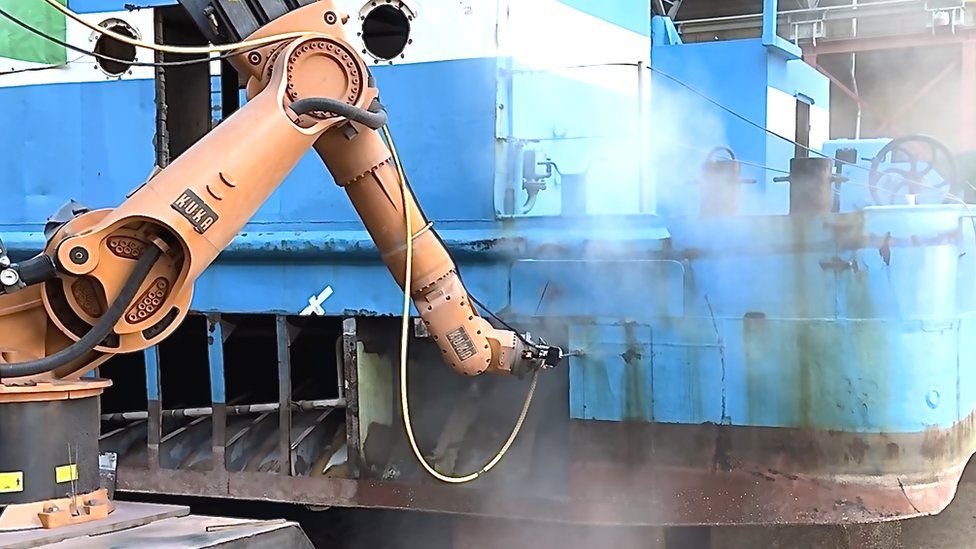

A huge robotic arm, wielding a waterjet powerful enough to slice through steel, swings into action.

It is chopping up the hull of a large ship. The structure, which withstood the power of the sea for decades, yields easily to the cutting jet. Before long, the robot has sliced out a big rectangle of steel.

Its task complete, the machine silently moves on to the next section.

“You can have robots starting at the bow and the stern, and two points in the middle, and working towards each other,” says Bryce Lawrence, operations director at Leviathan. The firm, based in Germany, plans to use a team of robots to dismantle huge ships so that the steel can be recycled.

Today’s shipbreaking industry is one of the dirtiest and most exploitative in the world.

When mammoth vessels retire from years of ferrying cargo such as consumer goods, or oil, between continents, they often end up on a heavily polluted beach somewhere in South Asia. There, workers use fossil fuel-powered torches to painstakingly dismantle the ships. Protective clothing is scarce. Fatalities are not.

Getty Images

Contaminants, including heavy metals, often get washed into the sea from these beaches. Workers and local communities are frequently exposed to dangerous materials including asbestos. During the next decade, 15,000 ships will require recycling – more than double the volume of the past decade, estimates Bimco, the Baltic and International Maritime Council.

Leviathan and other companies are trying to find ways of doing this work much more cleanly and safely. Still, there are no guarantees that they will be able to compete with the dirt-cheap yards of South Asia.

“Compared to traditional ship recycling, we’re very, very low carbon,” says Mr Lawrence as he explains how machinery at Leviathan’s Stralsund facility on Germany’s Baltic coast will be powered by electricity, not on-site fossil fuels, and that recovered steel will be transported to mills around Europe on electrified trains. Commercial operations are expected to start in the coming months, he adds.

The firm’s prototype system is a mash-up of established technologies. The robot arms are the sort that toil in car factories, for example, and the waterjet is manufactured by ANT AG, another German firm.

This device blasts a mixture of water and sand at high pressures – a technology so precise that it is used by bomb disposal experts to cut the fuses out of bombs.

“Somebody has to approach the bomb, put the manipulating system on,” says Till Weber, ANT AG’s general manager, “then go as far away as possible.” Mercifully, in such situations the jet can be operated from a distance of half a kilometer. It is currently in use in Ukraine, adds Mr Weber.

ANT

When it comes to ship cutting, such a system requires far fewer workers than traditional shipbreaking does, and Mr Lawrence argues that it could one day complete the job much faster. Computer software being developed by Leviathan will automatically plan how to chop up a vessel as efficiently as possible.

On the other hand, there’s a cost to all this and the robot arms must be properly mounted on special rigs fixed to a dry dock. You can’t just plonk them on a beach.

Sefer Gunbeyaz at the University of Strathclyde has studied workers’ exposure to toxic materials at shipbreaking facilities in the UK and Spain. Even in these countries, exposure – particularly to lead and iron particles – was “worrying”, he and colleagues found.

“It’s a promising start,” he says, of the waterjet-based system in Germany. However, he notes that contaminants in the water used for cutting up ships must still be carefully managed.

Mr Lawrence explains that the Stralsund facility will feature a containment area designed to capture jet water and toxic substances that have been blasted off the ships. Once carefully decontaminated, this water can be reused for further cutting.

Elegant Exit Company, headquartered in The Netherlands, also says it can dismantle ships responsibly. Earlier this year, it began recycling the Wan Hai 165, a 160m-long container vessel.

Elegant Exit Company

Recycling ships has been a dirty business for too long, says Ingvild Jenssen, founder and director of Shipbreaking Platform, a non-governmental organization that monitors the industry.

“What is even more shocking is that you have a whole shipping sector that is well aware of the problems,” she adds.

Some ship owners attempt to send vessels from Europe to South Asian shipbreaking yards despite such exports being illegal.

SDGs, Targets, and Indicators

1. Which SDGs are addressed or connected to the issues highlighted in the article?

- SDG 12: Responsible Consumption and Production

- SDG 14: Life Below Water

- SDG 15: Life on Land

- SDG 8: Decent Work and Economic Growth

2. What specific targets under those SDGs can be identified based on the article’s content?

- SDG 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling, and reuse.

- SDG 14.1: By 2025, prevent and significantly reduce marine pollution of all kinds, particularly from land-based activities, including marine debris and nutrient pollution.

- SDG 15.5: Take urgent and significant action to reduce the degradation of natural habitats, halt the loss of biodiversity, and protect and prevent the extinction of threatened species.

- SDG 8.8: Protect labor rights and promote safe and secure working environments for all workers, including migrant workers, in particular women migrants, and those in precarious employment.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

- Indicator for SDG 12.5: Waste generation per capita

- Indicator for SDG 14.1: Marine pollution index

- Indicator for SDG 15.5: Extent of protected areas

- Indicator for SDG 8.8: Occupational safety and health (OSH) data

Table: SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 12: Responsible Consumption and Production | Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling, and reuse. | Indicator: Waste generation per capita |

| SDG 14: Life Below Water | Target 14.1: By 2025, prevent and significantly reduce marine pollution of all kinds, particularly from land-based activities, including marine debris and nutrient pollution. | Indicator: Marine pollution index |

| SDG 15: Life on Land | Target 15.5: Take urgent and significant action to reduce the degradation of natural habitats, halt the loss of biodiversity, and protect and prevent the extinction of threatened species. | Indicator: Extent of protected areas |

| SDG 8: Decent Work and Economic Growth | Target 8.8: Protect labor rights and promote safe and secure working environments for all workers, including migrant workers, in particular women migrants, and those in precarious employment. | Indicator: Occupational safety and health (OSH) data |

Note: The specific indicators mentioned in the table are examples and may not be the only indicators relevant to measuring progress towards the identified targets.

Behold! This splendid article springs forth from the wellspring of knowledge, shaped by a wondrous proprietary AI technology that delved into a vast ocean of data, illuminating the path towards the Sustainable Development Goals. Remember that all rights are reserved by SDG Investors LLC, empowering us to champion progress together.

Source: bbc.com

Join us, as fellow seekers of change, on a transformative journey at https://sdgtalks.ai/welcome, where you can become a member and actively contribute to shaping a brighter future.