Why Does 3D Printed Stainless Steel Corrode in a Marine Environment? – 3Dnatives

Why Does 3D Printed Stainless Steel Corrode in a Marine Environment? 3Dnatives

Why is 3D printed 316L stainless steel prone to pitting corrosion in seawater?

Researchers from Lawrence Livermore National Laboratory have conducted a thorough study on the pitting corrosion of 3D printed 316L stainless steel in seawater. This metal is commonly used in naval applications and understanding the causes of its degradation is crucial. The study suggests that slag, left behind during laser melting, accumulates on the surface of the material, leading to the formation of cavities or pits. This research aligns with the Sustainable Development Goals (SDGs), particularly SDG 9: Industry, Innovation, and Infrastructure, as it aims to improve the performance and durability of materials used in industrial applications.

Corrosion and Pitting Corrosion

Metals used in various industries are susceptible to corrosion, which is the degradation caused by chemical reactions in the environment. Pitting corrosion is a specific form of corrosion where the metal’s protective oxide layer is degraded, resulting in the formation of small holes or pits. When exposed to an aquatic environment, an electrochemical reaction occurs, exacerbating the pitting corrosion. The severity of the damage depends on the depth of these cavities. Controlling pitting corrosion in seawater is particularly challenging, which is why 316L stainless steel is commonly used in naval applications due to its resistance to this type of corrosion. This research contributes to SDG 14: Life Below Water, as it aims to enhance the durability and performance of materials in marine environments.

Metal degradation (or corrosion).

Research on 3D Printed 316L Stainless Steel

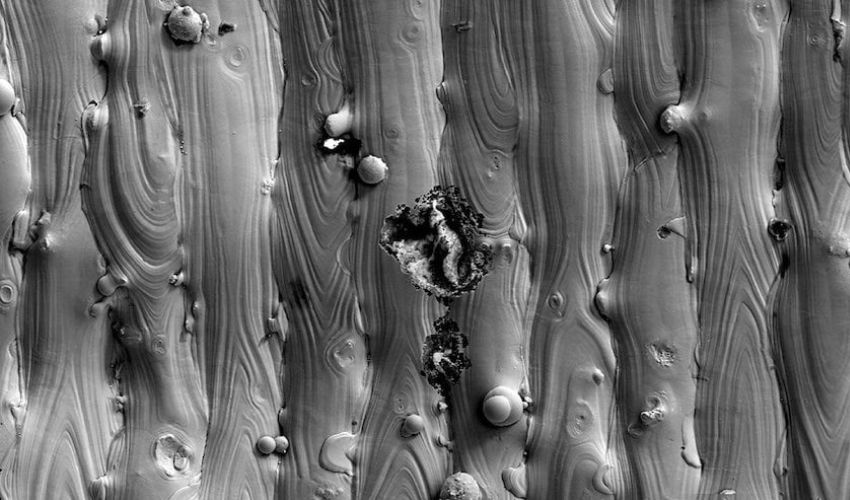

The study conducted by Lawrence Livermore National Laboratory focused on investigating the pitting corrosion phenomenon in 3D printed 316L stainless steel. The researchers discovered that the presence of slag, created by deoxidizers like silicon and manganese, was responsible for this corrosion. Unlike traditional manufacturing processes where slag can be removed using tools like grinders, post-treatment methods are not applicable in additive manufacturing. By utilizing techniques such as transmission electron microscopy and ion beam milling, the researchers closely examined the slag present in the 3D printed metal and identified its role in enabling seawater infiltration and subsequent degradation. This research contributes to SDG 12: Responsible Consumption and Production, as it aims to improve the sustainability and longevity of materials used in manufacturing processes.

Laser melting on a powder bed could provide a better understanding of pitting corrosion.

Implications and Future Directions

The researchers concluded that 3D printed 316L stainless steel can effectively mitigate pitting corrosion if the formulation of the metal powder is altered to remove silicon and manganese. This discovery opens up possibilities for modifying the material’s mechanical properties and enhancing its corrosion resistance, expanding its potential applications. By understanding the mechanisms underlying slagging, components with improved water resistance, durability, and structural integrity can be designed. This research aligns with SDG 11: Sustainable Cities and Communities, as it contributes to the development of sustainable materials for infrastructure and construction purposes.

The study’s lead author, Shohini Sen-Britain, stated, “It is confirming, again and again, that we can use laser powder bed fusion additive manufacturing to improve our material properties, way beyond anything we can do with other techniques.” This highlights the potential of additive manufacturing in advancing material science and achieving the SDGs.

To learn more about this project, click here.

*All Photo Credits: Thomas Voisin/LLNL

SDGs, Targets, and Indicators

1. Which SDGs are addressed or connected to the issues highlighted in the article?

- SDG 9: Industry, Innovation, and Infrastructure

- SDG 14: Life Below Water

2. What specific targets under those SDGs can be identified based on the article’s content?

- SDG 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes.

- SDG 14.1: By 2025, prevent and significantly reduce marine pollution of all kinds, in particular from land-based activities, including marine debris and nutrient pollution.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

- Indicator for SDG 9.4: Proportion of industries upgraded to sustainable practices

- Indicator for SDG 14.1: Amount of marine pollution from land-based activities

4. Table: SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 9: Industry, Innovation, and Infrastructure | Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes. | Indicator: Proportion of industries upgraded to sustainable practices |

| SDG 14: Life Below Water | Target 14.1: By 2025, prevent and significantly reduce marine pollution of all kinds, in particular from land-based activities, including marine debris and nutrient pollution. | Indicator: Amount of marine pollution from land-based activities |

Explanation:

The article discusses the issue of pitting corrosion in 3D printed stainless steel, which is relevant to SDG 9 (Industry, Innovation, and Infrastructure) and SDG 14 (Life Below Water). Under SDG 9, the specific target of upgrading infrastructure and retrofitting industries to make them sustainable (Target 9.4) is addressed. The article explores the degradation of the material and the need for understanding and improving its corrosion resistance. This aligns with the target of adopting clean and environmentally sound technologies and industrial processes.

Under SDG 14, the target of preventing and reducing marine pollution (Target 14.1) is relevant. The article highlights the impact of pitting corrosion in seawater, which can lead to degradation of marine components. By addressing the causes of pitting corrosion and finding ways to enhance corrosion resistance, progress can be made towards reducing marine pollution.

The indicators mentioned in the article are implied rather than explicitly stated. For SDG 9.4, the proportion of industries upgraded to sustainable practices can be used as an indicator to measure progress. For SDG 14.1, the amount of marine pollution from land-based activities can be used as an indicator to track progress in reducing pollution caused by pitting corrosion and other forms of degradation.

Behold! This splendid article springs forth from the wellspring of knowledge, shaped by a wondrous proprietary AI technology that delved into a vast ocean of data, illuminating the path towards the Sustainable Development Goals. Remember that all rights are reserved by SDG Investors LLC, empowering us to champion progress together.

Source: 3dnatives.com

Join us, as fellow seekers of change, on a transformative journey at https://sdgtalks.ai/welcome, where you can become a member and actively contribute to shaping a brighter future.