Holcim Mexico accelerates industrial decarbonisation through strategic investments and circular waste management – World Cement

Report on Holcim Mexico’s Decarbonization and Circular Economy Initiatives

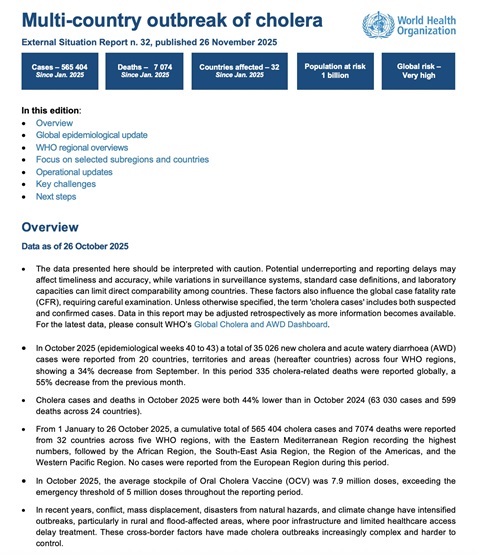

Executive Summary

Holcim Mexico, through its subsidiary Geocycle, is advancing its decarbonization roadmap by implementing a circular co-processing model. This initiative transforms various waste streams into alternative fuels and raw materials, directly contributing to several United Nations Sustainable Development Goals (SDGs). Strategic investments in infrastructure have enabled significant progress in replacing fossil fuels, managing waste, and reducing carbon emissions, positioning the company as a leader in sustainable construction. This report outlines the key projects, investments, and achievements in alignment with global sustainability targets.

Strategic Investment and Infrastructure Development

Holcim has made substantial financial commitments to enhance its operational capacity for sustainable practices. These investments are foundational to achieving long-term environmental and economic goals.

Alignment with SDG 9: Industry, Innovation, and Infrastructure

- Over the past four years, a strategic investment of more than CHF 20 million has been allocated to key infrastructure projects.

- This funding is focused on increasing waste-handling capacity and accelerating the replacement of fossil fuels in cement production.

- A key project includes the installation of a new tire shredder at the Hermosillo plant, enhancing the facility’s ability to process complex waste streams and build resilient, sustainable infrastructure.

Circular Economy and Waste Management

The core of Holcim Mexico’s strategy is a circular economy model that addresses significant environmental challenges, such as the management of municipal solid waste and scrap tires.

Contribution to SDG 11 (Sustainable Cities and Communities) and SDG 12 (Responsible Consumption and Production)

By transforming waste into valuable resources, Holcim supports the development of sustainable communities and promotes responsible production patterns. Key achievements include:

- Management of over 100,000 tonnes of scrap tires since 2024, mitigating pollution sources and health risks associated with conventional disposal.

- Annual processing of over 550,000 tonnes of industrial, commercial, municipal, and agricultural waste.

- This circular approach directly contributes to a reduction of more than 1.5 million tonnes of CO2 emissions, fostering cleaner and safer urban environments.

Decarbonization and Climate Action

A primary objective of the initiative is the decarbonization of the construction industry through the reduction of greenhouse gas emissions and reliance on fossil fuels.

Progress Towards SDG 7 (Affordable and Clean Energy) and SDG 13 (Climate Action)

The Hermosillo plant serves as a benchmark for the successful transition to cleaner energy sources. The project’s progress demonstrates a tangible commitment to climate action:

- Complete replacement of fossil fuels (petcoke) in the kiln with energy derived from waste tires.

- Increase in the plant’s thermal substitution rate (TSR) from 52.4% in 2023 to a projected 60% in 2025.

- A stated goal to surpass an 85% TSR in the coming years, significantly reducing the carbon footprint of cement production.

Replication, Future Outlook, and International Recognition

The success of the Hermosillo project has established a replicable model for other facilities and has garnered international acclaim, reinforcing the viability of Holcim’s sustainability strategy.

Scaling Sustainable Practices and Long-Term Goals

Holcim Mexico plans to scale this model across all its national operations, reinforcing its commitment to sustainable development.

- The company aims to achieve a national TSR of 70% by 2030.

- The Tecomán plant is projected to reach a TSR above 80% by the end of the current year.

- These efforts align with the global corporate goal of becoming a net-zero company by 2050, contributing to SDG 8 (Decent Work and Economic Growth) by fostering a green economy.

Global CemFuels Award

The Hermosillo project was recognized as the “Outstanding Alternative Fuel Project of the Year” at the Global CemFuels Conference & Exhibition 2025. This award validates the project’s innovative approach to converting waste into clean energy and its significant contribution to industrial decarbonization and the broader Sustainable Development Goals.

Analysis of Sustainable Development Goals in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

- SDG 3: Good Health and Well-being: The article explicitly mentions that managing scrap tires eliminates “health risks” associated with pollution.

- SDG 9: Industry, Innovation and Infrastructure: The article focuses on Holcim’s investment in infrastructure, technological innovation (tire shredder, co-processing), and upgrading its industrial processes to be more sustainable and efficient.

- SDG 11: Sustainable Cities and Communities: The initiative addresses the management of municipal solid waste and scrap tires, which are significant environmental challenges for communities, thereby reducing the adverse environmental impact of cities.

- SDG 12: Responsible Consumption and Production: The core of the article is about creating a “circular co-processing model” that transforms waste into energy and raw materials, directly addressing sustainable waste management and reducing waste generation.

- SDG 13: Climate Action: A primary goal of the project is to accelerate decarbonisation, reduce CO2 emissions, and replace fossil fuels, which are direct actions to combat climate change.

2. What specific targets under those SDGs can be identified based on the article’s content?

- Target 3.9: By 2030, substantially reduce the number of deaths and illnesses from hazardous chemicals and air, water and soil pollution and contamination.

- The article supports this by stating that Holcim’s project to manage scrap tires “eliminates pollution sources and health risks” for the nationwide population.

- Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes.

- The article details Holcim’s investment of “over CHF 20 million in key infrastructure” and the installation of a “new tire shredder” to adopt advanced waste-processing technology, making its cement production more sustainable.

- Target 11.6: By 2030, reduce the adverse per capita environmental impact of cities, including by paying special attention to air quality and municipal and other waste management.

- The article highlights the management of “municipal solid waste” and “scrap tires,” which it describes as one of “Mexico’s most pressing environmental challenges” and “major sources of pollution.”

- Target 12.4: By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle… and significantly reduce their release to air, water and soil to minimize their adverse impacts on human health and the environment.

- Holcim’s Geocycle subsidiary is described as driving a model that “transforms municipal solid waste, industrial residues, and biomass into new energy resources,” which is a clear example of environmentally sound waste management.

- Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.

- The co-processing model incorporates waste like “100 000 t of scrap tires” and “over 550 000 t of industrial, commercial, and municipal waste” into the production process, effectively recycling and reusing them to prevent them from becoming landfill.

- Target 13.2: Integrate climate change measures into national policies, strategies and planning.

- While the article describes a corporate strategy, Holcim’s commitment to “decarbonizing the construction industry” and achieving its “global goal of becoming a net-zero company by 2050” directly contributes to national and global climate goals by replacing fossil fuels and reducing CO2 emissions.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

- Indicator for Target 9.4 & 13.2 (Thermal Substitution Rate): The Thermal Substitution Rate (TSR) is a key performance indicator used to measure the replacement of fossil fuels. The article provides specific data points: the rate at the Hermosillo plant increased from “52.4% in 2023” with a goal to reach “60% in 2025” and “surpassing 85% in the coming years.” It also mentions a national target of “70% by 2030.”

- Indicator for Target 12.5 & 11.6 (Volume of Waste Managed): The article quantifies the amount of waste diverted from landfills. It states that “Geocycle has managed more than 100 000 t of scrap tires” and that Holcim Mexico processes “over 550 000 t of industrial, commercial, and municipal waste, as well as agricultural residues.”

- Indicator for Target 13.2 (CO2 Emissions Reduction): The article provides a direct measure of climate action impact, stating that the waste processing activities “directly contributing to the reduction of more than 1.5 million t of CO2.”

- Indicator for Target 9.4 (Financial Investment): The financial commitment to upgrading infrastructure is a clear indicator of progress. The article mentions Holcim has invested “more than CHF 20 million in key infrastructure” over the past four years.

- Indicator for Target 3.9 (Elimination of Health Risks): While not a quantitative metric, the article implies a qualitative indicator by stating the project “eliminates pollution sources and health risks,” which is a direct measure of progress towards reducing health impacts from pollution.

4. Summary Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 3: Good Health and Well-being | 3.9: Reduce illnesses from pollution and contamination. | Elimination of pollution sources and health risks associated with scrap tire dumps. |

| SDG 9: Industry, Innovation and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries to make them sustainable. | Investment of over CHF 20 million in infrastructure; Installation of new tire shredder technology. |

| SDG 11: Sustainable Cities and Communities | 11.6: Reduce the adverse environmental impact of cities, particularly in waste management. | Management of over 550,000 t of municipal and industrial waste. |

| SDG 12: Responsible Consumption and Production | 12.4 & 12.5: Achieve environmentally sound management of waste and substantially reduce waste generation. | Processing of over 100,000 t of scrap tires into energy and raw materials through a circular co-processing model. |

| SDG 13: Climate Action | 13.2: Integrate climate change measures into policies and strategies. | Reduction of more than 1.5 million t of CO2; Increase in Thermal Substitution Rate (TSR) to a target of 85% at one plant and 70% nationally by 2030. |

Source: worldcement.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0