In the Search for Ship Energy Efficiency, Don’t Forget Waste Heat – Marine News Magazine

Report on Organic Rankine Cycle Systems and Sustainable Development Goals in the Maritime Sector

Introduction: Enhancing Maritime Energy Efficiency

Organic Rankine Cycle (ORC) waste heat recovery systems are emerging as a critical energy-efficiency technology for the maritime industry. These fuel-agnostic systems, suitable for both newbuilds and retrofits, are pivotal in advancing the sector’s commitment to the United Nations Sustainable Development Goals (SDGs). By converting waste heat into electrical power, ORC technology directly addresses key environmental and economic challenges, fostering a more sustainable and responsible shipping industry.

Alignment with Sustainable Development Goals (SDGs)

The implementation of ORC systems provides a direct and measurable contribution to several SDGs:

- SDG 7 (Affordable and Clean Energy): By generating electricity from an otherwise wasted resource, ORC systems increase the overall energy efficiency of vessels and contribute to the clean energy supply on board.

- SDG 9 (Industry, Innovation, and Infrastructure): The technology represents a significant innovation in sustainable maritime infrastructure, enhancing the efficiency and environmental performance of the shipping industry.

- SDG 12 (Responsible Consumption and Production): ORC systems promote responsible consumption of marine fuels by maximizing the energy extracted from every unit, thereby reducing overall fuel usage and operational expenditures.

- SDG 13 (Climate Action): A primary benefit of reduced fuel consumption is a direct reduction in CO2 and other greenhouse gas emissions, representing a crucial action against climate change.

- SDG 14 (Life Below Water): By lowering emissions and minimizing the carbon footprint of maritime transport, the technology helps mitigate the adverse impacts of shipping on marine ecosystems.

Technological Framework and Application

Principle of Operation

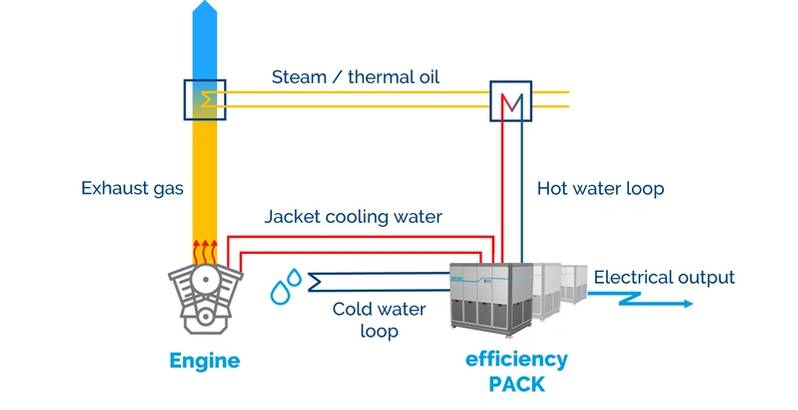

A significant portion of energy from marine combustion engines is lost as waste heat. Analysis indicates that over 50% of this energy is dissipated through exhaust gases and cooling circuits. Approximately half of this recoverable heat is low-temperature (below 100°C). ORC systems are uniquely designed to harness this low-grade thermal energy.

- The system utilizes an organic fluid with a low boiling point.

- Waste heat from sources like jacket water or scavenge air vaporizes the fluid.

- The resulting gas drives a turbine, which generates electricity.

- This process offers a more compact and simpler solution compared to traditional steam-based waste heat recovery systems.

Addressing Inefficiency and Supporting SDG 12

The scale of potential energy recovery is substantial, with estimates suggesting over 100 TWh of waste heat could be harnessed annually in the shipping sector alone. Capturing this energy is a fundamental step toward more responsible production and consumption patterns (SDG 12) by reducing the industry’s reliance on primary fuel sources.

System Innovations and Operational Adaptability

Recent Technological Advancements

To facilitate wider adoption, manufacturers have introduced several key innovations that enhance the technology’s contribution to SDG 9 (Innovation and Infrastructure):

- Modular Design: Compact, modular packages, including skid and split-skid options, have been developed for easier retrofitting in constrained engine room spaces.

- Multi-Source Harvesting: Modern systems can now combine heat from multiple sources—such as exhaust economizers, jacket water, and thermal oil systems—into a single power module for maximized energy recovery.

- Hybrid Integration: Advanced control blocks allow for integration with shaft generators or battery systems, enabling operators to prioritize the use of recovered energy to offset the most expensive power sources on board.

Performance in Diverse Operating Conditions

To address variable engine loads, such as those encountered during slow steaming, new lower-temperature units like the Orcan Energy ePM200 XR have been developed. This unit is optimized for moderate-temperature sources (80–120°C) and can deliver up to 200 kW of net electrical output. By combining high- and low-temperature modules, shipowners can ensure meaningful energy recovery across a vessel’s entire operational profile. This adaptability allows for continued compliance with efficiency regulations and supports climate action (SDG 13) without compromising operational flexibility.

Market Outlook and Synergy with Future Fuels

Compatibility with Alternative Fuels for SDG 7

ORC technology demonstrates strong synergy with alternative marine fuels like methanol, which is crucial for achieving SDG 7 (Affordable and Clean Energy). Vessels operating on methanol often have a more favorable waste heat profile for ORC systems.

- Methanol-fueled engines may require less auxiliary heating, making more waste heat available for electricity generation.

- Systems such as the Climeon HeatPower 300 can operate effectively using only jacket water from methanol engines, without needing a steam boost.

- The improved efficiency and higher electricity generation potential when paired with new fuels are projected to shorten the system’s payback period significantly.

Industry Adoption and Case Studies

The market for ORC systems is expanding, with notable recent projects underscoring industry confidence:

- NovaAlgoma Cement Carriers (NACC): Placed a repeat order for a HeatPower 300 system for the world’s largest cement carrier to be powered by renewable methanol.

- Jiangsu New Yangzi Shipbuilding: Selected the HeatPower 300 system for a new series of methanol dual-fuel container ships.

- Maersk: Is installing HeatPower 300 units on a series of 17,200 TEU methanol-fueled container ships built by HD Hyundai Heavy Industries.

Market Scope and Impact Analysis

Addressable Market

The potential for widespread implementation is significant, directly impacting the maritime industry’s ability to meet global climate targets (SDG 13).

- Newbuilds: The technology is suitable for approximately 30% of the 1,500–1,800 new vessels constructed annually.

- Retrofits: An estimated 8-10% of the existing global fleet of over 110,000 vessels are considered viable candidates for retrofit based on age and size.

Performance Metrics and Economic Case

The effectiveness of an ORC installation is influenced by operational factors, including engine load, vessel speed, and seawater temperature. Vessels with high engine loads operating in colder climates stand to benefit most. A case study of a 180,000 GT cruise ship equipped with two HeatPower 300 units estimates annual fuel savings of 480 tonnes. This quantifiable reduction in fuel consumption provides a strong economic incentive while delivering on the promise of responsible consumption (SDG 12) and climate action (SDG 13).

Analysis of Sustainable Development Goals in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

The article on Organic Rankine Cycle (ORC) waste heat recovery systems in the shipping industry directly addresses or connects to the following Sustainable Development Goals (SDGs):

- SDG 7: Affordable and Clean Energy – The core topic of the article is improving energy efficiency by harnessing waste heat to generate electricity. This directly contributes to making energy use more sustainable and efficient.

- SDG 9: Industry, Innovation, and Infrastructure – The article focuses on technological innovation (ORC systems) and its application in the shipping industry. It discusses retrofitting existing vessels and designing new ones with this technology, which relates to upgrading infrastructure and promoting clean, environmentally sound technologies.

- SDG 13: Climate Action – A key benefit of the technology highlighted in the article is the reduction of CO₂ emissions. By improving fuel efficiency and reducing fuel consumption, waste heat recovery systems are a direct measure to combat climate change and its impacts.

2. What specific targets under those SDGs can be identified based on the article’s content?

Based on the article’s content, the following specific SDG targets can be identified:

- Target 7.3: By 2030, double the global rate of improvement in energy efficiency.

- The article is entirely focused on a technology designed to improve energy efficiency. It states, “Waste heat recovery is one of the most powerful and underutilized tools for improving energy efficiency,” and details how ORC systems convert wasted thermal energy into useful electricity, thereby reducing the overall energy consumption of a vessel.

- Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes.

- The article explicitly discusses the retrofitting of existing ships (“retrofits are gaining momentum”) and the integration of ORC systems into newbuilds. This represents a direct effort to upgrade industrial infrastructure (the global shipping fleet) with a clean and efficient technology to make it more sustainable.

- Target 13.2: Integrate climate change measures into national policies, strategies and planning.

- While not discussing national policies directly, the article mentions that the technology helps shipowners “maintain compliance with efficiency and emissions regulations.” These regulations are the outcome of integrated climate change policies. Furthermore, the article highlights that a new vessel featuring this technology is “expected to reduce CO₂ emissions by more than 60%,” which is a tangible climate change mitigation measure.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

Yes, the article mentions several quantitative and qualitative indicators that can be used to measure progress:

- For Target 7.3 (Energy Efficiency):

- Energy Savings Potential: “over 100 TWhth of waste heat could be harnessed” in shipping.

- Energy Generation: The ePM200 XR unit delivers “up to ~200 kW net electrical output.”

- Fuel Savings: A cruise ship could achieve “fuel savings could be 480 tonnes/year.”

- For Target 9.4 (Sustainable Infrastructure/Technology):

- Adoption Rate in New Infrastructure: The technology is suitable for “approximately 30% of the 1,500–1,800 new vessels built each year.”

- Retrofit Potential: An estimated “8 to 10% of the roughly 110,000 vessels… in the existing global fleet are considered suitable” for retrofitting.

- Specific Projects: The article cites repeat orders and selections by companies like NovaAlgoma Cement Carriers, Jiangsu New Yangzi Shipbuilding, and Maersk, indicating the rate of adoption.

- For Target 13.2 (Climate Action):

- CO₂ Emission Reduction: A new vessel is “expected to reduce CO₂ emissions by more than 60% compared to conventional vessels.”

- Compliance with Regulations: The technology helps owners “maintain compliance with efficiency and emissions regulations” and capture “CO₂ savings.”

4. Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 7: Affordable and Clean Energy | 7.3: Double the global rate of improvement in energy efficiency. |

|

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries for sustainability and adopt clean technologies. |

|

| SDG 13: Climate Action | 13.2: Integrate climate change measures into policies and planning. |

|

Source: marinelink.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0