Siemens launches Sinamics S220 drive system for Industry 4.0 – Engineering.com

Report on the Siemens Sinamics S220 Drive System and its Contribution to Sustainable Development Goals

Executive Summary

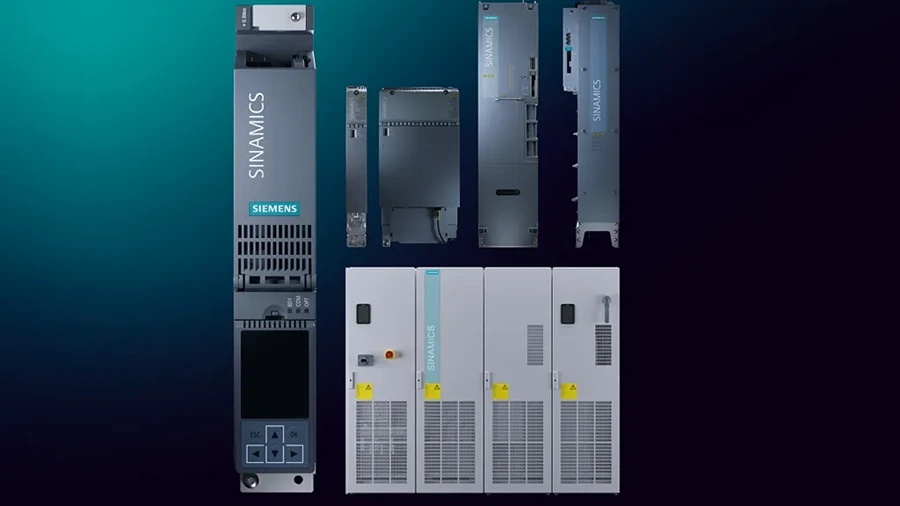

Siemens has introduced the Sinamics S220, a new high-performance drive system designed to advance industrial applications through enhanced performance, connectivity, and digital integration. As part of the Siemens Xcelerator portfolio, this system aligns with key United Nations Sustainable Development Goals (SDGs) by promoting industrial innovation (SDG 9), improving energy efficiency (SDG 7), enabling responsible production (SDG 12), and supporting climate action (SDG 13). This report details the system’s features and analyzes its contributions to building a more sustainable industrial future.

Core Technology and Innovation for Resilient Infrastructure (SDG 9)

The technological heart of the Sinamics S220 is the new CU320-3 control unit, which introduces an updated architecture for multi-axis drive control and fosters industrial innovation in line with SDG 9.

- Multi-Axis Capability: A single CU320-3 unit can operate up to 12 axes, providing a higher level of system integration and reducing hardware footprint.

- Processing Power: A built-in multicore processor delivers the high computing performance required for complex industrial tasks.

- High-Speed Data Transfer: The 1 Gbit/s Drive-Cliq-Express interface facilitates faster data exchange, improving system responsiveness and efficiency.

- Energy-Efficient Control: A test pulse method with three voltage sensors per axis enables sensorless control with accuracy comparable to encoder-based systems, enhancing both energy efficiency and operational reliability, which are cornerstones of resilient infrastructure.

Digitalization and Support for Sustainable Industrialization (SDG 9 & SDG 12)

The Sinamics S220 is engineered for seamless integration into digital workflows, supporting the principles of Industry 4.0 and contributing to sustainable industrialization (SDG 9) and responsible production (SDG 12).

- Data Generation for Predictive Maintenance: The system generates high-frequency field data, transmitted via the X128 interface, to enable predictive maintenance strategies. This minimizes downtime and reduces waste from unexpected equipment failures, supporting responsible production patterns (SDG 12).

- Virtual Commissioning: Integration with TIA Portal and DriveSim Designer allows for virtual commissioning, which streamlines engineering tasks, reduces physical prototyping, and minimizes resource consumption during the development phase.

- User Interface and Accessibility: The system offers flexible interface options to enhance usability and remote access.

- Smart Drive Interface (SDI S220) as a compact panel.

- Remote SDI Pro with a larger display and integrated web server.

- Optional Smart WiFi adapter for remote connectivity.

System Flexibility and Scalability

The Sinamics S220 drive system provides a broad performance spectrum, offering the flexibility and scalability required for diverse and evolving industrial applications.

- Voltage and Power Range: The system is available with a voltage range of 3AC 380 to 480 V, with rated currents from 3 A (1.1 kW) to 1,518 A (900 kW). This can be expanded up to 6,984 kW through parallel connection.

- Regenerative Power Supply: Regenerative active infeeds from 210 kW to 921 kW are available and can be scaled via parallel connection, improving overall energy efficiency.

- Universal Modules: Air-cooled universal modules can be flexibly operated as motor modules or active line modules, simplifying spare parts management and allowing rapid adaptation to changing requirements.

Integrated Safety and Cybersecurity for Resilient Infrastructure (SDG 9)

The Sinamics S220 establishes new standards in plant safety and cybersecurity, which are critical for building the safe and resilient industrial infrastructure promoted by SDG 9.

- Enhanced Safety Architecture: Software version 6.6 reduces the safety cycle from 12 ms to 4 ms, enabling faster reactions and higher productivity. The drive is SIL 3 certified for all operating states.

- Secure Development Process: The system was developed according to the IEC 62443-4-1 standard, independently certified by TÜV SÜD.

- Integrated Cybersecurity Features:

- User and access control mechanisms.

- Encrypted drive data to protect sensitive information.

- Integrity and authentication checks for firmware and configuration data to prevent unauthorized modifications.

Commitment to Sustainability and Climate Action (SDG 7, 12, 13)

The Sinamics S220 system is fundamentally designed to merge high performance with sustainability, directly addressing several key SDGs.

- Responsible Consumption and Production (SDG 12): The system promotes responsible resource management through a compact design that saves space, the use of resource-saving materials, and high reparability and recyclability to extend its lifecycle and minimize waste.

- Climate Action (SDG 13): The system actively contributes to climate action by enabling the capture and visualization of energy consumption and CO₂ emissions via Industrial Edge applications. Its reduced carbon impact is documented in an ISO 14021 certified Environmental Product Declaration (EPD).

- Affordable and Clean Energy (SDG 7): The drive’s high energy efficiency and regenerative capabilities reduce the overall energy consumption of industrial processes, contributing to more sustainable energy use.

Analysis of the Article in Relation to Sustainable Development Goals (SDGs)

1. Which SDGs are addressed or connected to the issues highlighted in the article?

-

SDG 7: Affordable and Clean Energy

The article highlights the drive system’s focus on “enhancing energy efficiency” and its capability to “capture and visualization of energy consumption.” This directly relates to improving energy efficiency in industrial applications, a key component of SDG 7.

-

SDG 9: Industry, Innovation and Infrastructure

The Sinamics S220 is presented as a “high-performance drive system designed for industrial applications” that supports “digital workflows” and “Industry 4.0.” Its features, such as advanced connectivity, virtual commissioning, and enhanced safety, contribute to building resilient infrastructure and fostering innovation for more sustainable industrialization.

-

SDG 12: Responsible Consumption and Production

The article explicitly states that the system is designed with “resource-saving materials” and features “high reparability and recyclability.” Furthermore, the mention of an “ISO 14021 certified Environmental Product Declaration (EPD)” underscores a commitment to sustainable production patterns and providing transparent environmental performance data over the product’s lifecycle.

-

SDG 13: Climate Action

The drive system is designed to contribute to “reducing carbon impact.” A key feature mentioned is the use of Industrial Edge applications that “enable the capture and visualization of… CO₂ emissions.” This provides industries with the tools to monitor and manage their greenhouse gas emissions, directly supporting climate change mitigation efforts.

2. What specific targets under those SDGs can be identified based on the article’s content?

-

Target 7.3: By 2030, double the global rate of improvement in energy efficiency.

The article’s emphasis on the system’s “improved efficiency” and its ability to enhance “energy efficiency” directly aligns with this target. The technology is designed to optimize energy use in industrial processes, contributing to the overall goal of improving energy efficiency.

-

Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes.

The Sinamics S220 represents a “clean and environmentally sound technology” for industrial use. Its integration into digital workflows, use of “resource-saving materials,” and focus on efficiency are all aspects of retrofitting industries to make them more sustainable, as called for in this target.

-

Target 12.2: By 2030, achieve the sustainable management and efficient use of natural resources.

The product’s design, which incorporates “resource-saving materials” and emphasizes “high reparability,” supports the sustainable management of natural resources by extending the product’s life and reducing the need for new raw materials.

-

Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.

The article’s mention of “high reparability and recyclability” directly addresses this target. Reparability helps prevent waste by allowing for component replacement instead of disposal, while recyclability ensures materials are reused at the end of the product’s life, reducing landfill waste.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

-

Energy Consumption Data:

The article explicitly states that Industrial Edge applications “enable the capture and visualization of energy consumption.” This data serves as a direct indicator for measuring improvements in energy efficiency (Target 7.3).

-

CO₂ Emissions Data:

The system’s ability to “capture and visualization of… CO₂ emissions” is a direct indicator for monitoring and reducing a company’s carbon impact, which is crucial for climate action (SDG 13).

-

Environmental Product Declaration (EPD):

The article mentions an “ISO 14021 certified Environmental Product Declaration (EPD)” which “documents its environmental performance over the entire lifecycle.” This EPD is a formal indicator that quantifies the product’s environmental impact, including resource use and recyclability, relevant to SDG 9 and SDG 12.

-

Reparability and Recyclability Rates:

The article implies these indicators by highlighting the product’s “high reparability and recyclability.” These rates, often detailed within an EPD, can be used to measure progress towards waste reduction (Target 12.5) and sustainable resource management (Target 12.2).

4. Summary Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 7: Affordable and Clean Energy | 7.3: Double the global rate of improvement in energy efficiency. | Captured and visualized energy consumption data. |

| SDG 9: Industry, Innovation and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies. | Adoption of advanced industrial drive systems; Environmental Product Declaration (EPD). |

| SDG 12: Responsible Consumption and Production | 12.2: Achieve the sustainable management and efficient use of natural resources. | Use of resource-saving materials; Reparability rates. |

| 12.5: Substantially reduce waste generation through prevention, reduction, recycling and reuse. | Recyclability rates; Reparability of the system. | |

| SDG 13: Climate Action | Contributes to corporate integration of climate change measures. | Captured and visualized CO₂ emissions data. |

Source: engineering.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0