Harnessing the bioremediation potential of indigenous Pseudomonas stutzeri for textile effluent treatment: a mechanistic insight – Nature

Executive Summary

This report details a study on the bioremediation of textile industrial effluent, a significant source of environmental pollution that poses risks to human health and ecosystems, thereby challenging the achievement of several Sustainable Development Goals (SDGs). The textile industry’s high water consumption exacerbates pressures on finite water resources, directly impacting SDG 6 (Clean Water and Sanitation). Conventional chemical treatment methods are often hazardous and produce secondary waste, failing to align with SDG 12 (Responsible Consumption and Production). This study presents a sustainable alternative by isolating, optimizing, and deploying an indigenous bacterial strain, Pseudomonas stutzeri, for industrial-scale effluent treatment. Laboratory and multi-site industrial trials in Rajasthan, India, demonstrated the strain’s high efficacy. The industrial-scale application achieved superior rates of decolorization, degradation, and detoxification of dyes, chemicals, and heavy metals. Proteomic and high-throughput analyses confirmed the molecular mechanisms and biodegradation potential of the isolate. This research highlights Pseudomonas stutzeri as a robust, scalable technology for bioremediation, promoting sustainable industrial practices and water upcycling in line with key SDGs.

Introduction: Addressing Industrial Pollution Through Sustainable Innovation

The Environmental Challenge and Alignment with SDGs

The discharge of polluted wastewater from the textile industry represents a critical environmental challenge, undermining progress towards multiple SDGs.

- SDG 6 (Clean Water and Sanitation): The industry is a major consumer of fresh water and a primary source of water pollution, contaminating water bodies with synthetic dyes, chemicals, and heavy metals.

- SDG 3 (Good Health and Well-being): Toxic, carcinogenic, and mutagenic components in untreated effluent pose severe risks to human health.

- SDG 12 (Responsible Consumption and Production): Current production patterns are unsustainable, characterized by inefficient water use and reliance on hazardous chemical treatments that generate secondary pollutants.

- SDG 14 (Life Below Water) and SDG 15 (Life on Land): Effluent discharge causes significant harm to aquatic and terrestrial ecosystems.

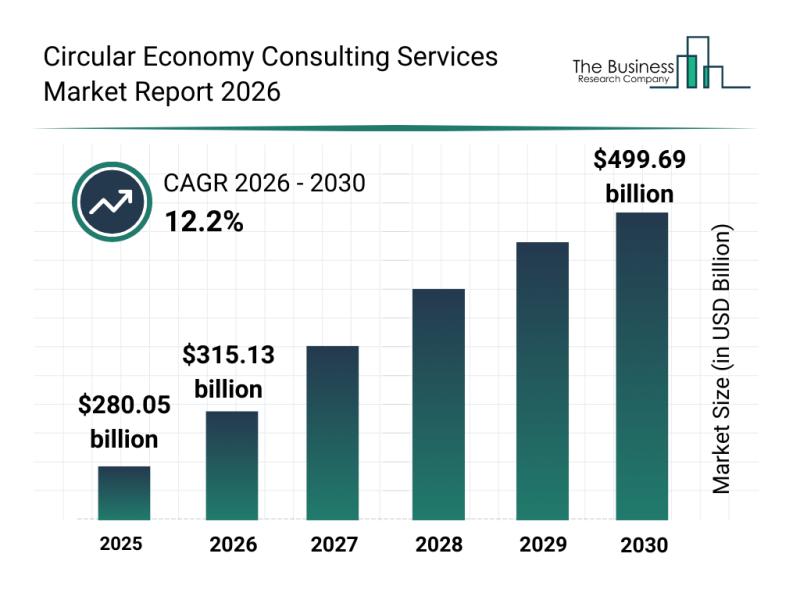

Regulatory frameworks, such as those from India’s Ministry of Environment and Forest (MoEF), mandate treatment and reuse, pushing industries towards innovative solutions that support a circular economy. Biological processes, particularly bacterial bioremediation, offer a cost-effective and eco-friendly technology to meet these standards and advance sustainable development.

Research Objectives

This study aimed to develop and validate a potent bacterial bioremediation process to support sustainable industrial practices. The primary objectives were:

- To isolate and identify a bacterial strain capable of effectively decolorizing, detoxifying, and degrading complex textile effluents.

- To optimize the strain’s performance under various physicochemical conditions.

- To elucidate the molecular mechanisms of degradation through proteomic analysis.

- To validate the technology’s efficacy at both laboratory and industrial scales, demonstrating a viable path towards achieving SDG 9 (Industry, Innovation, and Infrastructure) by providing a scalable, clean technology.

Methodology for Sustainable Bioremediation

Isolation and Identification of Bioremediation Agent

Effluent, soil, and sludge samples were collected from textile hubs in Rajasthan, India. A potent dye-degrading bacterial isolate was obtained using a modified enrichment culture method. The isolate was identified morphologically and through 16S rRNA gene sequencing as Pseudomonas stutzeri (Accession number OM133769.1).

Optimization for Enhanced Efficacy

To maximize bioremediation efficiency, key physicochemical parameters were optimized under in vitro conditions. The effects of pH, temperature, and carbon and nitrogen sources on the degradation of Acid Red dye were systematically evaluated. This step ensured the process was fine-tuned for robust performance in industrial settings, a key requirement for sustainable production patterns under SDG 12.

Proteomic Analysis for Mechanistic Understanding

Liquid Chromatography-Mass Spectrometry (LC-MS) was used for the protein profiling of Pseudomonas stutzeri under control and effluent-stressed conditions. This analysis provided critical insights into the stress-responsive proteins and adaptive mechanisms, elucidating how the bacterium manages and degrades toxic pollutants.

Effluent Treatment Trials: Laboratory and Industrial Scale

The optimized bacterial culture was used to treat effluent samples from six different textile industries.

- Laboratory-Scale Trials: Performed in 200 mL batches to establish baseline efficacy.

- Industrial-Scale Trials: Conducted on-site at six industrial facilities, treating effluent volumes ranging from 50 to 500 million litres per day (MLD).

Pre- and post-treatment samples from both trial types were analyzed using UV-Vis spectroscopy, Atomic Absorption Spectroscopy (AAS), Fourier-Transform Infrared (FT-IR) spectroscopy, and Gas Chromatography-Mass Spectrometry (GC-MS) to assess decolorization, heavy metal detoxification, and degradation of organic compounds.

Key Findings and Contributions to Sustainable Development

Efficacy of Pseudomonas stutzeri in Effluent Treatment

The study confirmed the high potential of Pseudomonas stutzeri for treating textile effluent. Under optimized conditions, the strain demonstrated significant capabilities:

- Decolorization and Degradation: Laboratory trials showed dye decolorization rates up to 98.17% and degradation of organic compounds up to 69.65%.

- Heavy Metal Detoxification: Significant reductions in heavy metal concentrations were observed, with mitigation rates reaching up to 99.9% for iron and 94.5% for copper in certain samples. This directly contributes to improving water quality (SDG 6) and reducing harm to ecosystems (SDG 14, 15).

Industrial-Scale Success and SDG Impact

The on-site industrial trials yielded superior results, confirming the technology’s scalability and real-world applicability, which is crucial for advancing SDG 9.

- Enhanced Degradation: Industrial trials achieved up to 97% degradation across the UV-Vis spectrum, indicating a more comprehensive breakdown of aromatic compounds compared to laboratory conditions.

- Superior Detoxification: Heavy metal removal was significantly higher, with 100% detoxification achieved for copper, aluminium, iron, and mercury in several industrial samples.

- Compliance with Environmental Standards: The treatment brought key physicochemical parameters (BOD, COD, TDS, TSS) within the permissible limits set by the MoEF, demonstrating a practical solution for industries to achieve regulatory compliance and contribute positively to SDG 6.

Mechanistic Insights from Proteomic and Chemical Analyses

The underlying mechanisms for the bacterium’s success were elucidated through advanced analytical techniques.

- Proteomic Response: Under effluent stress, Pseudomonas stutzeri upregulated proteins associated with detoxification and stress management, including RND family efflux transporters, chaperonins (GroEL), and enzymes for heavy metal resistance. This adaptive response is key to its survival and efficacy in toxic environments.

- Chemical Transformation: FT-IR and GC-MS analyses of treated effluent confirmed the biodegradation of complex pollutants. The disappearance of spectral peaks associated with aromatic rings and azo linkages, alongside the formation of simpler, less hazardous metabolites, provided definitive evidence of detoxification. This transformation reduces the environmental and health risks (SDG 3) associated with textile wastewater.

Conclusion and Future Directions for Sustainable Industrial Practices

This study successfully demonstrates that the indigenous bacterial strain Pseudomonas stutzeri is a highly effective and scalable agent for the bioremediation of textile industrial effluent. The successful transition from laboratory optimization to large-scale industrial application, validated by comprehensive analytical data, establishes this technology as a viable solution for sustainable wastewater management. By enabling water upcycling and mitigating pollution, this approach directly supports the achievement of SDG 6 (Clean Water and Sanitation), SDG 9 (Industry, Innovation, and Infrastructure), and SDG 12 (Responsible Consumption and Production). The patented process provides industries with an eco-friendly and cost-effective alternative to conventional chemical treatments, promoting a circular economy for water resources. Future research will focus on elucidating the complete metabolic pathways and conducting bioassays to further confirm the ecological safety of the treated effluent, reinforcing its role in building a sustainable industrial future.

Analysis of Sustainable Development Goals in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

The article addresses several Sustainable Development Goals (SDGs) by focusing on an innovative, eco-friendly solution to industrial water pollution. The primary SDGs connected to the issues are:

- SDG 6: Clean Water and Sanitation: This is the most central SDG. The article directly tackles the problem of water pollution from textile industrial effluent, which is described as a “significant source of environmental pollution” and a major consumer of water. The entire study is about developing and implementing an effective wastewater treatment system to clean polluted water and enable its reuse (“water upcycling”).

- SDG 12: Responsible Consumption and Production: The article highlights the unsustainable production patterns of the textile industry, which generates “voluminous effluent” laden with hazardous dyes, chemicals, and heavy metals. By developing a bioremediation process that is more eco-friendly and produces less secondary waste (“lower sludge production”) than traditional chemical methods, the study promotes sustainable management and efficient use of natural resources.

- SDG 9: Industry, Innovation, and Infrastructure: The research focuses on creating an innovative and scalable technology to make industrial processes more sustainable. The successful implementation of the *Pseudomonas stutzeri* treatment at an “industrial scale” demonstrates a clean and environmentally sound technological upgrade for the textile industry, moving away from “hazardous” chemical processes.

- SDG 3: Good Health and Well-being: The article explicitly states that textile effluent poses “serious risks to human health” and that its toxic metabolites are “often carcinogenic, mutagenic, and hazardous.” By detoxifying the effluent and removing these harmful components, the technology contributes to reducing illnesses and deaths caused by water pollution and chemical contamination.

- SDG 14: Life Below Water & SDG 15: Life on Land: The article mentions that inappropriate disposal of effluent is “hazardous to flora and fauna, further aggravating global environmental problems.” Treating the effluent before it is discharged into water bodies or contaminates soil and sludge directly contributes to protecting and restoring freshwater ecosystems (SDG 15) and preventing pollution of marine environments (SDG 14).

2. What specific targets under those SDGs can be identified based on the article’s content?

Based on the article’s focus, the following specific SDG targets can be identified:

- Target 6.3: By 2030, improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials, halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally.

- Explanation: The study’s primary objective is to treat textile effluent to remove pollutants like dyes, chemicals, and heavy metals. The successful “decolorization, degradation, detoxification and mitigation of hazardous components” directly contributes to improving water quality and reducing the release of hazardous materials. The mention of “water upcycling” aligns with the goal of increasing reuse.

- Target 12.4: By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle… and significantly reduce their release to air, water and soil to minimize their adverse impacts on human health and the environment.

- Explanation: The research provides a method for the environmentally sound management of hazardous chemical waste from the textile industry. By using a bacterial strain to biodegrade and detoxify the effluent, the study presents a solution to reduce the release of these chemicals into water and soil, thereby minimizing their impact on health and ecosystems.

- Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes…

- Explanation: The article presents microbial bioremediation as a “robust and scalable technology” and an “eco-friendly” alternative to conventional “hazardous” chemical treatments. Its successful application at an industrial scale represents a direct effort to retrofit the textile industry with a cleaner, more sustainable process.

- Target 3.9: By 2030, substantially reduce the number of deaths and illnesses from hazardous chemicals and air, water and soil pollution and contamination.

- Explanation: The article identifies the presence of “harmful components like heavy metals” and “carcinogenic, mutagenic, and hazardous” metabolites in untreated effluent. The detoxification process, which removes these substances, directly addresses the goal of reducing human health risks associated with exposure to polluted water and soil.

- Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.

- Explanation: The article notes that conventional chemical treatments “generate copious amount of sludge as secondary waste.” In contrast, the proposed biological process has the “added advantage of lower sludge production,” thus contributing to the reduction of overall waste generation from the treatment process itself.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

Yes, the article mentions and uses several quantitative and qualitative indicators to measure the effectiveness of the bioremediation process, which in turn measure progress towards the SDG targets.

- Percentage of Decolorization and Degradation: This is a primary indicator used throughout the study, measured by UV-Vis spectrometry. The article reports degradation rates of “up to 97%,” which directly measures the improvement in water quality (Target 6.3).

- Reduction in Heavy Metal Concentrations: The study uses Atomic Absorption Spectroscopy (AAS) to measure the concentrations of heavy metals like Copper, Zinc, Iron, and Mercury before and after treatment. The reported percentage reductions (e.g., “100% detoxification was achieved for several metals”) serve as a direct indicator of the removal of hazardous chemicals (Targets 6.3, 12.4, 3.9).

- Physicochemical Water Quality Parameters: The article measures several standard parameters to assess water quality. These include:

- Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD): The reduction of COD and BOD to within the “compliance limit set by MoEF” is a key indicator of reduced water pollution.

- Total Dissolved Solids (TDS) and Total Suspended Solids (TSS): The measurement and reduction of TDS and TSS also indicate improved water quality.

- pH levels: The article notes that the treatment reduces the pH of the effluent to a “near neutral range (7–8),” an important indicator of water quality improvement.

- Analysis of Degraded Metabolites: The use of FT-IR and GC-MS to identify the breakdown of complex organic pollutants into simpler, less toxic compounds is a sophisticated indicator. It confirms that the treatment is not just removing color but is fundamentally altering the chemical composition of the effluent to make it less hazardous (Target 12.4).

- Reduction in Sludge Generation: The article implies a reduction in waste by stating that biological processes have the “advantage of lower sludge production” compared to chemical methods. This serves as a qualitative indicator for waste reduction (Target 12.5).

4. Summary Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 6: Clean Water and Sanitation | 6.3: Improve water quality by reducing pollution and treating wastewater. |

|

| SDG 12: Responsible Consumption and Production | 12.4: Achieve environmentally sound management of chemicals and wastes.

12.5: Substantially reduce waste generation. |

|

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade industries with clean and environmentally sound technologies. |

|

| SDG 3: Good Health and Well-being | 3.9: Reduce illnesses from hazardous chemicals and water pollution. |

|

| SDG 14 & 15: Life Below Water & Life on Land | 14.1: Reduce marine pollution from land-based activities.

15.1: Conserve and restore freshwater ecosystems. |

|

Source: nature.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

;Resize=620#)