Global 2,3-Butanediol Market Outlook 2031: Industrial – openPR.com

Market Analysis of 2,3-Butanediol: A Report on Sustainable Industrial Growth

Market Overview and Contribution to Sustainable Development Goals (SDGs)

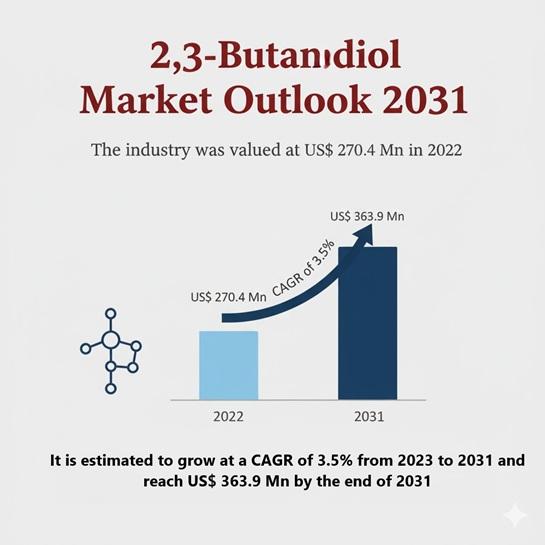

The global 2,3-Butanediol (2,3-BDO) market was valued at US$ 270.4 million in 2022 and is projected to reach US$ 363.9 million by 2031, expanding at a Compound Annual Growth Rate (CAGR) of 3.5%. This growth is underpinned by a significant industrial shift towards bio-based chemicals, aligning with several United Nations Sustainable Development Goals (SDGs). The transition from traditional petrochemical pathways to biotechnological production methods directly supports SDG 12 (Responsible Consumption and Production) by utilizing renewable feedstocks and promoting circular economy models. Furthermore, this evolution fosters innovation in green chemistry, contributing to SDG 9 (Industry, Innovation, and Infrastructure) by building resilient and sustainable industrial processes.

Key Market Drivers and Alignment with Global Sustainability Targets

The market’s expansion is driven by several factors that are intrinsically linked to global sustainability objectives.

- Industrial Demand for Chemical Intermediates: 2,3-BDO is a critical precursor for butadiene (used in synthetic rubber) and methyl ethyl ketone (MEK), a widely used industrial solvent. Growing demand from the automotive and manufacturing sectors supports industrialization, while the push for greener supply chains encourages sustainable production methods, in line with SDG 9.

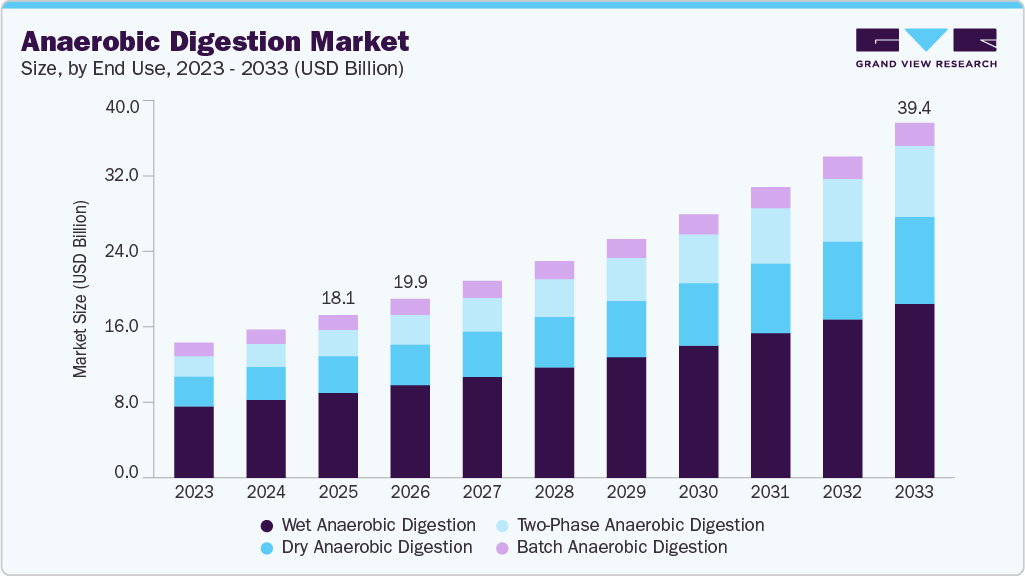

- Transition to Bio-Based Production: The increasing adoption of microbial fermentation to produce 2,3-BDO is a primary driver. This method reduces dependence on fossil fuels and lowers carbon emissions, directly addressing SDG 13 (Climate Action). The use of renewable feedstocks such as agricultural biomass and industrial byproducts reinforces the principles of SDG 12.

- Applications in Consumer Goods: The role of 2,3-BDO in food, pharmaceuticals, and cosmetics reflects a growing consumer preference for safe, natural, and sustainably sourced ingredients. Its use as a precursor for food flavorings and as a humectant in cosmetics supports SDG 3 (Good Health and Well-being) by providing eco-friendly product alternatives.

Market Challenges and Barriers to Sustainable Adoption

Despite its alignment with sustainability goals, the market faces challenges that impede the widespread adoption of bio-based 2,3-BDO.

- High Production Costs: Bio-based production via fermentation remains cost-intensive due to expensive feedstocks, complex purification processes, and the need for advanced bioprocessing equipment. This economic barrier can slow the transition away from less sustainable alternatives.

- Competition from Petrochemical Alternatives: The availability of cheaper petrochemical-derived 2,3-BDO presents a significant challenge, particularly in price-sensitive industries. This competition hinders the market penetration of greener products, delaying progress towards achieving SDG 12 and SDG 13.

- Technological and Purity Hurdles: Achieving high yields and purity levels required for pharmaceutical and food-grade applications through fermentation is technologically complex. Overcoming these hurdles is essential for advancing the sustainable innovation goals outlined in SDG 9.

Technological Advancements Fostering Sustainable Industrial Innovation

Technological innovation is critical to overcoming market challenges and accelerating the adoption of sustainable 2,3-BDO production. These advancements are central to achieving SDG 9.

- Metabolic and Genetic Engineering: Advances in synthetic biology are enabling the development of engineered microorganisms with higher production yields and greater tolerance to diverse feedstocks. This innovation improves the economic viability and efficiency of bio-based manufacturing.

- Downstream Processing Improvements: New purification techniques, including membrane filtration and vacuum distillation, are reducing the energy consumption and environmental impact of the production process. This progress contributes to SDG 7 (Affordable and Clean Energy) by making industrial processes more energy-efficient.

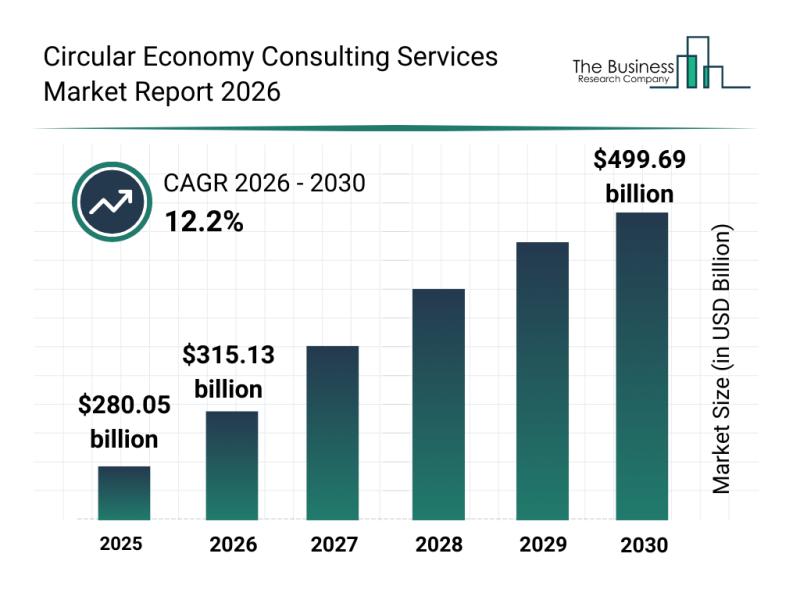

- Integration with Circular Economy Models: A key trend is the use of waste materials, such as crop residues and industrial byproducts, as feedstock for fermentation. This strategy transforms waste into valuable chemicals, embodying the principles of a circular economy and directly supporting the resource efficiency targets of SDG 12.

Analysis of Sustainable Development Goals in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

- SDG 9: Industry, Innovation and Infrastructure: The article focuses on technological advancements in the chemical industry, specifically the shift from traditional petrochemical processes to innovative bio-based production methods like microbial fermentation. It highlights investments in “microbial strain engineering, fermentation optimization, and improved purification methods” to make industrial processes more sustainable.

- SDG 12: Responsible Consumption and Production: This goal is central to the article’s theme. The transition to “bio-based 2,3-BDO” produced from renewable resources reflects a move towards sustainable production patterns. The article explicitly mentions the adoption of “circular economy models, where waste materials and renewable resources are converted into valuable chemical intermediates,” which directly addresses responsible production.

- SDG 13: Climate Action: The article connects the shift to bio-based chemicals with climate goals. It states that biotechnological methods are being adopted due to “rising concerns over fossil fuel dependency and environmental impact.” It also mentions that governments are implementing “policies to reduce carbon emissions,” which drives the industry towards greener alternatives.

2. What specific targets under those SDGs can be identified based on the article’s content?

- Target 9.4: “By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes…” The article describes the industry’s adoption of “biotechnological production methods” and “fermentation technologies” as cleaner alternatives to “petrochemical pathways.” This represents a retrofitting of the chemical industry with more sustainable technology.

- Target 12.2: “By 2030, achieve the sustainable management and efficient use of natural resources.” The article highlights the use of “renewable feedstocks such as agricultural biomass, corn sugar, and industrial byproducts” for producing 2,3-BDO. This shift away from fossil fuels towards renewable and waste-based resources is a direct application of this target.

- Target 12.4: “By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle… and significantly reduce their release to air, water and soil to minimize their adverse impacts on human health and the environment.” The move towards “green chemicals” and “bio-based production pathways” is aimed at achieving lower environmental impact compared to traditional petrochemical synthesis, aligning with the goal of environmentally sound chemical management.

- Target 12.5: “By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.” The article discusses the integration of 2,3-BDO production within “circular economy frameworks” where manufacturers use “waste materials, crop residues, and low-cost biomass as feedstock.” This strategy directly contributes to reducing waste by converting it into a valuable product.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

- Market Growth of Bio-based Chemicals: The projected growth of the 2,3-butanediol market, from “US$ 270.4 Mn in 2022” to “US$ 363.9 Mn by 2031,” serves as a quantitative indicator for the adoption of cleaner technologies (Target 9.4). The increasing market share of bio-based chemicals reflects a shift in industrial processes.

- Adoption of Renewable Feedstocks: The article’s mention of using “agricultural biomass, corn sugar, and industrial byproducts” is a qualitative indicator of progress towards sustainable resource management (Target 12.2) and waste reduction (Target 12.5). An increase in the volume of waste or renewable materials used as feedstock would be a direct measure of this progress.

- Investment in Green Technology: The article implies that companies are “investing in microbial strain engineering, fermentation optimization, and improved purification methods.” The level of investment in research and development for these green chemistry technologies can be used as an indicator of the industry’s commitment to sustainability (Target 9.4).

- Implementation of Government Policies: The reference to “governments worldwide implement policies to reduce carbon emissions and encourage green chemistry” is an indicator of progress towards integrating climate action into national strategies (relevant to SDG 13). The existence and enforcement of such policies drive the market changes described.

Summary Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 9: Industry, Innovation and Infrastructure | 9.4: Upgrade industries to make them sustainable and adopt clean and environmentally sound technologies. |

|

| SDG 12: Responsible Consumption and Production |

12.2: Achieve sustainable management and efficient use of natural resources.

12.4: Achieve environmentally sound management of chemicals. 12.5: Substantially reduce waste generation through reuse. |

|

| SDG 13: Climate Action | 13.2: Integrate climate change measures into national policies and planning. |

|

Source: openpr.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

;Resize=620#)