Industrial Radiography and smart inspection in industry 4.0 – Inspenet

Report on the Evolution of Industrial Radiography and its Alignment with Sustainable Development Goals

This report details the technological evolution of industrial radiography, from its foundational principles to its current state as an intelligent, data-driven inspection methodology. It places significant emphasis on how this transformation aligns with and supports the United Nations’ Sustainable Development Goals (SDGs), particularly in the areas of industrial innovation, worker safety, and environmental responsibility.

1.0 Historical Development and Early Limitations

Industrial radiography originated with the discovery of X-rays in 1895 by Wilhelm Conrad Röntgen. Its application expanded in the early 20th century as a non-destructive testing (NDT) method for analyzing metallic materials. Following World War II, it became a standard for quality control in critical sectors such as manufacturing, refineries, and pipeline construction, ensuring the structural integrity of essential infrastructure.

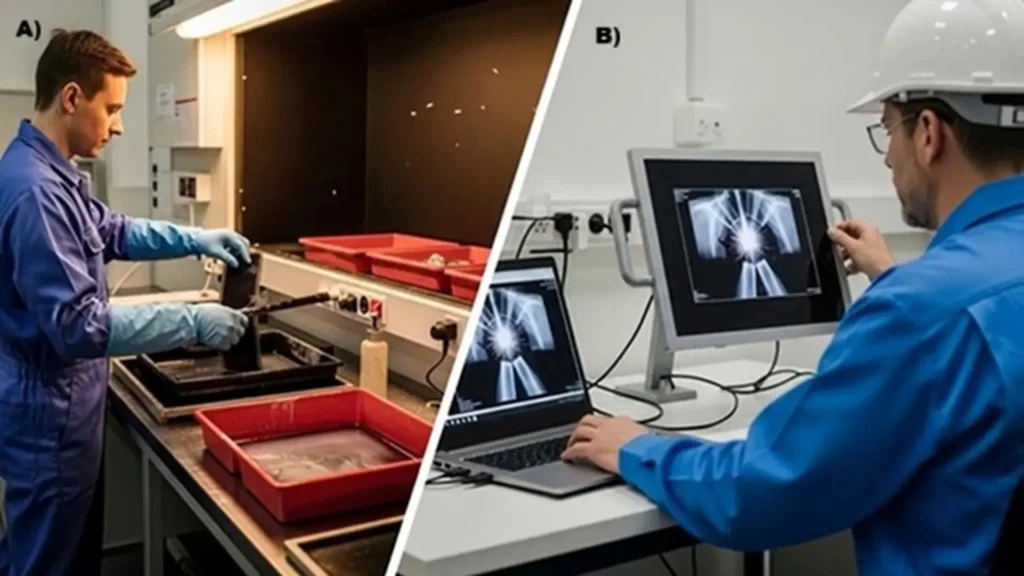

1.1 Traditional Film-Based Radiography

For decades, film-based radiography was the dominant technique. While reliable, it presented significant operational and environmental challenges:

- Extended Processing Times: The method required lengthy exposure and chemical development in darkrooms.

- Occupational Health Risks: Inspectors faced increased exposure to ionizing radiation and hazardous chemicals, conflicting with SDG 3 (Good Health and Well-being) and SDG 8 (Decent Work and Economic Growth).

- Environmental Impact: The process generated chemical waste and involved complex physical record-keeping, posing challenges to SDG 12 (Responsible Consumption and Production).

2.0 The Transition to Digital Radiography: A Leap in Sustainability and Efficiency

The limitations of film radiography catalyzed the shift toward digital imaging, a pivotal change that enhanced safety, efficiency, and environmental performance. This transition is a clear example of progress toward SDG 9 (Industry, Innovation, and Infrastructure) by building resilient and technologically advanced industrial systems.

2.1 Computed Radiography (CR)

Computed Radiography served as a bridge from analog to digital methods. It utilizes phosphor imaging plates that are scanned to create a digital image. The key benefits include:

- Significant reduction in chemical waste, directly supporting SDG 12.

- Digital image manipulation, which reduces the need for re-exposures and minimizes radiation doses for personnel, aligning with SDG 3 and SDG 8.

2.2 Direct Radiography (DR)

Direct Radiography represents a further advancement, using flat-panel detectors to provide instantaneous digital images. This technology offers superior benefits:

- Real-time Results: Immediate image visualization allows for rapid decision-making and significantly reduces inspection time.

- Enhanced Safety: Shorter exposure times drastically lower radiation risk for operators.

- Environmental Responsibility: DR completely eliminates the need for film and processing chemicals, making it a sustainable inspection solution in line with SDG 12.

- Data Management: Digital archiving simplifies storage, retrieval, and remote collaboration, improving traceability and operational efficiency.

3.0 Advanced Imaging and Data-Driven Inspection

Modern radiography has evolved beyond 2D imaging to include advanced techniques that provide deeper insights, further strengthening the reliability of critical infrastructure as envisioned in SDG 9 and SDG 11 (Sustainable Cities and Communities).

3.1 Real-Time Radiography (RTR) and Computed Tomography (CT)

RTR allows for the live inspection of components during operation, minimizing downtime and improving process reliability. Computed Tomography (CT) takes this further by reconstructing thousands of 2D images into a detailed 3D model, enabling precise visualization of internal structures. While powerful, these technologies require significant investment in data storage and specialized expertise, highlighting the need for continued innovation and workforce development under SDG 8.

3.2 Automation and Robotics in Radiographic Testing

The integration of robotics and automated radiographic testing (ART) addresses the need for faster and safer inspections in complex industrial environments. Robotic crawlers equipped with digital detectors can inspect extensive pipelines and vessels without disrupting operations.

This automation directly contributes to key SDGs:

- SDG 3 (Good Health and Well-being): It eliminates human exposure to radiation by removing personnel from hazardous inspection zones.

- SDG 8 (Decent Work and Economic Growth): It creates safer working conditions and shifts human roles toward higher-value data analysis and system oversight.

- SDG 9 (Industry, Innovation, and Infrastructure): It enables continuous and precise monitoring of infrastructure, enhancing its resilience and preventing catastrophic failures.

4.0 The Future Trajectory: Intelligent and Predictive Inspection

The future of industrial radiography is defined by its integration with Industry 4.0 technologies, such as Artificial Intelligence (AI) and digital twins. AI-powered algorithms can automatically detect and classify defects, learning from historical data to improve accuracy and consistency. When this data is fed into a digital twin of an asset, it enables predictive maintenance strategies.

This data-driven, predictive model transforms inspection from a reactive measure to a proactive tool for asset management. It supports a circular economy model by extending asset lifecycles and preventing resource-intensive failures, aligning with the principles of SDG 12. The creation of smarter, safer, and more connected industrial ecosystems helps build the resilient infrastructure required by SDG 9.

5.0 Regulatory Framework and Human Capital Development

The integrity of radiographic inspections is upheld by a stringent regulatory framework. International standards like ISO 9712 and guidelines such as ASNT SNT-TC-1A ensure that inspections are performed by qualified and certified professionals. These standards are crucial for maintaining safe work environments (SDG 8).

The digital transformation also necessitates a shift in workforce skills. The modern inspector requires a hybrid expertise combining NDT principles with data analysis and IT knowledge. Investment in training and certification programs is essential to develop the human capital needed to manage these advanced systems, fostering decent work and economic growth (SDG 8).

6.0 Conclusion

The evolution of industrial radiography from a film-based process to an intelligent, data-driven discipline is a testament to industrial innovation. This transformation provides significant benefits in efficiency, accuracy, and reliability. More importantly, it demonstrates a strong alignment with multiple Sustainable Development Goals. By reducing environmental impact (SDG 12), enhancing worker safety (SDG 3 and SDG 8), and building resilient and sustainable infrastructure (SDG 9 and SDG 11), modern industrial radiography has become a critical enabler of a safer and more sustainable industrial future.

Analysis of Sustainable Development Goals in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

-

SDG 3: Good Health and Well-being

- The article emphasizes the health and safety of workers in the industrial radiography field. It repeatedly highlights how the transition from traditional film to digital and automated radiography reduces personnel’s exposure to harmful ionizing radiation, directly contributing to safer working conditions and better health outcomes.

-

SDG 8: Decent Work and Economic Growth

- This goal is addressed through the focus on occupational safety. The article describes how new technologies “protect personnel and the environment” and “eliminate human exposure to radiation.” This aligns with the promotion of safe and secure working environments, a key aspect of decent work.

-

SDG 9: Industry, Innovation, and Infrastructure

- This is the most central SDG in the article. The text details the technological evolution of industrial radiography, from film to digital systems, robotics, and AI. This innovation is crucial for building and maintaining resilient and reliable infrastructure, such as pipelines and refineries, by ensuring their structural integrity and preventing failures.

-

SDG 12: Responsible Consumption and Production

- The article connects to this goal by discussing the environmental benefits of moving away from traditional radiography. It explicitly states that eliminating “film and chemicals offers significant environmental benefits” and that computed radiography “drastically reduces the use of chemicals,” which supports more sustainable industrial processes and the sound management of waste.

2. What specific targets under those SDGs can be identified based on the article’s content?

-

Under SDG 3: Good Health and Well-being

- Target 3.9: By 2030, substantially reduce the number of deaths and illnesses from hazardous chemicals and air, water and soil pollution and contamination. The article’s focus on reducing and eliminating worker exposure to ionizing radiation directly relates to minimizing illnesses caused by hazardous occupational conditions.

-

Under SDG 8: Decent Work and Economic Growth

- Target 8.8: Protect labour rights and promote safe and secure working environments for all workers. The article describes how digital and automated radiography create safer work environments by offering “reduced radiation exposure” and systems that “eliminate human exposure to radiation.”

-

Under SDG 9: Industry, Innovation, and Infrastructure

- Target 9.1: Develop quality, reliable, sustainable and resilient infrastructure. The entire purpose of industrial radiography, as described, is to verify the “structural integrity” and ensure the “long-term reliability” of critical infrastructure.

- Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies. The shift from chemical-based film radiography to digital methods is a clear example of adopting a cleaner, more efficient, and environmentally sound technology in an industrial process.

- Target 9.5: Enhance scientific research, upgrade the technological capabilities of industrial sectors. The article is a narrative of continuous technological upgrades in the non-destructive testing (NDT) industry, from computed radiography to direct radiography, robotics, and AI integration.

-

Under SDG 12: Responsible Consumption and Production

- Target 12.4: By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle… and significantly reduce their release to air, water and soil. The article directly supports this by highlighting that the transition to digital radiography leads to a “drastic reduction in the use of chemicals” and the “elimination of film and chemicals,” contributing to less industrial waste and pollution.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

- Reduction in worker exposure to radiation: This is a key indicator for progress towards Targets 3.9 and 8.8. The article repeatedly mentions benefits like “lower exposure,” “reduced radiation exposure,” and automated systems that “eliminate human exposure to radiation.”

- Increased inspection efficiency and speed: This serves as an indicator for Target 9.4. The article provides a specific example where automated inspection reduced “inspection time to less than half compared to conventional methods,” showcasing a tangible gain in resource-use efficiency. Other mentions include “faster turnaround” and processes that take “minutes” instead of “hours.”

- Elimination or reduction of chemical and film waste: This is a direct indicator for Target 12.4. The article explicitly states that digital radiography offers “significant environmental benefits” by “eliminating film and chemicals” and that computed radiography “drastically reduces the use of chemicals.”

- Adoption rate of digital and automated technologies: This acts as an indicator for Target 9.5. The article describes the industry-wide “transition from film to digital workflows” and the increasing integration of “robotics, digital sensors, and advanced software,” which can be measured to track technological upgrades.

4. Summary of Findings

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 3: Good Health and Well-being | 3.9: Substantially reduce illnesses from hazardous exposures. | Reduced levels of ionizing radiation exposure for inspectors and personnel, as stated by the article’s mention of “lower exposure” and “reduced radiation exposure.” |

| SDG 8: Decent Work and Economic Growth | 8.8: Promote safe and secure working environments for all workers. | Implementation of automated systems that “eliminate human exposure to radiation,” creating safer working conditions. |

| SDG 9: Industry, Innovation, and Infrastructure |

9.1: Develop quality, reliable, and resilient infrastructure.

9.4: Upgrade industries with clean and environmentally sound technologies. 9.5: Enhance scientific research and upgrade technological capabilities. |

Improved accuracy in detecting defects to ensure “long-term reliability” of infrastructure.

Reduction in inspection time (“to less than half compared to conventional methods”) and increased efficiency. Rate of adoption of digital, robotic, and AI-driven inspection technologies across the industry. |

| SDG 12: Responsible Consumption and Production | 12.4: Achieve the environmentally sound management of chemicals and all wastes. | Quantifiable reduction in the use of processing chemicals and the “elimination of film,” leading to less hazardous waste from industrial processes. |

Source: inspenet.com

What is Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0